The Mechanical Shooter

Relieving The Shooting Burden From Ballistic Testing

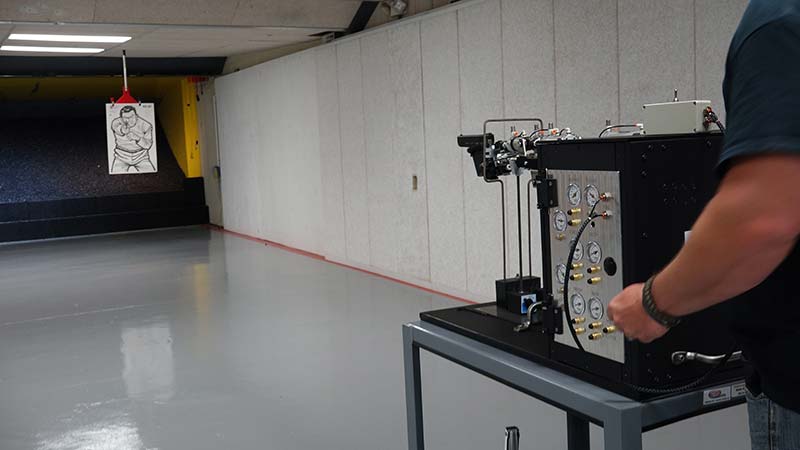

What’s the latest innovation set to revolutionize the firearms industry? It’s not a gun, or a new ammunition, or even a new accessory. It’s a new piece of test equipment called the Mechanical Shooter. It started out as a test fixture designed to relieve the shooting burden from ballistic technicians and armorers, but engineers are now finding the Mechanical Shooter can be used to make significant improvements in firearm controllability and design.

Until now, firearm controllability was measured by passing around a gun and letting different people shoot it. A consensus of opinions was used to determine results. Shooter’s opinions are pretty subjective, and for fine tuning a design — useless. Take for example, a muzzle brake. The sizes, shapes, location and number of ports all have an effect on recoil and controllability, but shooters are only able to detect major design changes. Small, yet potentially beneficial changes go unnoticed and therefore are not further exploited.

Birth Of The Mechanical Shooter

The need for a Mechanical Shooter originated at the Department of Homeland Security (DHS), U.S. Immigration and Customs Enforcement (ICE), Office of Firearms and Tactical Programs (OFTP). The OFTP is responsible for maintaining firearms and supplying ammunition to more than 70,000 agents including those from ICE, Customs and Border Protection, Federal Protective Services and the Federal Air Marshal Service. Each time there’s a competitive procurement for a new firearm, their personnel endurance-test the firearm design by firing up to 10,000 rounds each on three to six guns per competing vendor. Ammunition carried by armed DHS officers is also rigorously tested before any is ever issued to the officer in the field. In addition to procuring weapons and ammunition, the OFTP performs firearms rebuilds and resolves problems with malfunctioning guns or ammunition issues. All of which require test firing.

If you consider the amount of ammunition and number of guns tested it is not unusual for a test crew member to fire over 2,000 rounds per day. These technicians and armorers are a special breed. They love their jobs and a majority of them are avid sports shooters even though it’s their job to fire guns all day every day. In spite of their enthusiasm for shooting, injuries from extensive firing sessions were becoming a serious issue. Tendonitis forced a well-known armorer into retirement and older shooters complained their arthritis was acting up after long shooting sessions. Lowell Johnson, the Supervisory Engineer at the OFTP, decided something had to be done. Could a mechanical device be designed to ease the burden of the OFTP shooters?

Since much of their required shooting is un-aimed fire of a large number of rounds, the device might not have to be too elaborate. It couldn’t be just a clamp to hold a gun. If it was to be used for firearm evaluation, the mechanical device would be required to have all of the characteristics of a real shooter. It would hold the gun the same way, pull the trigger the same way, and recoil with the same characteristics of an actual shooter. A wide range of body frame sizes would also have to be taken into account. The device would have to operate the same way, day after day. Safety was a major concern. Wild shots into the ceiling or side walls of the range could not be tolerated. Without a human finger on the trigger and a human brain directing its operation, it could be a dangerous item. Yes, there would be safety concerns but the need for such a device was evident.

Lowell scoured the world to find the device. The Ransom Rest is extremely useful for pistol accuracy testing as it removes the human shooter from the loop. However it does not hold the weapon and recoil in the same manner as a human. Beyond the Ransom Rest, there was little else available. That’s when Lowell decided to write up his requirements into a project and submitted it to the U.S. Government’s Small Business Innovative Research (SBIR) program. Surely there was a company somewhere who would be interested in solving his problem.

It would not be an easy task since human ergonomics, safety and simplicity are not always easy to combine into a single device. To realistically emulate a human shooter, there would need to be a lot of high powered engineering to back up the design. DHS thought there may be interest from manufacturers and other government agencies as they knew the OFTP wasn’t the only one facing the problems associated with firing handguns day after day.

Several companies proposed solutions through the SBIR, with the most interesting coming from Radiance Technologies, a small, employee-owned business headquartered in Huntsville, Alabama. Radiance Technologies works primarily with the Department of Defense and specializes in providing engineering solutions to problems like the one posed by the DHS ICE.

Duplicating The Human Shooter

Radiance assigned two research engineers, Chuck Martin and Clifford McClain to the project. Both have impressive engineering backgrounds, and both are avid pistol shooters. The two saw the project as both a challenge as well as an opportunity to develop a new product for their company. In order to grasp the mechanics of what happens when a handgun fires, Chuck and Clifford began by taking high speed videos and mapping the motions of both the gun and shooter using a grid system set up behind the shooter.

Chuck showed me examples of high speed videos. I was astounded. The shooter’s recoil motion in real time was exactly what I expected, but the real eye-opener was what was happening in slow motion. Here I witnessed a huge shock wave traveling through the shooters arms and into the shoulder. The pistol acted like the handle of a bull whip. Firing resulted in an angry snap that sent the whip-like wave through the hand and arm and into the shoulder. We’ve put a link to a video showing this at the of this article.

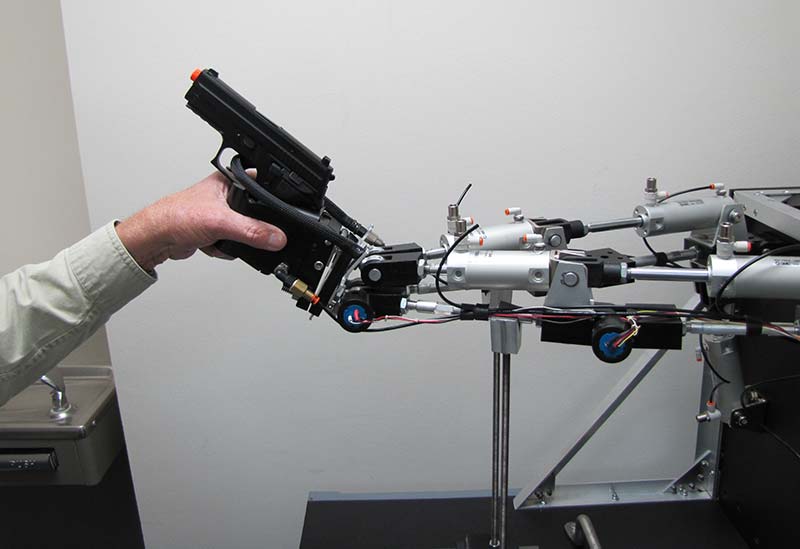

The two Radiance engineers launched into the design of what would come to be known as the Mechanical Shooter. They based the design on a model of human recoil reactions from a standing firing position with a two-hand hold. Data from people of all statures was collected and analyzed and mathematical equations of motion were developed to describe the events. From the mathematical model, wrist, elbow and shoulder joints were sized with aluminum rods to emulate bones in the arms. The shoulder attached to a tilting “backboard” for shoulder and torso response. Air pistons, air springs actually, were used to simulate human muscle groups to oppose and recover from the handgun recoil forces. By adjusting the pneumatic operating pressures and valves of the device, the recoil reactions of the various shooter types were matched with the device. The Mechanical Shooter was also designed to duplicate the so-called “limp wrist” misfeed so competing pistols could be evaluated from the same baseline.

The Mechanical Shooter features limit stops which are adjusted each time the device is set up in a range. The limit stops assure the gun will not be able to fire into the side walls or ceiling. The Mechanical Shooter is operated by one shooter but for safety reasons has two triggers so there is no chance the operators get hand parts in front of the muzzle. The Mechanical Shooter was built to evaluate and withstand handgun recoil from .22 rimfire to the mighty .500 S&W Magnum.

Handgun Control Basics?

Whenever you’re firing a handgun you are launching projectiles with lethal energy. The energy coming rearward into our bodies is the same level, but we rarely concern ourselves with the recoil motion and recoil force. Unless it’s painful, recoil management is no big deal but it’s important when you need to recover quickly to make the follow-up shot.

Maintaining control of a semi-automatic pistol during firing becomes challenging when you consider the speed of events. Your firm grip and proper stance may have you convinced the pistol is well under control during all of its cycling functions. This is far from true. After the round fires and some recoil occurs your body begins to react. The events of the slide recoiling, case ejection, feeding of a new round and return of the slide to firing position all happen in a rapid succession totaling about .05 seconds.

The human body takes about a third of a second to react to an event, so the forces from the pistol cycling events have come and gone while your body is still reacting to the first recoil action. As a matter of fact, if your semi-automatic pistol suddenly became fully automatic it could fire six more times and your body would still be reacting to the events in the first shot. The speed of the cycle events and the slow reaction time of the body clearly define the difficulty in controlling a handgun during firing.

Gun & Ammunition Testing At DHS

The Mechanical Shooter has proven to be a valuable tool for the OFTP. While the intent of the design was never to eliminate all firing done by humans, it has demonstrated the durability and versatility needed for the OFTP mission. It is particularly useful for evaluating ammunition because the firing is tedious. The Mechanical Shooter has greatly reduced shooter-induced failures which can be a problem when you consider how much firing is done by hand.

It may surprise you to learn just how much ammunition testing is required by ICE. Ammunition manufacturers compete for 5-year contracts to supply the agency. Just as with guns, typically four to eight vendors will supply ammunition for a rigorous competitive evaluation, and again the test crew springs into action, firing thousands of rounds per day during these solicitations. After a winner is declared, the manufacturer is required to submit a sample of each production batch to the OFTP. Before any duty ammunition purchased is approved to ship to the field, the sample is subjected to a lot acceptance test (LAT). This quality control check includes up to 750 rounds of function firing, accuracy and velocity testing and physical inspection.

Besides ammunition and firearms testing performed prior to purchasing by DHS, OFTP armorers fire all repaired guns to assure the repair is sound. The gunsmiths also evaluate confiscated guns—homemade or modified to determine if they are capable of firing real projectiles. The answer — gun or not a gun — is meaningful to law enforcement in determining the types of charges are filed in criminal court. Due to the many unknowns, test firing these weapons is dangerous and special precautions must be taken to assure operator safety.

Today the Mechanical Shooter is available to make firing these guns safer and less worrisome.

Is the Mechanical Shooter in Your Future?

In the original solicitation, ICE specified a Mechanical Shooter for use only as a device to shoot guns. Radiance engineers Chuck and Clifford had some additions in mind to make it even more useful. They added instrumentation to a second one capable of measuring the recoil pitch and yaw as well as to compare recoil loads. The more capable model is the one of interest to ammunition, handgun and accessory manufacturers. If the goal is to maximize handgun controllability the Mechanical Shooter provides a consistent test fixture for experiments with grips, weights, drive springs, muzzle brakes, and even tailored loads. For a real test of effectiveness, the Mechanical Shooter provides the same exact shooter with the same stance and hold every time. Measured values stop all arguments between what works, what works best and what doesn’t work at all.

Evaluating firearm controllability with mechanical devices such as the Mechanical Shooter, is a growing trend. The U.S. Army is already testing rifles and machine guns using the Weapon Recoil Simulated Shooter (WRSS) developed by Knight’s Armament Company. The WRSS compares firearm controllability on a specially designed fixture sized to duplicate the average soldier. Because body armor changes the physical characteristics of the shooter and how the shooter responds to recoil, a specially designed weight can be added to simulate the armored soldier.

Down the road, you’ll likely hear more about firearms being evaluated by mechanical devices like the Mechanical Shooter and the WRSS. Are they in your future? In the name of reduced recoil, wear and tear on the human shooter, and better controllability the answer is “yes.”