Don’t Screw Yourself … Check Your Screws!

The long-awaited anticipation of shooting a new gun is akin to waking up Christmas morning as a child. I spend days fingering it like a raccoon, checking over every nook and cranny before its maiden voyage. Chambered in my favorite caliber, the grand old .45 Colt, I couldn’t wait to shoot it.

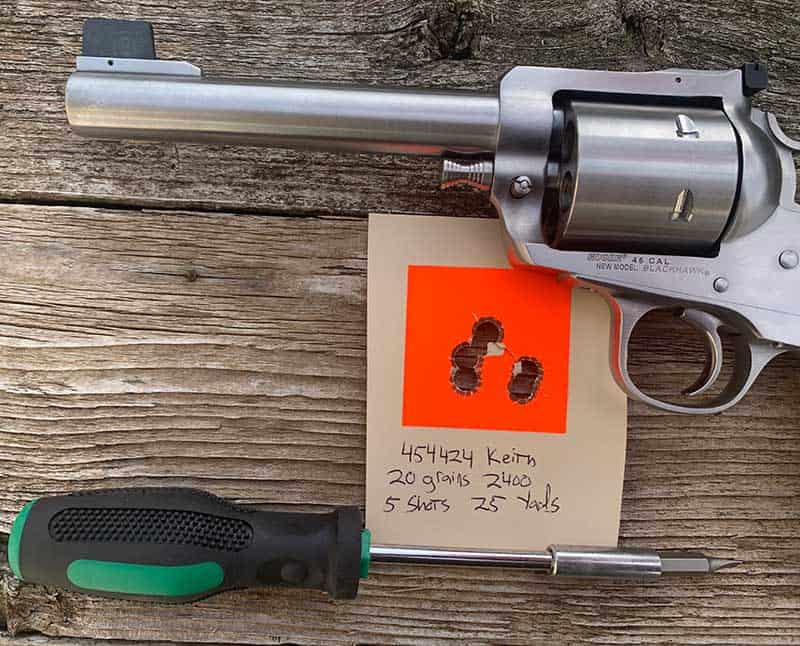

Built on a large-framed Ruger Bisley, I was using a favored heavy hunting load consisting of homegrown Lyman/Ideal 454424 cast bullets. Powder-coated and sized 0.452″, they’re seated over 20 grains of 2400 in Starline brass, sparked by a Winchester large pistol primer. I’ve killed much game with this load. I know it’s accurate and it sets a good standard.

Since I was testing for accuracy, I shot from the bench, forearms resting on a carpeted 6″x6″ block of wood. My targets were 2″ orange squares at 25 yards. The custom front sight, matched with the rear sight, provides a wonderful sight picture. While cocking the gun, I appreciated the smooth action. As the cylinder rotated, the bolt found the cylinder notch, locking it tight.

Using a 6 o’clock hold on the square, I settled into my shooting sequence. After a deep breath, I slowly exhaled, maintaining sight picture. Subconsciously, my brain told my trigger finger to begin its press. When all is settled, I feel the recoil. The trigger is crisper than biting into a red delicious apple on a fall afternoon.

The sequence is repeated four more times. Focusing on the front sight, I see a black hole appear on the 2″ orange square, growing slightly with each shot. This gun’s a shooter for sure!

Abracadabra?

With a smile of satisfaction, I extracted my brass. You know the sequence. I cradle the gun in my left hand and work the ejector rod with my right, pushing the brass into my left palm. Hmmm! That’s odd! Where’d the ejector rod go? Where’s the ejector rod housing?

I see the housing screw hole. Threaded, it’s empty. At least the screw didn’t shear off. Apparently, the housing screw backed out allowing the whole works to fly off!

Responsibility?

People tell me I’m a funny guy. Take that as you may. Now some would be mad at the gunsmith who built the gun, but I was mad at myself. During my infatuation period of fondling the gun, I should have checked all screws, making sure they were tight. In today’s world, everyone’s at fault, except for the person committing the act, right?

The thing is, I’m not from today’s world. I take responsibility for my actions, or inactions, in this case. I should have checked the screws. I take full blame. I was the shooter, it was my gun and I was there. How many of you are guilty of the same thing? How many of you degrease and then lube your shooter, whether it’s new, or “new” old to you before shooting? Say what you want, I’ll never be accused of being Alex Baldwin on so many levels.

CSI?

I wanted my parts back! Who wouldn’t? I knew they had to be somewhere. Thinking back to my accident reconstruction days as a copper, I applied the help of Sir Isaac Newton. Most likely, the parts blew off in the throes of recoil from the heavy load, meaning they probably went behind me. I started there.

It was sunny, so I was hoping to catch some glare from the stainless-steel parts. I started a precise grid pattern search, like searching for evidence at a crime scene. This gave me hope, knowing things don’t vanish into thin air. I extended my grid pattern to enormously large and unlikely projections. I checked the A-frame rafters above my head. Hey, you never know. I’ve recovered evidence in weird places before.

So, then I think, as the screw backed out, it might have flown off while aiming. Being under spring tension … I started a new grid search in front of me, downrange. Thankfully, I was the only person at the range. Again, an ever-growing search pattern came back with negative results.

Maturity?

After 45 minutes, I gave up. In the old days I’d be mad at myself, working myself over pretty well. Now? I chalk it up a learning lesson to never take anything for granted. Check your gear. If it can go wrong, it eventually will. Now I pass this incident on so you can learn from it. Check your screws. Loose screws are the cause of many problems. They’re an easy fix too, if you take the time to catch them.

As a side note, I ordered new parts from the gunsmith, offering to pay for them. Hey, it was my fault. I think he was shocked by my confession and told me not to worry about it. Life is good again.