Black Hills Ammo

Family Values — No-Compromise Quality

“Every shipment to military units is manufactured as if each cartridge had to protect a life.” This perspective helped Jeff and Kristi Hoffman start an ammunition firm before they had anything to offer the armed forces. Before, in fact, the US government needed more ammo.

After the Vietnam Conflict, demand for service ammunition dropped off. Jeff was a police officer in his hometown of Rapid City, South Dakota. “I was handloading because I liked to shoot,” he recalls, “and then to supply my friends on the force.” In 1982 he and Kristi bought into a business that 6 years later would split from Black Hills Shooter’s Supply. The Hoffmans hatched Black Hills Ammunition in a hut not much bigger than the hub of a used car lot. Inside, stacks of components shadowed loading benches bristling with presses. Navigating aisles on my first visit to BHA, I timed my steps between the swings of press handles. There was no chug of power-driven loading machines. Every round was loaded by hand!

“Much of our ammo is re-manufactured,” Jeff explained back then. “We scrounge brass wherever it’s free or affordable. We clean it up, make sure it looks and performs like new.” The building was too small to hold finished ammo, so the Hoffmans stored it outside in a shipping container, a huge metal box that, when Jeff opened it to show me, was crammed full. “We’re getting orders,” he insisted.

Ramping Up

Actually, demand for their ammunition soon out-paced the production capacity of the arm-weary crew. Law enforcement (LE) loads, then big game and target cartridges, joined the general-purpose .223 and pistol ammo. BHA brought factory-fresh brass and mechanized loading machines, then invested in a new plant. On my next visit, Jeff drove me across town to a stately building behind a strip of lawn and tall trees. The empty structure commanded a plot surprisingly big and open, given its urban address. Eerily, it reminded me of milking cows for my room and board at Michigan State U.

“Well, it is a creamery,” Jeff grinned. “But not for long.” He led through tentacles of new, empty annexes, into rooms stripped of milk tanks and plumbing. “We’ll fill these spaces.” We walked onto thick concrete loading docks, then climbed to a conference center Jeff told me would remain for meetings and visitors. “Kristi and I have offices on the main floor close to production.” He spread blueprints. Every one of the plant’s 60,000 square feet was spoken for!

LE and armed forces contracts hurried BHA through its re-purposing of the creamery. Visiting BHA in 2013, I found the grass and trees and truck-parking arena encompassed by high wire. A series of electronic precautions later, I met Jeff and Kristi in their offices, big windows opening to ranks of staff desks. This could have been an IRS center, or the command post of a shipping company. Jeff introduced me to people I’d known from the early days on the single-stage presses. Loyalty runs high at BHA. The faithful clearly like their work, the Hoffmans’ unapologetic patriotism and the growth-oriented, can-do ethic of the company. BHA’s payroll has grown to about 75 people.

Jeff ushered me onto the creamery floor. Now a fully automated ammunition plant, it throbbed to the rhythm of loading machines chugging out pallets of cartridges every hour. “Still, our quality control inspectors outnumber production people,” Jeff said. Annexes were full, and as spotless as if processing milk. “Even after the post-2008-election panic buying subsided, we kept running at capacity, sometimes blessed with the need to work overtime.”

The rush by the shooting public to stock up on handloading components during the Obama years challenged BHA and other manufacturers. “For a while it seemed as if we’d never get more brass, powder, primers and bullets than we needed to fill immediate orders,” said Mike Wright when I telephoned for an update recently. “We’re in better shape now.” Mike, who’s worked a decade at BHA, said nearly all current production is new ammunition. “We have huge supplies of .223 and .40 S&W once-fired brass, so still load them for practice ammo. We dropped remanufactured 9mm and .45 ACP loads four years ago.”

Focusing

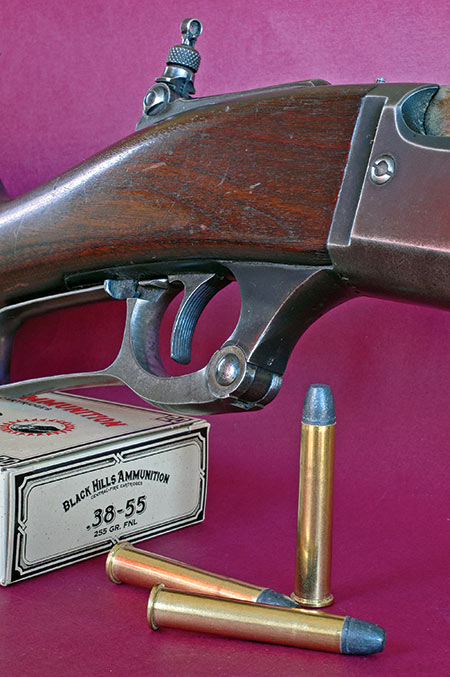

In 2012, as it filled a Navy contract for 50 million rounds of 77-gr. 5.56mm ammo, Black Hills added a 69-gr. 5.56 MatchKing load to the line. It also corked the .300 Whisper with 125-gr. spitzers to duplicate light-bullet loads in the 7.62×39. But the company gives equal effort to small-bore ammo for hunters. It’s paired the .204 Ruger with a 32-gr. Hornady V-Max and stoked a 36-gr. Barnes Varmint Grenade to 4,250 fps in the .22-250. BHA’s broad selection of .223 loads includes a 62-gr. TSX.

“We do distinguish between .223 and 5.56 ammunition,” emphasized Mike Wright. “Per SAAMI specs, the 5.56 NATO is loaded to higher pressures. You may see identical velocities in our data. That’s because we chronograph 5.56 ammo from 20″ barrels, .223 from 24″.” BHA does not recommend use of 5.56 ammo in barrels with .223 chambers.

Rifle cartridges have earned themselves more catalog space at BHA. The Black Hills Gold stable of hunting rounds comprises 41 loads in 10 chamberings, .22-250 to .338 Lapua, with bullets from Barnes and Hornady, Nosler and Sierra. Rifle loads in what might be called a target/tactical category number 31, in seven chamberings — including a 300-grain SMK in .338 Norma Magnum and a 220-grain OTM bullet at a sub-sonic 1,000 fps in the .300 Whisper.

Each loading machine is carefully attended by hand. There’s no

“set it going and walk away” at Black Hills. Operators watch

and listen for changes in sound, rhythm, cadence and such,

constantly checking output. Experience gives them expert’s

eyes and ears and they intervene at the least inkling of an issue.

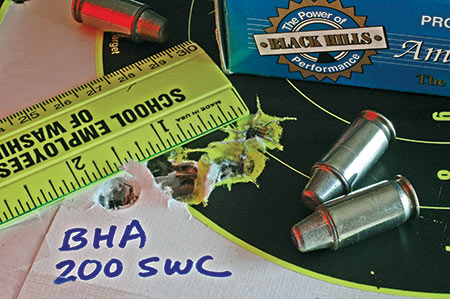

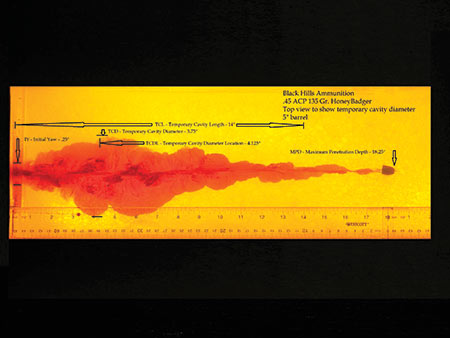

The Honey Badger

“The big news for 2017, though, is in our pistol ammo,” Mike said. “We’ve introduced the Honey Badger bullet — so named for its relentless penetration.” He told me the bullet is of solid copper, with cuts in the nose imparting radial shock to tissue. “But the nose doesn’t open or upset. Honey Badger is not an expanding bullet. It drives through car doors, glass and other tough resistance like a solid. We get 14″ to 18″ of penetration in ballistic gelatin for mid-level loads.”

Honey Badger bullets are lightweight for the bore: 60 grains in .380 Auto, 100 in .38 Special, 125 in 9mm (the latter barely subsonic). There’s also a 135-gr. offering in .45 ACP. Lust for more power? A 160-gr. .44 Magnum Honey Badger clocks 1,800 fps from a 71/2″ barrel!

Jeff Hoffman had a lot to do with the design of this bullet. He’s still active in law enforcement as a member of the Pennington County Special Response Team. His commitment to military and LE people is inked into the BHA coaster under my coffee cup: “We build sharper swords for our warriors.”

While handgun ammunition gave BHA its start, the firm pays as much attention to rifle loads. For 2017, Hornady ELD-X and ELD Match bullets replace A-Max missiles in Black Hills Gold. When Sierra capped its celebrated boat-tail hollowpoints with polymer tips, Black Hills picked them up for its 5.56 and 7.62 ammunition. I snared samples of 77-gr. 5.56 and 175-gr. 7.62 loads. For 5.56 trials I grabbed an Armalite AR-15 with a heavy 20″ fast-twist stainless barrel. The 7.62 ammo went to a rifle I’ve come to trust: a SIG SAUER SSG 3000. This bolt-action has a medium-heavy 24″ barrel.

With a CQB scope at its maximum power of 4x, I was blessed by a 3-shot knot of just under 0.4″ from the 5.56. The SIG drilled a 0.7″ group. Two additional shots opened it to 0.8″. In my experience, long bullets can show some yaw and precession at modest yardage and “go to sleep” at distance. So groups can actually improve, in minutes of angle, as such missiles cover ground. These TMK target loads should also appeal to snipers. BHA gelatin tests with the 77-grain 5.56 load in a 141/2″ barrel produced yawning cavities between 1″ and 9″ past entry, with 12″ of penetration. The 175-gr. 7.62 bullets blow football-size holes from 1″ to 13″ along a yardstick and drive deeper. The high ballistic coefficients of these bullets promise flat arcs and stubborn resistance to wind-drift.

Discriminating Markets

BHA’s pursuit of ever better ammunition trumps its desire to sell more. Since its early years, the company has courted discriminating markets. “Army specs call for 2″ groups,” Jeff told me. “That’s an average for five, 10-shot groups at 200 yards!” Of course not every .223 rifle can do that. But the rack of super-accurate test barrels at BHA helps it meet the standard. In 2000, US Army shooters began using BHA ammo in competition. Service contracts followed. “The Marines must like us, too,” Jeff confided at the time. “They just ordered 788,000 rounds.” The Navy followed suit. Jeff and Kristi and the BHA crew are openly proud of compliments they receive from Special Forces units. “They know we know every shot counts!”