Slugfest

Handgun's How-To-Guide On Bore Slugging

We frequently read we should “slug” our gun barrels so we know what we have to deal with to get the best accuracy. Jacketed bullets right at or .0005″ under groove size do just dandy. Cast bullets need to be .001″ or greater than groove diameter, or we get gas blow-by and lots of leading in the barrel. Worst of all, accuracy is usually pitiful.

For example, .452″ wheel weight bullets are just dandy in my Ruger Blackhawks with their tight chambers and .451″ bores. But accuracy is poor using them in my Rossi rifles with big chambers and .453″ bores, even when liberally coated with White Label Liquid Xlox. Sized to .454″ are okay, though, and the Rossi pounds .457+” bullets right in there close together because the larger bullets center the rounds in the chamber better. An excellent low pressure plinking load in my .457″ bore Marlin .45-70 is a .462″ 210-gr. wheel weight bullet and 11-12 grains of Unique. Hence the reason for slugging. You gotta’ find out what you’re dealing with!

Swelling Bullets?

We sometimes read about cast bullets obturating, or swelling, due to chamber pressure, filling the bore and sealing it. That can work if pressure is high enough and the metal is soft enough. The chamber pressure has to be higher than the Brinnell hardness number of the bullet times 1,440 in order to make the bullet obturate. For example, the Colt .45 has a SAAMI upper pressure limit of 14,000 psi. Divide this by 1,440, and you see your bullets cannot be any harder than BHN 91/2 for that to work.

Wheelweights run 11-12. The standard for cast bullets, against which everything else is compared, is Lyman’s #2 alloy, which is BHN 15. So you can see you’re having issues already if you’re relying on a bullet to obturate yet you’re using hard lead.

Many commercial bullet casters are proud of their bullets — which are even harder. That’s okay as long as you know your bore size and your bullets are bigger. Hard, undersize bullets are nothing but grief.

The Process

Slugging a barrel is easy. Start with a Hornady or Speer pure lead roundball a bit larger than the bore in question. If you can’t find the proper size, start out undersized, and gently flatten the ball with a hammer until it’s a bit oversized. Once started, a sturdy cleaning rod is all it takes to tap the ball down the bore. I prefer to put a cleaning jag on the rod, with the jag’s point filed off.

If you’re a bullet caster, make yourself a few from BHN 5 pure lead on up to stick-on wheelweights (BHN 9) in an appropriately large mold. I prefer using a bullet providing two or three bands to measure. A lead ball only has one.

That sturdy cleaning rod can also be used to drive bullets down the barrel, but its flexing makes me cringe. A solid aluminum or brass rod is better. Hardware store sizes run 1/4″ and 3/8″. I prefer to buy a brass rod on eBay in 5/16″ (.3125″) for .38/.357’s and 7/16″ (.4375″) for my .45’s. The 1/4″ is fine for .30 caliber rifles.

For my .45’s, I started with a 4-foot piece of 7/16″ because I have rifles with barrel lengths of 16″, 20″ and 24″. Use a measuring tape and a Sharpie to draw a line for your barrel length(s). We don’t want to drive the bullet into the bolt face if it’s not convenient to remove the bolt, like Winchester 94’s and Rossi 92’s. Allow enough extra to maintain a firm grasp on the rod, and cut off the excess. I used the leftover piece for revolvers.

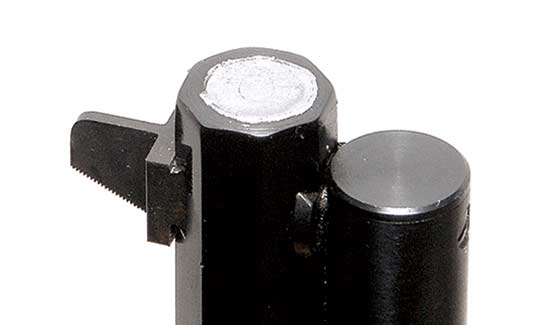

Round balls only provide one reference area to measure. Bullets give two or three. The asymmetrical skirt comes from

the bullet not starting exactly straight. When fired, the bullet does not enter the bore perfectly centered, and develops an asymmetrical skirt like this,

which does not help consistency or accuracy. These are .457+" bullets going down a .451" bore.

The Mechanics

I juice my bores with good ol’ 3-in-1 oil on a patch, then apply a ring of petroleum jelly inside the muzzle with my finger. If using a bullet instead of a ball, I liberally lube it with petroleum jelly, too. I want the thing to slide easily. Stand the firearm vertically and use a plastic or brass faced hammer to gently tap the slug flush with the bore. If using a big enough bullet, you’ll see a flange of lead form at the muzzle.

Next, use a brass punch to push the ball or slug a couple inches into the barrel. Now you can go to work with your long rod to carefully tap the slug the rest of the way. I usually put a wad of cloth in the chamber to catch the slug. By paying attention to the line on your rod, you can ease off and maintain control as you approach the point where the slug will exit the barrel. Measure it and you will know exactly what you’re dealing with. And be prepared to be surprised at what you find out at times!

For more info: www.americanhandgunner.com/index