Powder River Precision

Retro Or Modern Done Right

Most people who follow the custom pistol world — especially the XD world — are likely aware of Powder River Precision. Founded by pistolsmith Daniel Batchelor in 2007, PRP is known for its extensive line of XD products, including an innovative striker safety lever and an over-travel stop trigger that’s been OEM’d by maker Springfield Armory.

Like most companies, Powder River didn’t spring to life fully formed. The story begins in 2005 in Twenty-Nine Palms, California, where Batchelor was stationed with the US Marine Corps. Custom pistol aficionados will instantly recognize Twenty-Nine Palms as the long-time home of Bar-Sto Precision, the iconic barrel shop founded in the 1950’s by Irv Stone, and still run by son Irv III, now in South Dakota. Once Batchelor realized where he was, he drove over to Bar-Sto and introduced himself to Irv, asking him to teach him the trade.

This would prove fortuitous on a number of levels. In addition to providing a solid foundation in traditional pistolsmithing methods, Bar-Sto was one of the earliest custom shops to focus on improving the XD. At the end of his agreed-upon year at Bar-Sto, Batchelor attended a class taught by Cylinder & Slide founder Bill Laughridge to further expand his skill set. The training time under both men was well spent. When I shot the 1911 Batchelor built for Irv as a thank-you, it averaged 1.1″ at 25 yards and never malfunctioned. It’s the most accurate .45 I’ve ever had in the Ransom Rest.

Opening up shop in Baker City, Oregon, Dan quickly made a name for himself with the XD, both by working on them and producing an innovative line of parts. In addition to the striker safety lever, the line has expanded to include custom grip safeties with a 1911-style “speed bump” at the bottom as well as an extended mag catch, complete trigger kits, a punch set and traction grip decals. Never one to sit still (he’s also a sworn peace officer and licensed flight instructor), Dan is now a full member of the American Pistolsmith’s Guild and continues to build well-thought-out custom pistols for both competition and defense, in addition to his popular line of parts.

Getting Familiar

Over the last few years I’ve had the chance to spend quite a bit of time with Dan’s work, including that 1911 and a custom .40 cal XD I’ve put about 1,000 rounds through. I’ve also spent some good time with the pair of 9mm autos we’ll talk about here — a 5.25″ XDm and a Browning Hi-Power.

One of Batchelor’s personal guns, this 5.25 XD, holds 18+1 rounds of 9mm and showcases most of Powder River’s XD parts. In addition to the solid steel guide rod adding recoil-absorbing weight to the front, it has the extended ambidextrous magazine release, pebbled grip decals and a speed-bump beavertail. Not to mention the trigger. Ahh, yes, the trigger. We measured the trigger pull on the Lyman electronic trigger pull gauge sourced from Brownells and found it broke with a slight roll just under two pounds. The smooth, light break, coupled with the soft recoil, made the XDm extremely easy to shoot well — and fast. Since polymer pistols don’t fare well in the Ransom Rest, I only shot it by hand.

Even so, it acquitted itself startlingly well. I was able to shoot several groups in the 2″ range at 25 yards, two of them around 1.5″, with four of the five shots in under 1″. At seven yards, the bullets tended to make a single hole about .8″ across from center-to-center. While I’ve never been a particular fan of the XD platform, this pistol has convinced me I may be missing something.

Reliability was also superb. After switching the recoil spring to match the ammo I chose, I put over 1,000 rounds through it, 700 Atlanta Arms’ 115-grain match JHP, which proved remarkably accurate. I also fired 150 rounds of their subsonic 147-grain match JHP, in addition to a selection of loads from Black Hills. When the slide got a little sluggish at 890 rounds and started to mis-feed, I oiled it a tad, and it returned to flawless function. It was never cleaned.

Hi-Power

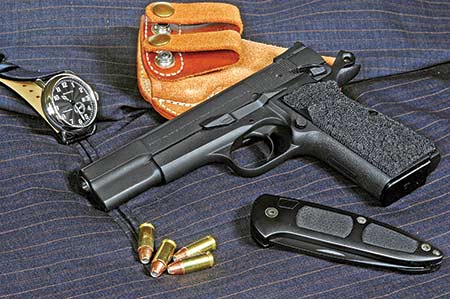

Everyone’s favorite it seems, the Hi-Power fared even better. While most guns can benefit from CNC machine work and aftermarket parts, some are still defined by hand work, and the Hi-Power is one. Think art, not engineering. This gun started life as an MK3S Browning, which, with its side extractor, forged receiver and Charles Kelsey-designed firing pin safety, probably has the best bones of the various Hi-Power models.

Cloaked in a purposeful matte black, the pins and small screws have been highly polished and fire-blued for a subtle flash of color. All sharp edges have been judiciously beveled and the sights have been replaced with a dovetail-mounted front sight with a serrated, plain black face, while the rear is a stout-looking Heinie part, also with a serrated rear face. The front is machined to present a flat face for those who use the sight-cocking technique. While I’m no fan of sight-cocking for safety reasons, the installation and modification are well done and the flat face of the sight is beautifully integrated into the curvature of the slide.

The stock barrel has been replaced by a custom Bar-Sto and controls consist of an extended slide stop and a factory thumb safety, welded-up and serrated to provide an extended contact pad. The trigger is a wide C&S unit mated to a rowel hammer dropping at 5 pounds, 7 ounces, with the slightest touch of the inevitable creep accompanying all Hi-Power triggers. Because the lever that connects the trigger and the hammer/sear is in the slide, trigger pull is dependent on the consistency of the slide’s cycling.

Hi-Power slides are also notoriously soft. Even if tightened, they shoot loose in short order, so there will virtually always be play in a Hi-Power slide. Pressing the trigger pushes up against the slide-mounted sear lever, taking up that slack. On particularly loose guns, you can actually watch the slide rock as you press the trigger. So there’s a certain amount of creep that cannot be removed from a Hi-Power, at least long-term. All that said, the trigger is excellent, as are the ergonomics.

Both the front and rear of the frame are stippled in the same pattern found on the heel of the slide. The rear tang of the frame has been welded-up and shaped into a slim, effective beavertail. For those of us with scars from hammer bite, this is a godsend. Like the 1911 before it, the spur hammer of the Hi-Power has long bitten the hand feeding it, but the combination of the round hammer and beavertail makes this one much more comfortable to shoot. The grips have likewise been stippled, but in a coarser pattern providing excellent purchase, without being uncomfortable. The work on the grip panels is so well done only the thumb rest suggests they began life as factory Hi-Power grips.

A Shooter?

It fed some 500 rounds of Black Hills 124-grain JHP, both in standard and +P loadings (plus some trashy ball at the beginning) and I never cleaned or oiled it, either. I did have a single bobble right at the end of the test but since I couldn’t place the reason for it other than just an accumulation of gunk, I think it’s more than forgivable!

While Hi-Powers can be hard to shoot for groups, after a few hundred rounds I could tear a ragged hole at closer distances. At 25 yards, the pistol averaged 2.75″ from the Ransom Rest, with a strong preference for 124-grain bullets, averaging 2.1″. Black Hills +P 124-grain JHP did particularly well, at 1.66″ which is unsurprising. I’ve been very pleased with its accuracy in my Gen 3 Glock 19 as well.

While I did not notice it shooting by hand, 115-grain loads showed significant vertical stringing spoiling what would otherwise have been some spectacular groups. My personal standard for a custom carry pistol is it should work every time and average 3″ or better at 25 yards and the Powder River Hi-Power passes that with flying colors — and style

Accomplished Work

Mastery in any field is defined by the ability to make progressively finer distinctions. A beginning shooter, for example, probably can’t tell the difference between a pistol that shoots 3″ at 25 yards and one that shoots 4″. To the trained eye, however, such subtleties of performance are noted. Indeed, the more you look at — and use — the Hi-Power, the more you see. From the understated fire bluing, an allusion to earlier gunmaking methods used in the Colt SAA and early 1911 models, to the way the fine stippling fades into the base of the trigger guard, the details are what set this gun apart. Does it work and hit? Yes. But it’s more than that — it’s art too.

With barely 10 years under his belt, Daniel Batchelor has already built a business with a canny mix of parts filling a unique niche, and pistols built with admirable craftsmanship. I expect great things to continue for Powder River Precision.