Brass

You can always spot the reloader at the range. He pads behind departing shooters who leave their brass behind or looks longingly as it hits the ground. I admit it; I am a brass hunter. At least my preoccupation is considerably more respectable than dumpster diving.

Because of this, I’ve learned a lot about the life of brass.

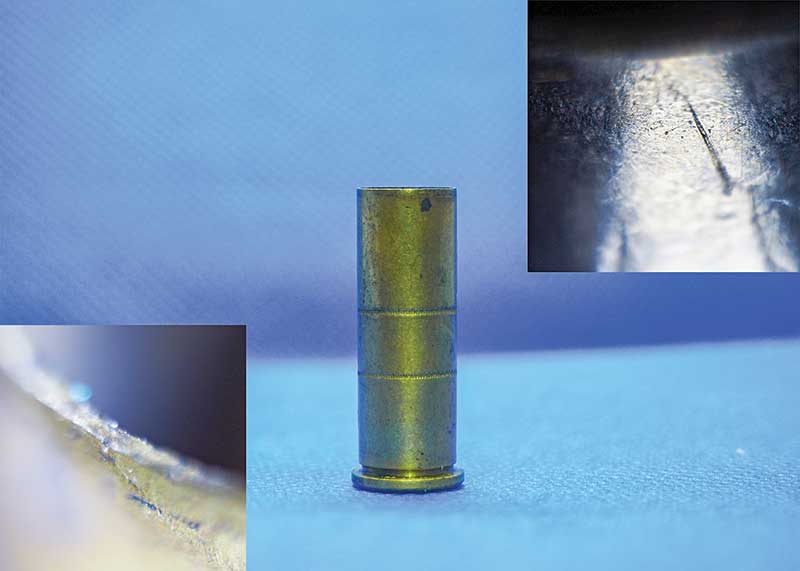

This is a 38 case that’s been reloaded a few times. On the bottom left,

notice the uneven surface and small cracks along the mouth. The uneven

surface can be detected by running the finger around the mouth. The blue area

is in one of the cracks, probably copper oxide. The top right shows a gouge

that could eventually work into a crack.

Brass Stress

The first thing I learned was that brass cracks when it’s stressed. Since I was trying to maximize the number of loads from each case, I learned everything I could about preservation.

Expanding a case mouth is essential for handgun reloading but also stresses the brass. If the case is going to crack, it often happens during expansion. This is the best time to inspect a sized case. Eyeball it and run the pad of the finger around the top. To save some wear and tear, invest in a high-quality expander die. I recommend Redding’s Titanium Carbide Pro dies.

Upon ignition, brass flows in the chamber, expanding to match the contours of the chamber. The brass can only expand in two ways: outward (a little) to fit the chamber and lengthwise. Eventually, the length will be out of spec, and you’ll need to trim it. This process, over time, causes the brass to get thinner. Eventually, it’ll crack and become useless.

Is it worth your while to trim brass, or should you use it until it fails? The answer depends on the pressure of the load, but I have found that brass is often nearing its failure point around the same time it needs trimming.

Regardless, I still trim brass. Take an honest look at your workflow and, in the words of Guro Dan Inosanto, “Research your own experience. Absorb what is useful, reject what is useless, and add what is specifically your own.”

Sort Your Brass

I sort by type, headstamp and condition. If a single lot stays together, you’re more likely to get consistent sizing, expanding and crimping with less wear. And sorted brass gives more consistent (accurate) results.

Clean Brass Is Safer

When I started reloading, dies with harder sizing buttons like carbide were less common and I had cheap dies. I used to clean my cases, one at a time, using steel wool. I skipped cleaning my cases a couple of times and the grit on my brass scored my dies. They left scratches on every case I loaded henceforth. The brass always failed early and always where it was scored.

We are spoiled now. Carbide dies are harder to score and don’t require lubricating every case for sizing. They do, however, wear faster with dirty cases. Many things we find on dirty brass, like oxidated materials, are used as abrasives to polish these things.

Cleaning Options

My best dry method for cleaning brass is a vibratory case tumbler. I have a Lyman Turbo 1200 Case Tumbler with Auto-Flo. There are several kinds of media, but the most common are corn cob and walnut hulls.

I use corn cob media with Flitz media additive. Corn cob media is lighter, making it suitable for brass just picked off the range after firing. For heavily abused brass, use walnut hulls. This media is harder, heavier and has sharper points. I do not use any type of rock polishing abrasive, which you don’t want in your dies.

Washing brass can remove oils and chemical coatings used for sizing operations. Be aware some copper cleaning solutions contain ammonia, which accelerates the wear on brass. I use the Frankford Arsenal 7L Platinum Series Rotary Tumbler for brass of questionable origin. It comes with stainless steel pin media, but I just fill it with brass, soap and water and let it spin. There are specialized chemicals for tumbling, but I add two small drops of Dawn Original soap.

Be sure to dry your brass thoroughly — a single drop of water can cause a catastrophic failure. I use a Frankford Arsenal case dryer.

The best practice is to decap before doing any case cleaning or washing, which ensures the primer pocket gets cleaned also.

Now I have more brass in my garage than most gun stores have in their warehouse. I am more prolific of a recycler than any tree hugger you’ll meet. This year, my mission is to encourage more cartridge recycling activists.