SAAMI 90 Years and Counting

What Does Sporting Arms and

Ammunition Manufacturers’ Institute actually Do?

A ballistic lab loading bench looks pretty much like any home reloader’s bench.

The year 2016 marked the 90th anniversary of the Sporting Arms and Ammunition Manufacturers’ Institute, known to most shooters and reloaders simply as SAAMI. It does not surprise me while most shooters have heard of or read references to SAAMI, few understand what SAAMI does for the shooting sports. Heck, when I came on board with SAAMI as the Director of Technical Affairs I had over 40 years of experience in the industry and, as I was about to find out, a whole lot to learn about SAAMI! My trip down that path often required digging into the archives and uncovering what happened in the past to understand how SAAMI got to where we are today. As SAAMI approaches its 100th anniversary it seems like a great time to share a snapshot of SAAMI with fellow shooting and reloading enthusiasts.

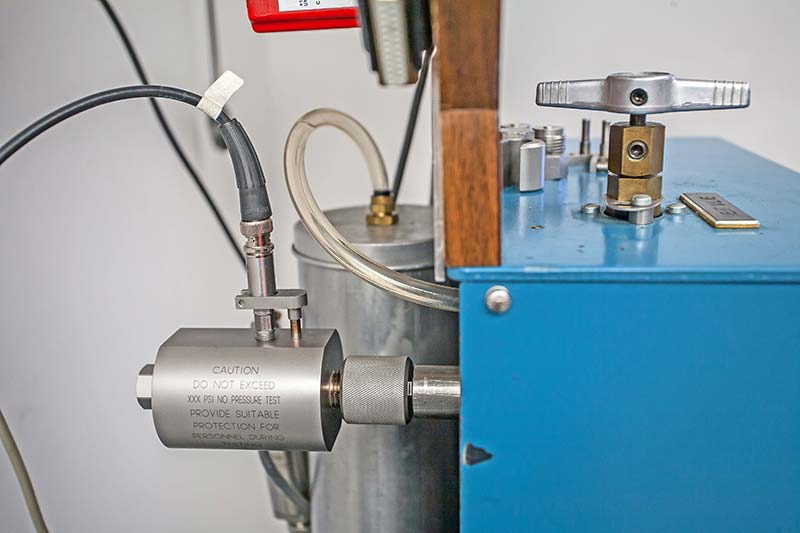

When a cartridge is fired for pressure testing the pressure reading is zero until the wall of the cartridge case comes into contact with the face of the transducer. Ever wonder about how that “lost pressure” is accounted for? An “Offset” is calculated using a high pressure hydraulic test system to determine how much pressure is required to expand the brass case to contact the transducer. The “offset” pressure reading is then added to the transducer pressure reading to calculate the total peak pressure event. The black cable is attached to the SAAMI conformal transducer.

An “offset” hydraulic cartridge case adaptor, the SAAMI conformal transducercan be seen at 12 o’clock on the top side of the adaptor.

The Nuts And Bolts

Let’s take a look into what SAAMI does and how it gets the job done. SAAMI’s mission statement headlines the Institute’s story and the work of the Joint Technical Committee: “To create and promulgate technical, performance and safety standards for, and commerce in, firearms, ammunition and components.”

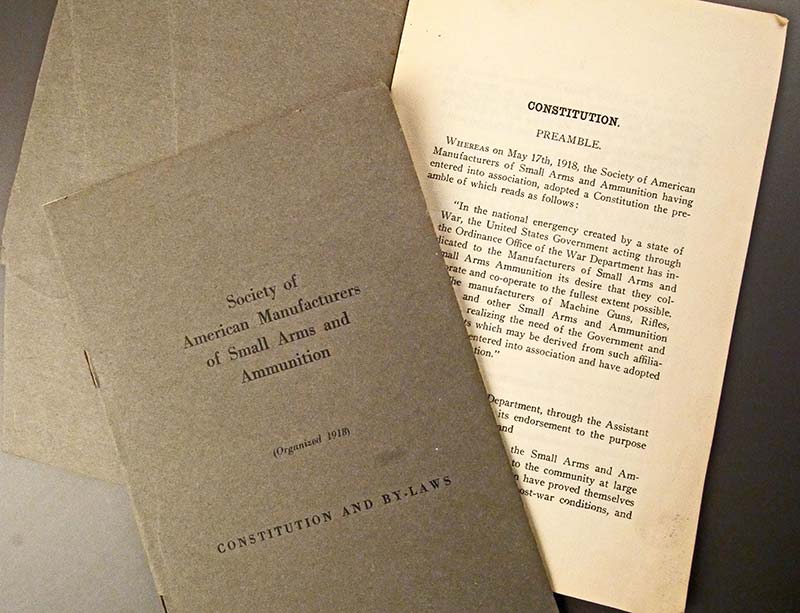

It could be said SAAMI is a child of World War I when, in 1913, the US War Department encouraged American civilian manufacturers active in the production of military arms and ammunition to establish an organization with the purpose of facilitating the exchange of new technologies and establishing common standards relative to small arms and ammunition. On May 17, 1918 at the request of the Secretary of War and Secretary of Commerce as being “worthy of continuance during post-war conditions,” the resulting organization was registered as the Society of American Manufacturers of Small Arms and Ammunition (SAMSAA). For reasons lost to time and history, the Society became inactive in the early 1920’s.

Two events taking place in the mid-1920’s would drive the move to revive the dormant SAMSAA. Smokeless powder with its vastly different performance characteristics had all but replaced black powder and semi-smokeless powder in practically all sporting ammunition. This created considerable confusion among hunters, shooters and reloaders. At the same time the US Department of Commerce was pressuring Congress to recognize that the shortage of strategic materials, brass, copper and lead created by WWI was still very much impacting many industries in the US The Congress requested the industry revitalize SAMSAA. This took place in January 1926, with the new body being incorporated as the Sporting Arms and Ammunition Manufacturers’ Institute.

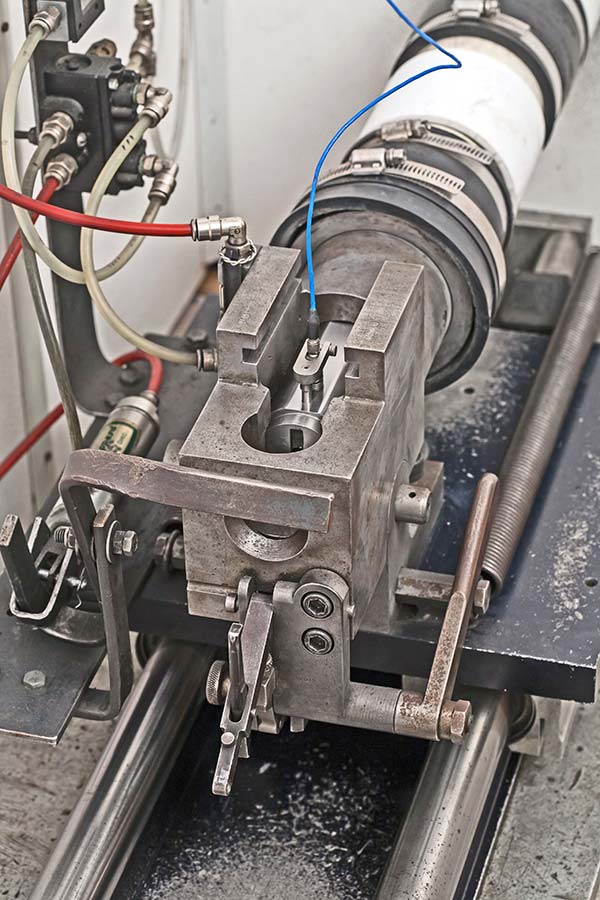

Close up of the breech end of 9mm Luger SAAMI velocity and pressure test barrel used in an universal receiver. The large hole is the conformal transducer port, the smaller hole indexes the transducer mount.

Close up of SAAMI conformal transducer ready to use in a universal receiver. The blue cable transmits the minute electrical impulse generated by the transducer quartz crystal to an instrument called a charge amplifier.

First Project

The first major project undertaken by SAAMI was a program to reduce the thousands of obsolete or near obsolete black powder and semi-smokeless powder loads for shotshell and metallic cartridges. When this program began, over 4,000 different shotshell loads and nearly 350 metallic centerfire rifle and pistol loads were available in the marketplace. SAAMI was able to reduce the number of shotshell loads on the market by 95 percent and metallic cartridge loads by 70 percent, addressing both product safety and material shortage issues.

Most sportsmen and women familiar with SAAMI consider it to be the technical arm of the firearms and ammunition manufacturing industry. However, SAAMI has a significant place in the history of wildlife management. In 1928 with market hunting and changing agricultural practices pushing wildlife populations to an all-time low SAAMI was instrumental in commissioning and financing Aldo Leupold’s monumental wildlife studies resulting in the publication of An American Game Policy and Game Management. These two books served as the blueprints for scientific-backed wildlife management. From 1931 through 1935, SAAMI financially supported the Clinton Game School in New Jersey, graduating 145 of the first technically trained wildlife management employees of federal and state fish and game departments.

Beginning in 1933, the gun industry had been subjected to a 10 percent federal excise tax, a levy that evoked no cheers from the gunmakers or anyone else as the original excise tax on firearms was channeled directly into the general fund and none of it was spent for wildlife restoration purposes. In 1937, the Pittman-Robertson Federal Aid in The Wildlife Restoration Act was passed, providing that the federal excise tax on sporting arms and ammunition be earmarked for wildlife restoration. SAAMI’s executive committee, through the efforts of John Olin of Western-Winchester, was instrumental in gaining industry’s full support of the proposed new program and incorporating the findings of Aldo Leopold’s wildlife survey.

Old school! The barrel set up in this universal receiver fitted for copper crusher pressure (C.U.P.) testing. Notice the copper colored rod sandwiched between the piston head on the top of the barrel chamber and the retainer bolted to the universal receiver.

Overview of a universal receiver minus a barrel. When the barrel is mounted it would extend into the tube forward of the universal receiver.

Velocity and pressure testing with a universal receiver is arduous at best and when it only gets worse when developing velocity and pressure data for muzzleloading firearms. Here a universal receiver has been mounted on a track to facilitate loading from the muzzle.

At an average cost of over $1,500 per test barrel, a fully equipped ballistic lab has a sizable investment in SAAMI Velocity and Pressure test barrels.

Today’s Work

When asked by people in the industry and shooters and hunters what it is SAAMI does my answer is SAAMI’s core mission is developing and maintaining technical and safety standards for the design and manufacture of sporting arms and ammunition. Many would envision the SAAMI facility located in Newtown, CT to be an enclave of ballistic laboratories, shoot tubes and R&D machine shops staffed with engineers, technicians, machinists and support staff.

In reality SAAMI’s mission is delivered by a very small professional staff of four who manage the daily affairs of the institute and coordinate the activities of a number of strategic committees, the principal committee being the Joint Technical Committee (JTC). The JTC is comprised of technical representatives from the 31 SAAMI member companies that hold voting status. The JTC meets every January and June.

The JTC is comprised of three sections: firearms, ammunition and muzzleloading. While each section is tasked with overseeing the proposal and ongoing maintenance of standards relative to their manufacturing sector, the Joint Technical Committee brings all the sections together to discuss technical issues affecting multiple sections, such as a new cartridge and chamber design introduction. It is essential both the ammunition and firearms sections review and approve the design and operating characteristics to ensure the functional safety of the new design from both the perspective of the ammunition and the intended firearms.

I am often asked to draw a comparison between SAAMI and our European standards counterpart, the Commission Internationale Permanente (C.I.P.). SAAMI is an accredited standards developer to the American National Standards Institute (ANSI) and ANSI is the sole American representative, and founding member, of the International Origination of Standards, commonly known as ISO. ISO’s mission is to promote the development of standardization and related activities in a global marketplace.

SAAMI sponsors five American National Standards which were developed by Product Standards Task Forces of the SAAMI Joint Technical Committee. The five standards set forth dimensional and performance criteria and recommended testing processes and procedures for ammunition or firearms. Each standard is subject to approval by canvassing and the consensus vote of materially interested parties representing product end users, government agencies and departments, independent materials testing laboratories, non-SAAMI member companies, independent consultants and experts in the field. Upon canvass approval, the standard is submitted for affirmation by the ANSI Board of Standards Review. The ANSI SAAMI standards are continually reviewed and updated at least every five years to reflect current practices and emerging technologies.

While SAAMI was created at the request of Congress, no provision was made to fund the organization through the federal government. All SAAMI’s research, standard development and maintenance, and programs are funded by membership dues of the member companies.

The SAMSAA Constitution. SAAMI’s lineage dates back to the World War I era and the Society of American Manufacturers of Small Arms and Ammunition.

The C.I.P.

In 1914 European governments established by treaty an association, the Commission Internationale Permanente (C.I.P.), which prescribes the loads, methods and procedures by which firearms and ammunition are tested for safety. Proofing of firearms and homologation of ammunition is done at regional Proof Houses established by the government for that purpose. Funding of C.I.P. activities is largely through member government funding and to a lesser extent by funds generated by commercial activities of the individual Proof Houses.

While both organizations have similar goals — creation and maintenance of standards that insure the safety, function, and performance of firearms and ammunition — how the two programs are delivered is very different.

ANSI SAAMI standards are voluntary compliance while C.I.P. standards are the letter of the law. Often great emphasis is made of the fact C.I.P. standards are enforced by law and SAAMI standards are not. My response is while C.I.P. bears the weight of the law; SAAMI voluntary compliance bears the impact of a potential product liability suit due to non-conformance to an accepted industry standard. The fear of a liability suit can be as or even more of a compelling reason for voluntary compliance than the law. Since 1972 the American firearm and ammunition industries have enjoyed freedom from control by the federal Consumer Product Safety Commission, a privilege the ammunition and firearm industries do not take lightly.

Continual improvement and updating of the ANSI/SAAMI standards is essential to maintaining SAAMI’s worldwide status as a recognized authority in the field of ammunition and firearm manufacture and testing. ANSI/SAAMI standards are the heart of significant cooperative relations between SAAMI and many federal and state agencies that reference or use the ANSI/SAAMI standards.

Through collaborative efforts, C.I.P. and SAAMI are working towards the development of internationally recognized standards. SAAMI and C.I.P. work cooperatively to ensure technical data for all new cartridge and chamber designs submitted to either entity is shared to ensure interchangeability, safety and satisfactory performance. In addition, SAAMI and C.I.P. are working closely to coordinate their pressure-testing programs.

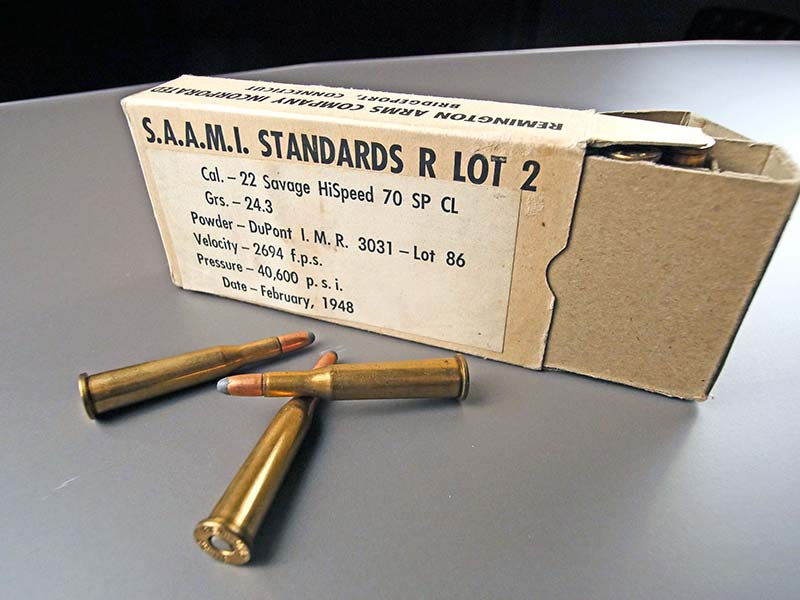

A Vintage Ref Ammo Box. Special “reference ammunition” has been a major part of the SAAMI standards to qualify ballistic laboratory test equipment and process for over 70 years.

A universal test receiver setup with a 12-gauge barrel, fitted with a piezoelectric quartz pressure transducer to capture chamber pressure and velocity data. Photo: PCB Piezotronics, Inc.

Other Committees

While the technical standards are the core of SAAMI’s mission and of most interest to shooters, we would be remiss if we did not take a moment to look into the work of the other committees that have, or still do, function under SAAMI’s umbrella. Suffice to say, committees such as Legal and Legislative Affairs, the SAAMI Logistics and Regulatory Affairs Committee, the International and United Nations Committees have an equally long record of significant contributions to the joint interests of the SAAMI membership.

The Legal and Legislative Affairs Committee is responsible for tracking developments at the state and federal level in the field of product liability law and legislation that impact the design, manufacture and sale of firearms, ammunition and propellants by SAAMI member companies.

The SAAMI Logistics and Regulatory Affairs Committee works to shape the constantly evolving transportation and storage regulations, both international and domestic, so SAAMI products can be distributed economically, securely and safely throughout the world. SLARAC’s direct involvement in developing the ORM-D, now referred to as LQ “limited quantity,” exemption for sporting ammunition, propellant powders and primers saves the shooter an estimated $4,000,000 a year in transportation charges.

SAAMI has over the years been very involved in addressing international treaties and accords that will adversely affect shooter and firearms and ammunition industry worldwide. SAAMI is an accredited United Nations ECOSOC Non-Government Organization (NGO) with Consultative Status. For the last 25 years SAAMI has provided the UN with technical information related to SAAMI-member company products. The issues facing the UN are daunting and complex.

For nearly 100 years, SAAMI has been committed to the safety and performance of the ammunition and firearms available to the American shooter. Be assured the SAAMI Board of Directors, staff and committee members are committed to continuing that dedication to shooters over the next 100 years!

Author Bio:

Randy Bimson’s career spans 48 years in the firearms industry. He is an accredited design engineer, journeyman gunmaker, expert witness regarding firearms and ammunition, a former columnist for Shooting Times Magazine, and has made significant contributions to the publication of Brownells, Inc. Gunsmithing Kinks and VSP Publications The Ruger Single Action Revolvers, A Shop Manual, Vol. I & II. He held the position of Manager, Technical Service and Factory OEM Parts with Brownells, Inc. and Technical Support Manager/Senior Technical Advisor with Beretta USA. In 2011, he was appointed the Director of Technical Affairs and Technical Advisor at the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI). An ardent big game and upland bird hunter, Bimson has hunted extensively on four continents. A certified firearm safety master instructor for rifle, pistol and shotgun, he is an accomplished competitive rifle and handgun shooter who wishes his ability to wingshoot equaled his appreciation for fine shotguns!

All images are courtesy of Sporting Arms and Ammunition Manufacturers’ Institute, Inc. in cooperation with the Hodgdon Powder Company.