A Worthy Nod to the Famous #5

The Tyler Gun Works #6

Tyler Gun Works completed a custom sixgun that’ll surely rock sixgunners’ worlds far and wide. Head honcho and owner Bobby Tyler wanted to build a one-of-a-kind gun exhibiting the skills his staff is capable of in a vintage, “old-timey” style, using age-old techniques of yesteryear while implementing the use of modern machinery and tooling. This is a story about making the highest-grade Colt Single-Action Army — the best the Tyler shop has ever produced.

The Story

Tyler wanted to push his staff to their outer limits to see what they were capable of designing. What they came up with, many will consider “the Holy Grail” amongst sixgunners.

Led by the coolest name in sixgun smithery, Dusty Hooley, the shop succeeded. Much like Rigby and Holland & Holland did during the turn of the century when producing their finest arms and calling them “best quality.” This is definitely a TGW “best quality” arm.

Second, Tyler wanted a gun capable of inspiring all who held it, filling them with curiosity while making them wonder about the history and background of custom sixguns and how they came to be. The gun would pique the interest of aspiring sixgunners not knowing names like Keith, or Croft. The gun would need to be worthy of making the holder say, “Wow!” whenever seeing or holding it.

Sure, good gunsmiths can make fancy guns, but this gun would have a purpose! A lofty goal, if ever there was one, but one which the Tyler crew accomplished in aces.

Looking Back

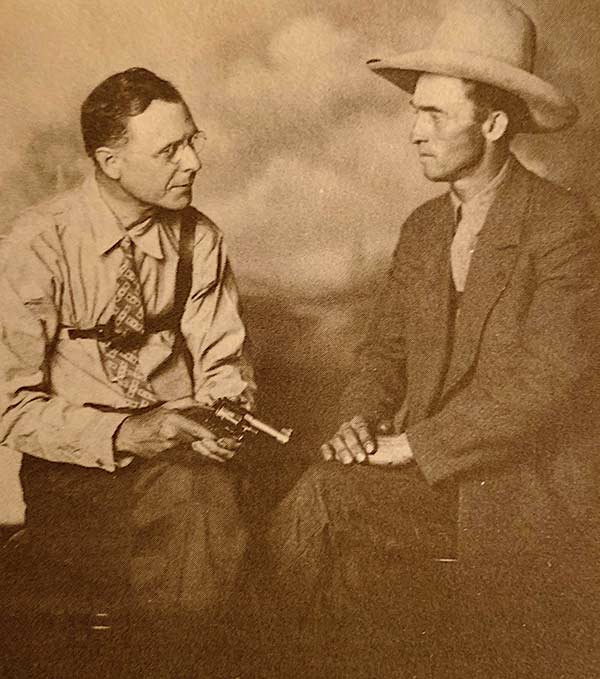

After a week of traveling by train, the weary Philadelphian was tired and hungry, yet excited. Getting his luggage, he spots a smallish man wearing a wide-brimmed cowboy hat sitting in a buckboard wagon from the platform.

The cowboy squints, waving him over, “Croft, is that you?” Relieved, Croft answers in the affirmative. The cowboy extends his hand, telling him to throw his luggage in the back, as Croft shakes the cowboy’s gnarly, callused hand. “Elmer Keith, pleased to meet you,” says the cowboy. The four-hour wagon ride to Keith’s two-room cabin jostles Croft awake as he and Elmer talk guns during the ride.

This scenario illustrates the time frame when this meeting occurred. Even though the technology of the day was far from today’s standards, custom gun work was well ahead of the curve, as you shall see.

History

Back in 1927, while writing for American Rifleman, Keith talks of long-range sixgunning at distances many thought preposterous. Intrigued by Elmer’s claims, Harold Croft, a fellow sixgun enthusiast from Philadelphia, Pa., exchanges letters with Elmer. Elmer invites Croft to his Durkee, Ore., ranch for a month. I’m sure Croft was doubtful of Elmer’s long-range claims. Many were.

Croft accepts, bringing a “suitcase full of guns,” as Elmer describes it. Upon Croft’s arrival, Elmer nails boards together, making a 4’x4′ target, setting it a measured 700 yards away. Using his sitting “Keith” position, with hands locked between his knees, head resting on his saddle, Elmer shoots, hitting the target with every gun Croft brought. Croft is a true believer.

Croft brought what he called four “featherweight” custom revolvers built on Colt single-actions in .45 Colt: two SAAs and two Bisleys, numbering them #1 through #4.

Elmer penned, “My good friend S.H. Croft put in a lot of time, thought, and money improving the SA Colt. He was working to obtain a lightweight weapon for self-defense purposes. Mr. Croft had four models of featherweight made up from SA Colts.” Croft introduced Elmer to work performed by J.D. O’Meara, R.F. Sedgely and Neil Houchins with these guns.

Elmer sends Croft home with an SA Colt with instructions on what he wants done to it. Hence, the Keith #5 was born, and Elmer writes about it as being the ultimate sixgun in his eyes, writing “The Last Word” describing the gun and its merits in the April 1929 issue of American Rifleman.

TGW #6

A gun of this magnitude is worthy of capturing the moniker #6. I think it perfect, appropriate even, given the purpose and intent of this gun by its maker. Following in the footsteps of some of the greatest sixgun men in history and wanting to revive interest in custom guns, the name itself provides curiosity to the unknowing. For those in the know, it provides excitement.

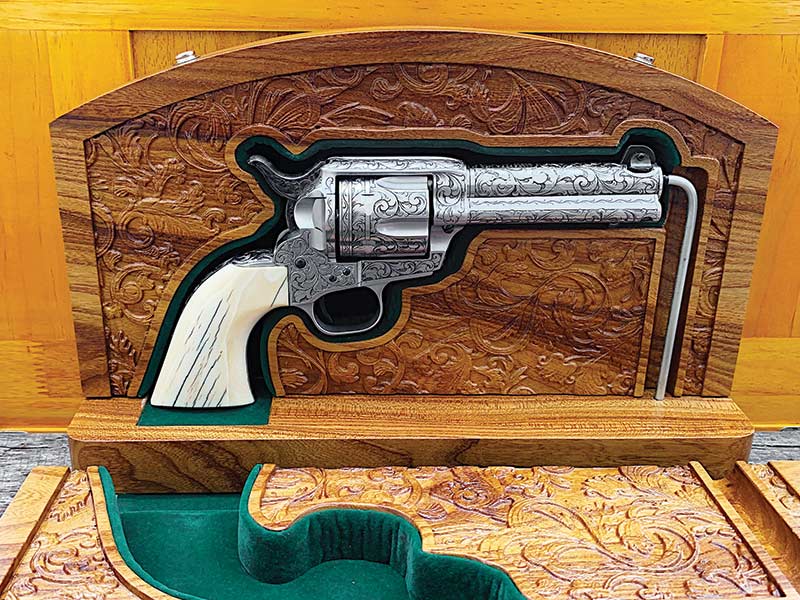

The base gun for the #6 started as a second-generation Colt SAA. It left the Colt factory as a nickeled 4¾” .45 Colt. It was stripped down to the frame and accompanied with a bag of various parts, minus the barrel. Dusty remedied this by using a Douglas barrel blank, threading, fitting and dovetailing it.

Details

While the frame itself was in excellent condition, the nickel finish was rough. Hooley relief cut the recoil shield, including the loading gate and cylinder frame, in front of the trigger guard, in a “Croft manner.” These cuts stylishly lighten the gun.

Dusty then fit a USFA grip frame to the cylinder frame after drilling a series of holes in it to lighten it. The hammer is beautifully engraved and color-cased. Screws are also engraved, with slots timed to the same orientation. The screws, ejector rod button, trigger and Keith #5 base-pin are niter blued, contrasting beautifully with the engraving.

A TGW Exclusive Custom Adjustable Dovetailed Front Sight, with a serrated blade, was used for the front sight. The sights are made by Ronnie Wells. Hooley hand-fit and timed all working parts to perfection, giving the gun the smoothest action and tightest cylinder lock-up you’ve ever felt. It is the standard TGW action job. The barrel/cylinder gap was set at a tight 0.004″. Trigger pull is a crisp 2 lbs., 4 oz.

Sharp Scratches

Rocky Sharp invested over 60 hours of skilled labor, providing the gun with full coverage engraving to complete the job. The artwork was hand-drawn and hand-cut without the use of a pattern. The entire gun was then hard chromed to perfection, as re-nickeling a gun is a chancy proposition.

As a final act of accessorizing, Hooley fitted classic one-piece white ivory stocks to the grip frame, nobly accenting the gun perfectly.

Vintage Box

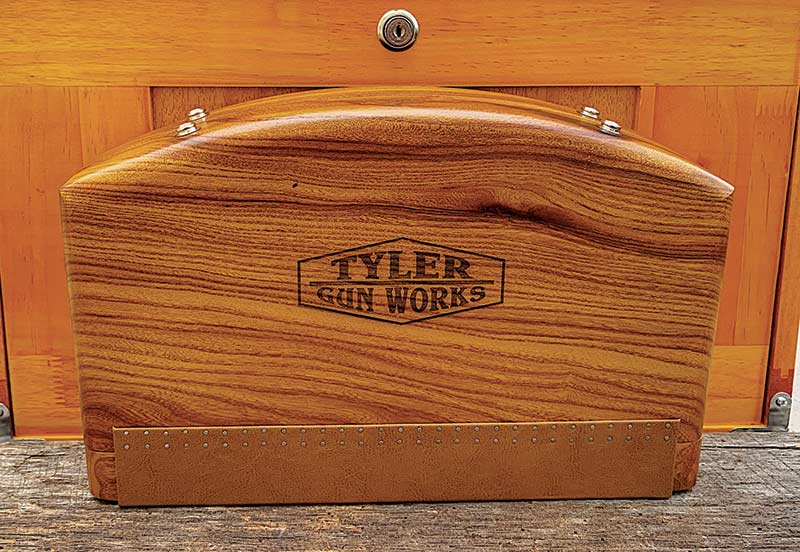

The #6 is housed in an oak bi-fold box with a leather hinge, giving it the appearance of something a turn-of-the-century salesman would carry, and one that Harold Croft might have used when visiting Elmer, although not as ornate.

Upon opening the box, the interior explodes in highly carved wood. Recessed halves safely cradle the gun in green felt lining. A coated steel rod holding the gun keeps it secure when both halves are dropped.

Bobby had Glenn Dean of Classic Chests build the exquisite box. Bobby believes him to be the best in his field now and used him for the “Cattle Brand” 1911s from last year. Tyler was striving for a small and delicate-looking box blasting with beauty upon opening while showcasing the gun at the same time.

Leather

Bobby used “Doc” Barranti, of Barranti Leather, now of Dunn, Texas, to fill his holster needs for the #6. Doc built a minimalist custom patterned Three Persons style holster from his Barranti/Myres custom line using a traditional Myres carving pattern for the #6. After all, a custom lightweight gun deserves a custom lightweight holster. The holster has a natural oiled finish and fits the #6 beautifully.

Shooting

Yes, I actually shot this piece of working art at Bobby’s insistence. Bobby laughed when I told him I was scared just picking it up. The gun shoots as good as it looks. I had a box of Black Hills cowboy loads on hand, along with some Federal loads. Shooting was at 25 yards, rested. The gun and loads routinely shot 1–1.5″groups.

Final Word

The #6 is intended to be a piece of working art, pleasing to the eye while inducing vigorous thought about past and present gun building. By using master craftsmen in their chosen fields, you can’t help ending up with a top product. This is where TGW excels.

Bobby Tyler sums it up nicely, “It’s important we remember where we came from, not that we want to go back, but if we can’t learn from yesterday’s craftsmen, we will never be craftsmen of the future.

“Holding traditions together while building custom revolvers is not a job, but a passion. We have minimized our backlog and opened our books back up for custom gun builds. It looks like 2024 will be the year for Custom Revolvers at Tyler Gun Works!”

If you’re looking to have a custom sixgun built with the same blueprint from past historical guns, with the advantages of modern technology, give Tyler Gun Works a shout. Having a vintage style gun with purpose, one having background and history, will please you in more ways than you’ll ever know. Who knows, you just might end up with your own #7.