Re-Born Re-Volver

The revolver had been gathering dust on the display shelf, unwanted and unappreciated. It was one of a group of police trade-ins purchased by my local gun shop, the Sportsman’s Loft. It was a S&W Model 13 .357 with 3″ barrel and round butt. The 13 and its stainless steel version, Model 65, appeared some 40 years ago. They served a generation of plainclothes law enforcement officers, and were the choice of agencies such as the FBI.

They were replaced not by better revolvers, but by auto pistols. The 13/65 revolvers were the last of their type, and arguably the best — elegantly simple, reliable, an ideal balance of size, weight, accuracy, controllable recoil and power.

So, why was this example languishing on the shelf? It looked terrible, with worn finish, surface rust, even some pitting. Most potential buyers took one look, shuddered and moved on to something prettier. I was about to do the same when I noticed the side plate screws were in perfect condition. Whatever else it had suffered, at least no one had attacked it with an ill-fitting screwdriver.

When Chris handed it to me, inspection showed the chambers and bore were immaculate, with not a trace of rust or pitting. The holes in the frame for the firing pin and cylinder-locking bolt were unworn and perfectly round. The cylinder stop notches showed no indication of peening. There was no indication of flame cutting. With the cylinder closed there was barely detectable rotational play and no perceptible fore-and-aft play. Both single and double action, the cylinder carried up properly. I was holding a practically new revolver; it was just uglier than a flat tire in a mud hole. I told Chris to start the paperwork.

Robarizing

Initially, the plan was to ship it to S&W for refinishing. A trip to the range altered my plans. It shot .357 Magnum Black Hills 125-gr. JHPs (at a chronographed 1,350 fps) into 2″ groups almost exactly to point of aim at 25 yards. It balanced and handled beautifully. For a bit over $300 with tax, it was close to an ideal carry gun. All it needed was a tough, rust-resistant finish. I rethought about it all.

Robar Industries specializes in metal finishes. Many Robar customers make medical, automotive and aeronautical products and Robar uses their space-age finishing ability to coat their products with a variety of finishes. Robar owner Robbie Barkmann mentioned recently that firearms work is about 11 percent of the business. It’s an important 11 percent, though, because Robbie is one of a shooter, an enthusiast and us. When he emigrated here from South Africa long ago, it was as one of the first instructors working with Jeff Cooper at the new Gunsite facility. Robbie knows guns and he can really shoot.

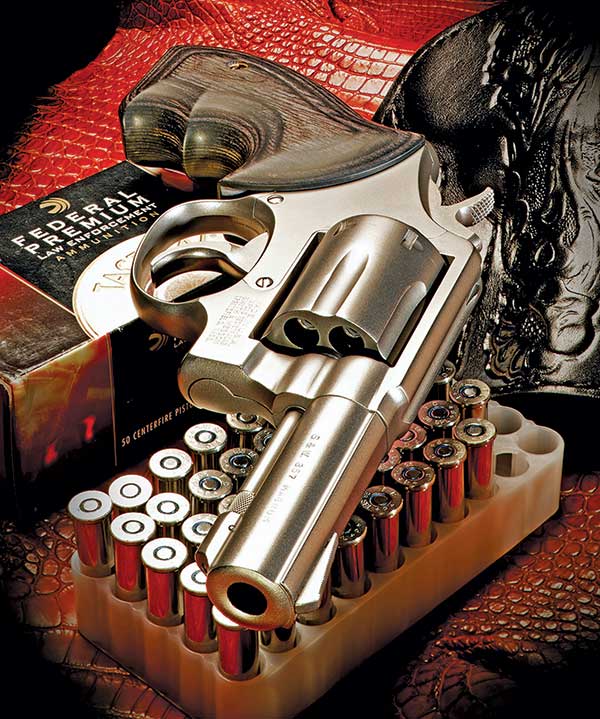

Robar offers several finishes, of which my favorite is NP3. This ingenious finish combines electroless nickel with a slippery compound called PTFE, commercially known by the trademark Teflon. It is tough, rust-resistant, provides natural lubricity, cleans up easily and looks good. I requested a recent variation called NP3 Plus, providing increased rust resistance.

Robar also provides a wide range of firearm services, such as sight installation, frame stippling, fitting match barrels and full-house handgun, rifle and shotgun packages. For a modest additional charge ($85/hour, and they do a lot in an hour) Robar can polish a worn-looking gun. They can’t accomplish miracles, and a really neglected gun may have rust pits too deep to polish out. On my gun the transformation was absolutely astounding. I could hardly believe it was the same revolver.

A Tidy Package

The revolver really needed high quality accessories to match the Robar workmanship. I ordered a set of his frame-length Boot Grips from Kim Ahrends. From the wood page I selected the silver-black “Dymondwood” laminate to go with the new finish. The grips proved to be exactly what I wanted. They fit the frame perfectly, provide a secure and comfortable hold, conceal well under a light jacket and look terrific. Ahrends is well known for his superb line of 1911-style grips. S&W fans should know of his excellent revolver grips, both the Tactical and Retro lines. Ahrends provides many wood choices and truly exceptional workmanship.

The work of Jerry Evans of Haugen Handgun Leather is no stranger to Handgunner’s pages. Jerry supplied a pancake-style concealment holster in black leather, with lining, adding a thumb break and an embossed floral pattern. It’s beautifully made and very comfortable.

Robbie’s before and after photos show the transformation better than any words. The slick NP3 Plus finish on internal parts makes an already good action even smoother. The smooth finish makes cleaning a breeze too.

Clint Smith is fond of saying: “Wheelguns are real guns.” He’s right, you know.

Get More Revolver Content Every Week!

Sign up for the Wheelgun Wednesday newsletter here: