What’s A Locked Breech

Blowback semi autos work fine with cartridges of moderate power such as .22 LR and the .25, .32 and .380 ACP. For use with more powerful cartridges, designers had to find a way to keep the action locked until pressure had dropped. Quite a few solutions have been developed, some of which have proved more practical and successful than others. The tilting-barrel system designed by John Browning wasn’t the first, but for over a century has proven to be the most widely used.

It’s a cliché to say John Browning was a genius. Actually it almost seems too weak a word. I believe it was Jeff Cooper who once said even the word genius doesn’t do justice to Browning — he was a magician. The more you study the development of firearms, the more you will stand in awe of Browning.

The 1911 design wasn’t the first locked breech semi auto or even the first with the tilt-lock, but it’s certainly the best known, having been in continuous production for over a century.

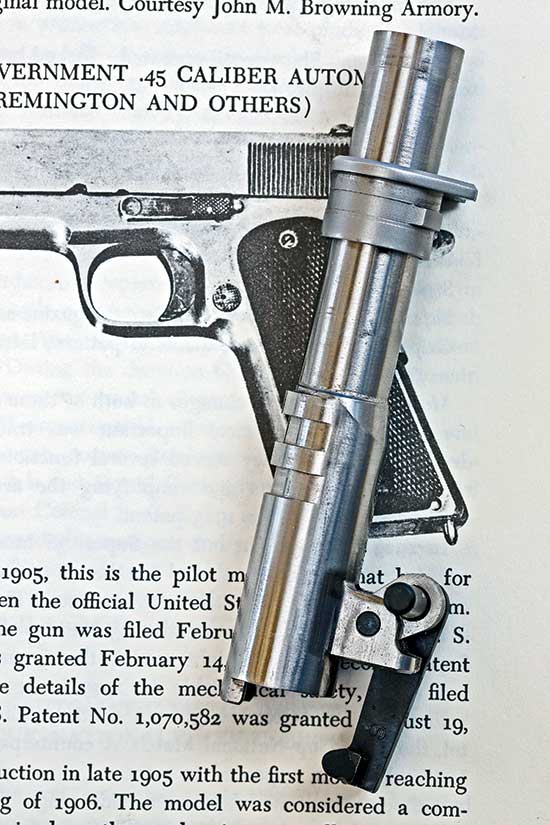

The barrel has two lugs on top, just ahead of the chamber. The slide has two matching recesses into which these lugs fit when the slide is in battery. On the bottom of the barrel is another lug with a curved surface riding on a cross pin (which also serves as the “axle” for the slide lock) in the receiver, pushing the barrel up into the locked position. A link connects this bottom lug to the cross pin.

The Locking Magic

When a shot is fired, just as with a blowback, gas pressure accelerates the bullet in one direction, the slide in the opposite direction. Since the slide is much heavier than the bullet it accelerates much more slowly. But unlike the blowback design, the barrel is moving with the slide, the two components locked together. The cartridge case is still supported by the steel of the chamber and is still sealing off powder gases.

After the slide has moved about 1/10″, the link connecting barrel lug and slide lock pin stops the barrel from moving further rearward and pulls the barrel locking lugs out of the slide recesses. The momentum of the slide keeps it moving back, extracting and ejecting the fired case, compressing the recoil spring and cocking the hammer.

In a blowback pistol residual gas pressure extracts the fired case, and the mechanical extractor serves only to remove unfired cartridges. With the 1911 locked breech design there is little residual gas pressure, generally not enough to extract and eject the case. The pistol’s extractor is a vital component. If it breaks or loses spring tension the pistol will not function reliably, if at all. Checking the extractor is simply part of the maintenance routine with a locked breech semiautomatic.

In the 1911 design the front of the barrel is held by a bushing fitted into the front of the slide. In order for the barrel to tilt the fit cannot be too tight. On the other hand if the fit is too loose, accuracy will suffer.

There have been many variations on the tilt-lock system, generally with the objective of simplifying the design and making manufacture easier and simpler. One of the first variations was designed by Browning.

Hi-Power

The Browning Hi-Power uses two locking lugs on top of the barrel, as with the 1911. Instead of a link on the bottom lug, the lug is made with a cam, which rides the slide stop pin to control locking and unlocking. At the muzzle end, the barrel simply fits the front of the slide with no separate barrel bushing.

Another variation is an enclosed track in the bottom lug, as on the CZ-75 and several others. A very popular variation in today’s designs is to dispense with the locking lugs on the barrel, and locking lug recesses in the slide. Instead, the chamber area of the barrel is squared off, with a lip on the top edge of the chamber engaging the front surface of the ejection port.

With all of these designs the locking surfaces are under high pressure as unlocking occurs. Keeping the locking surfaces well lubed with oil or grease reduces wear on these parts and enhances reliability.