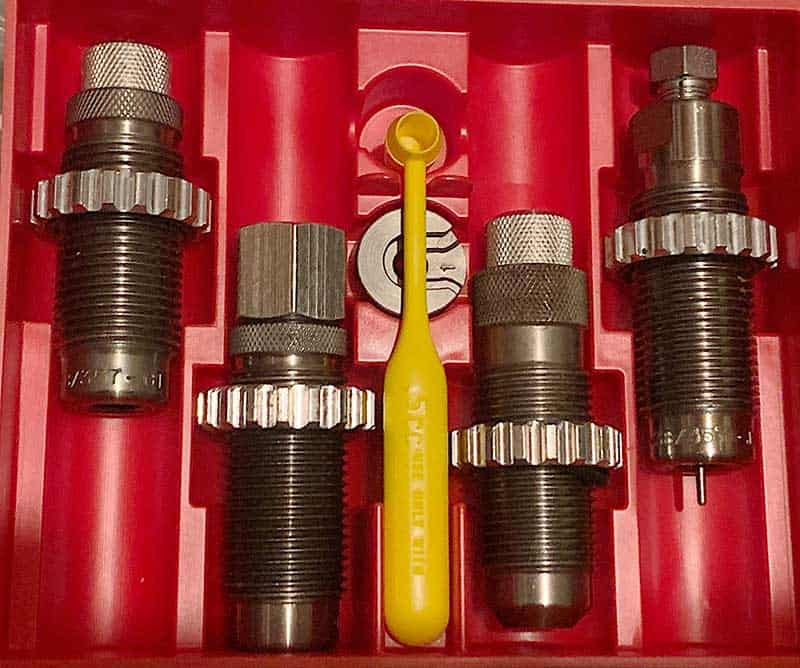

Setting Up Your LEE Deluxe Pistol Dies

Make no qualms about it, I love LEE dies! Who wouldn’t? They’re priced competitively, they load accurate ammunition, and they even come with a shell holder, powder dipper and load data. Over 90% of my dies are from LEE. The other 10% are a cross-section of what’s available from all the major manufacturers because either LEE didn’t make dies in the caliber I wanted, or I wanted to try others for comparison’s sake.

Setting Up Your Dies

Roughly 80% of my handloading is done on my LEE classic turret press. I can swap out calibers and primer size feed in all of 10 seconds. It’s that easy. For massive bulk reloading, my Dillon 550C gets the nod, but it’s easier and faster to use the classic turret press for different powders and charge weights during load development.

The turret press uses aluminum die plates with four holes for up to four different dies. If you buy numerous die plates, which I do for each set of dies, setting your dies up is a one-time proposition. It’s too convenient not to store your pre-set dies in the die plate. They store neatly in the round LEE die container too.

Carbide Sizing/Depriming Die

The first die in the sequence of reloading is the carbide sizing/depriming die. This is an easy one. Simply pull your loading press handle down until the ram is in the upper most position. Now screw your sizing/deprimer die until the bottom contacts the shell holder. Tighten the lock ring of die to bottom of the die plate. You’re done! With a carbide liner, there’s no need for case lube on straight-walled cases.

Flare/Charging Die

The second stage is the flare/charging die. Start with your sized/primed brass in the uppermost extended position in the ram. Screw the flare/charging die down until it contacts the case mouth. Lower the press ram a little and screw the die in a quarter turn. Extend ram and then lower it, checking the amount of flare in the case mouth.

Repeat as needed until you are satisfied you have enough flare, but not too much. When satisfied, extend ram. This will lock the die so you can tighten the die lock ring, keeping it in place for future use. You can charge the case now with the dipper and funnel or use LEE’s powder disc system which screws into the flare/charging die after removing the top nut of the die.

Lowering the ram primes your brass. As you raise it again, your die plate progresses

to the next station. Screw in the expanding die until it contacts the mouth of your brass.

Lower ram slightly and turn die ¼ turn clockwise, then raise the ram to the upmost position.

Repeat until you’re satisfied with the amount of flare in the case mouth. Tighten die lock ring.

Bullet Seating Die

The easiest way to set your seating die is to simply use a piece of empty brass and run the ram up to the top position. Screw your seating/crimp die down until it contacts your brass. Now start turning the die clockwise in ¼ turn increments, checking the crimp with each turn. When you’re satisfied with the crimp, the next step is to set the seating stem depth.

I start by screwing my seating stem almost all the way down. Add your bullet to your primed/charged/flared case and slowly start seating your bullet. Check bullet depth frequently until the top of the case mouth is flush with the crimp groove of the bullet. Raise your seating depth stem almost to the top and run your cartridge to the top, crimping your brass. Lower the seating stem until it contacts the top of your bullet and you’re done!

Run an empty case to the upmost position and screw in the seating die until

contact is made. Tighten die until you’re satisfied by the amount of crimp. Turn

the die stem down to the lowest position. Now add your charged brass case to the

shell holder and place bullet in the brass. Slowly raise the ram until the bullet is seated

to bullet crimp. Raise the seating stem and crimp case, then lower the seating stem

until it contacts bullet. Your die is adjusted.

Carbide Factory Crimp Die

Screw the LEE factory crimp die in until it touches the shell holder, then back out the adjustment stem. With a loaded round in the die, screw the adjustment stem in until it contacts the case mouth. Move the cartridge out and tighten the stem ½ turn for light crimp and one full turn for heavy crimp. There’s no fear of case buckling during heavy crimping with the factory crimp die. The carbide sizer also ensures your cartridge is within spec for problem-free chambering in your gun.

Classic Reloading

Using the classic turret press with the LEE deluxe dies is a great system. I can reload 50 cases in a leisurely 15 minutes with the auto disc system and safety prime. If you reload a lot of different calibers, the classic turret press is a good way to go.