Yesterday, I cast just over 400 bullets from a favored Saeco 411 230-grain Keith mold. In just over an hour’s time, I cast, tumbled them in Powder Coat (PC) and baked them for 20 minutes at 400 degrees. In just that hour, I had more bullets to load — for the next day’s shooting. I tell you this not to brag, but to explain why I cast my own. Sure, I could have ordered them, and waited a few days for the brown truck to deliver them, but I hate to wait, and I hate to pay for bullets!

When you make your own bullets, you have more control over any one aspect to handloading there is. You get to determine what shape, size, style and hardness you will cast. Nothing beats the smug feeling of christening a vintage mold by casting with it to unlock the secret of breathing life into an old favored shooter of some defunct caliber using handloads. True Keith SWC’s, LBT styled radiused-flatnosed bullets designed by Veral Smith, gas checked SWC’s developed by Ray Thompson, or Hollow Point bullets that literally turn themselves inside out when they hit something are just a few options available when you pour your own slugs.

Cast Bullets Simplified

For about the price of three boxes of loaded ammunition, you can buy yourself a good mold. While the three boxes will be long shot up, a good mold will last generations. With this mold in your possession, you have the key to making bullets whenever needed, along with a lifetime supply of them. Bullet hardness can be adjusted by type of alloy used and heat-treating methods depending on the use and purpose the bullet is used for.

Need a lot of bullets in a hurry for an upcoming competition? Get yourself a 6-cavity mold to shuck bullets faster than your alloy pot can keep up. Hunting large, heavily muscled big game? An LBT radiused flat nose is just the ticket for a deep, penetrating, permanent wound channel. Want jacketed bullet-like expansion from a bullet you made yourself? A MIHA custom hollow point will plop out those pills with ease.

It’s Technique

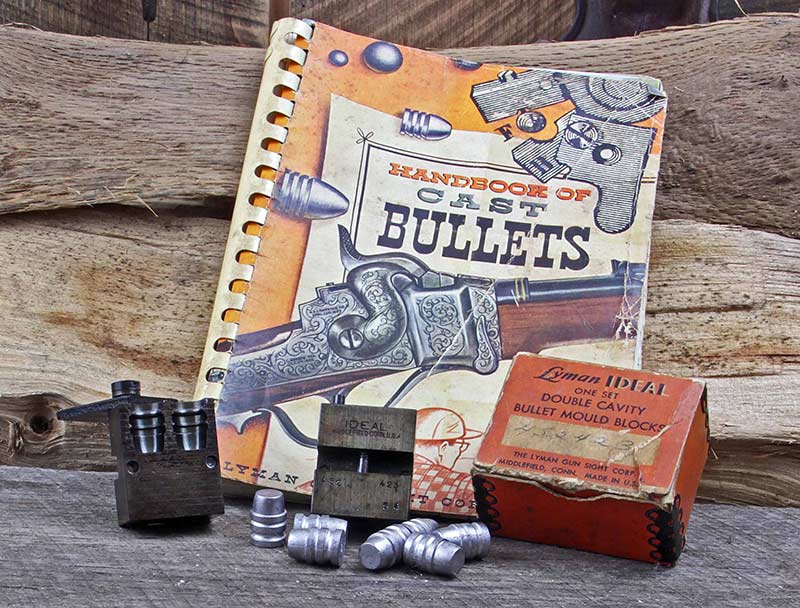

Be they polished brass, blued steel, or light aluminum with the proper technique, all molds can cast beautiful bullets. Lineage has no bearing either.cLyman, Lee, RCBS, Saeco, or custom blocks from LBT, Miha, or others, they all offer great options to fill any niche that needs to be scratched. Don’t be a mold snob. Some of my least expensive molds cast the most accurate bullets for some guns. Over time, you will accrue a nice collection of molds.

Want to try a certain bullet style without committing to purchasing the mold. Go to one of the many cast bullet sites. Someone will happily sell, or give you some free samples for the measly cost of postage. Some of the commercial cast bullet outfits sell bullets from common mold manufacturers. It’s all just a few clicks away.

Collecting alloy can be both challenging and interesting. The humble Wheelweight (WW) made of lead, antimony, a smidge of tin, and a pinch of arsenic are about the best and most versatile alloy. Common, their air-cooled hardness is about a 10 BHN and they can be oven heat treated to a hardness of over 30 BHN. Dropping hot bullets from freshly cast slugs into a bucket of water will quench your cast projectiles anywhere from 16-22 BHN. Lead roof flashing, pipe, lead shot and plumber’s lead are other sources. Some people are allowed to mine for lead at their local range berm. Get friendly with your local gas station. A bottle or 6-pack of a favorite libation can go a long way for free lead.

Embrace your new found independence and self sufficiency of casting your own bullets and take pride in punching holes in paper or critter, made by your own hand. The convenience of casting ones bullets will give you independence as never before when you have a good supply of lead and some good molds.