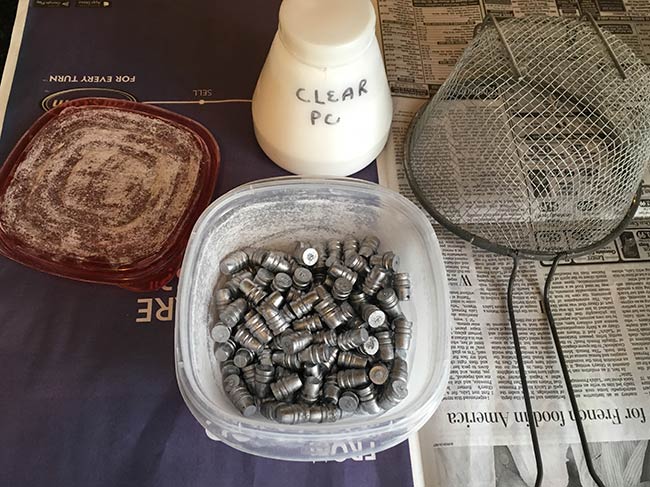

2: The bullets I’m doing today are from a favorite Lyman 454424 bullet mold and I’m doing about 100 bullets for this demonstration. Sprinkle about ½ teaspoon of PC on your bullets and snap your lid on. Now you shake, rotate or swirl your bullets for about 30 seconds.

I’m using a clear PC I ordered from “Smoke” on the CastBoolits.gunloads.com forum. I believe its Eastwood PC, but am not sure. He sells it by the pound for around $12, but it’s worth it. I also use Harbor Freight with good results, but it just takes a little more effort to shake and coat the bullets.

Once your bullets are coated like the picture, dump them in a coarse screen strainer, or some tightly woven chicken wire, and shake off the excess powder. This is a key step to keep your bullets from becoming a “melted blob” of bullets. The excess PC melts, making a terrible mess.

Tank’s Powder Coated Cast Bullet Clinic

By now, you’ve observed my proclivity for Powder Coated (PC) projectiles I’ve cast myself. In 30 years of casting, I’ve come to the conclusion PC cast slugs is faster and easier than traditional lube/sizing and offers the benefits of driving softer lead alloy bullets faster, without barrel leading, to name but a few, but major differences.

Sure, we could debate these findings, but maybe at another time. Today, I’m going to show you a bare- bones basic way to PC your cast bullets.

How To…

First off, we need to start with dry, clean cast bullets, free of any oils. Static electricity is what makes the PC stick to our lead projectiles, so we don’t want to fight this with any contaminants. So I’ll describe how I PC smaller batches of 100-200 bullets at a time. It’s easy, effortless, and I’ll tell you why I do it, besides the already listed benefits.

Four Steps To Perfect PC Bullets

1: Dump your bullets in a clean plastic container. I used a cheap Tupperware type container and have used it several times. It’s okay to leave excess powder in the container, as long as you keep the lid snapped tight. We don’t want to allow any moisture from humidity to rear its ugly head, or you’ll be fighting the whole coating process.

3: Now dump your bullets onto a piece of parchment paper which you thoughtfully placed on your designated cookie sheet, or pan. I’ve stacked bullets 3-4 layers deep, with no problems. There’s no sense in wasting time standing them on end. I’ve never seen a difference in bullet smoothness, or accuracy by dumping them, as long as you shake off excess PC!

4: Now place your tray in your pre-heated oven. Bake for 20 minutes and remove them. Wasn’t that easy? You did very little work yourself and the results are spectacular. I’ve started using a clear PC to keep with a traditional look, but have no problems using other colors. It’s funny how PC can offend so many traditional bullet casters, but I truly feel they are missing the point and advantages of PC bullets.

Sizing

If sizing is necessary, a $20 LEE sizing-die is all you need. It screws right in to your singe-stage press and collects your sized bullets in the container the die comes in. I usually hold about 15 PC bullets in my right hand and feed them through the sizing-die, as my left hand operated the press handle. It’s much faster and easier than my RCBS Lubrisizer.

The bullets are a pleasure to handle, won’t gunk your loading dies up, keeps the lead from oxidizing and the lube from drying out. Different colors can be used to color-code your handloads. I could go on and on, but the main reason is ease. The older we get, the easier we like things, especially when we get great results, with some added bonuses.

You can call me a Powder-Puff PC’er, but I don’t care any. I’ll be at the range or in the woods shooting or hunting while you’re pumping on your lubrisizer.

If you have any questions, or wish to see how I do anything, give a shout! I’ll be happy to share; after all, we’re all in this together.