DIY Gunleather

It's Easier Than You Think

The world of concealed carry is brimming with cutting-edge synthetic materials and complicated designs. They often promise to remedy every problem encountered when trying to pack some heat. Kydex and other polymers seem to dominate the holster market, especially with us younger guys. It’s cheap, rigid, molds well and does a great job of retaining its shape — and the gun.

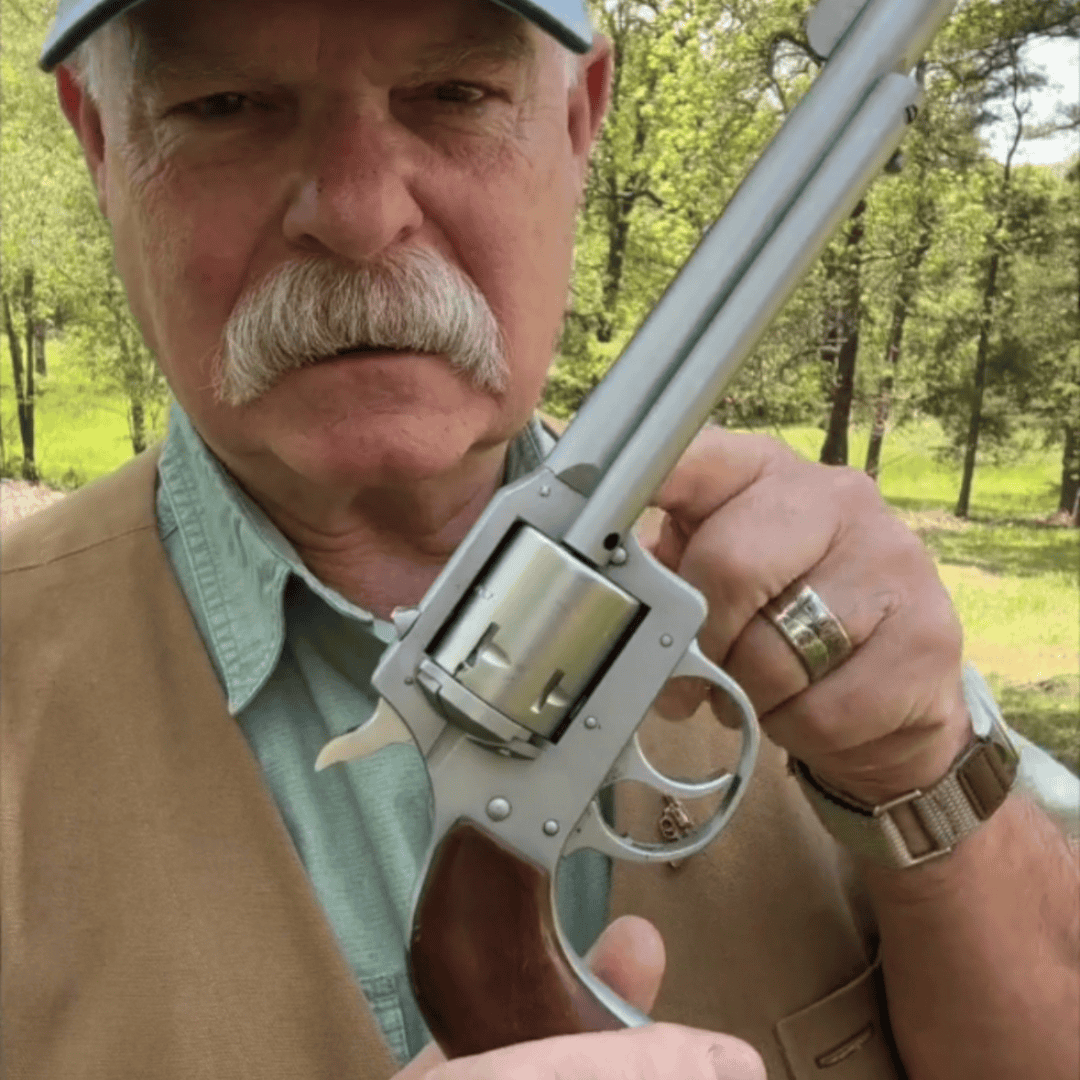

But — leather has a spirit, a class to it plastic can’t touch. People have been using leather since before history was penned, and its value as a material has yet to wane. Many still prefer leather holsters to their synthetic counterparts, and more often than not I forego rigid practical plastic for supple, old-world cowhide.

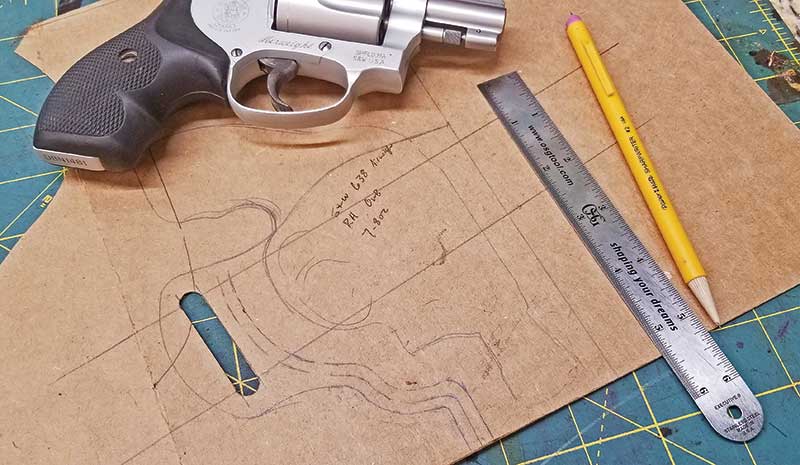

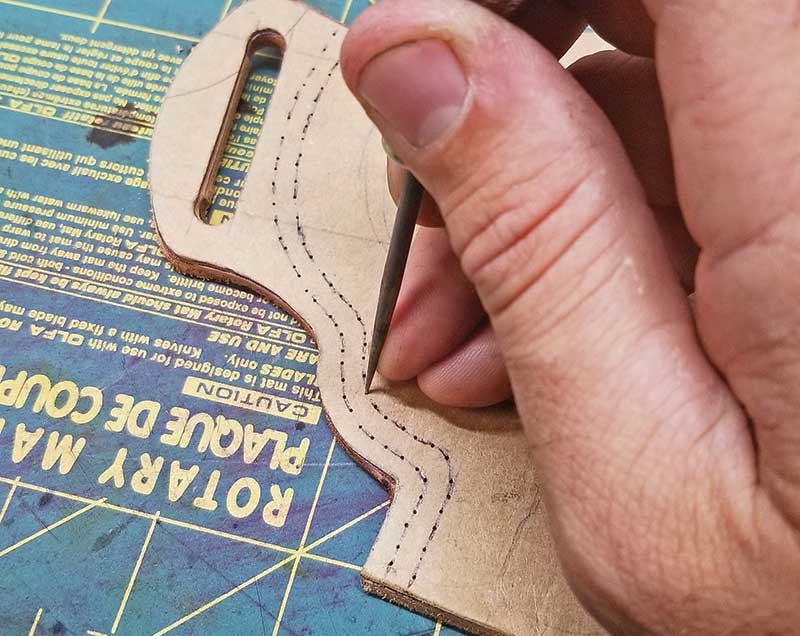

I enjoy making my own holsters these days and readily confess I’m no expert. Call me a hobbyist with a few years under my belt — and experience to share with you. You might find creating your own gear will save you money — and quickly become a satisfying hobby.

This is a simple process at its core but can be as creative and customizable as a person can dream. Stamping, tooling, texturing, dyeing and other decorations add to the overall look of the holster but aren’t critical to making a quality piece of gun leather. It’s so satisfying to carry a gun securely in a holster you made, and I have a hunch you’ll soon find this out for yourself. Keep in mind there’s plenty of YouTube videos showing this process so give some a watch to answer questions we didn’t have the space to cover here. Now, go do it!

For more info: