Do You Really NEED

A Lathe And Mill?

Well... Maybe

“I’m thinking of buying a milling machine or a lathe for gun work. What do I need to buy?” It’s part of reader mail all the time, and I always take the time to answer. My experience may save you loads of money, along with frustration, divorces and having unused machines slowly rusting away in the garage.

Which machine tools do you actually need to do the average bit of gun work? Not any, actually. But often, the “want” gets in the way. These two points can often result in a collision of a smoking pile of charge card receipts and your sanity. Let’s cut to the chase to help you make some informed decisions concerning how much mill and lathe you “need” right now.

Or just maybe — the lathe or mill you don’t need at all?

If your hobby gunsmithing consists of changing stock sights, grips, accessories on AR platforms or GLOCK-style handguns, and even some DIY 1911 “drop-in” parts fitting, then you don’t need any machine tools. A good set of punches, small hammer, gunsmithing screwdriver set, needle nose pliers, a well-lit place to work and reference materials pretty much fills the bill. If you’re going to start having to “fit” some parts, then stones, high-quality needle files, various grits of wet-or-dry papers and maybe a Dremel-style tool might be in order. But certainly no need for a mill or a lathe.

The Next Level

If you decide you want to do some customizing beyond what you can do with hand tools alone, then you might want to start looking at a medium lathe and mill. If you’re going to cut dovetails, then you have to have at least a benchtop mill properly dialed in. That medium mill (along with about $1,000 worth of tooling) will have you doing custom sight installs and the myriad of other jobs a precision cutter can accomplish. Need to widen a rear fixed sight? Drill a precision hole? Mill a channel to fit a new front sight? Drill and tap a hole in a top strap? Slab a revolver barrel? The list is endless, and having the mill makes the job easier and more precise than trying to use files. Trust me on that.

A lathe allows you to make a firing pin, turn a screw down, bore a concentric hole, thread it if needed, turn a precision pin, bore a revolver cylinder, crown a muzzle, chamfer the front of a revolver cylinder and, like the mill, the list is endless. With a lathe and a mill, if you can imagine it, you can eventually do it once you get the skills and the tooling to go with it.

The tooling is something people don’t think of when they start this dream. If you spend $2,500 on a mill, expect to spend about the same on tooling eventually. Right off the bat, you’ll need a $350 milling vise, at least $100 worth of mills, indicators, parallel bar set, a fly cutter and a few other bits would get you going. Sure, a couple of end mills and a cheap vise will get you making chips, but you’ll soon be frustrated, so dodge that miss-step right off.

If you have the basic tools already, the add-ons for a lathe can be less, at least at first. Carbide cutters are the way to go for beginners, and I’d upgrade the tool post to a quick-release one. But just as with the mill, you’ll soon be nosing through the Grizzly or MSC Industrial Supply websites playing, “Gee I wish I had one of those …”

Actually Buying

Remember, a small lathe or mill can do small jobs but they can’t do big jobs. A good quality medium lathe or mill can also handle tiny, precise jobs easily. People usually make the mistake of buying a “cute” Harbor Freight 10″ mini-lathe, thinking that’s all they need. That 10″ is the distance between the lathe chuck and the tail stock, so that tells you in reality, anything over about 6″ or so won’t fit, and diameter is restricted too. The mini- and micro-lathes have zero power and, frankly, are hard to manage since they’re so small. For turning a firing pin or maybe making a small screw or pin, they’re fine. I keep one I outgrew almost instantly in my maintenance shop for just those sorts of things.

Ditto for a mill. A teeny tiny cute benchtop mini-mill might be able to handle a dovetail if you know what you’re doing, but they vibrate, get out of “tram” (alignment) easily, and you’re restricted in vertical space, table travel and power. If you build tiny choo-choo train models, maybe, but for gun work, stay away.

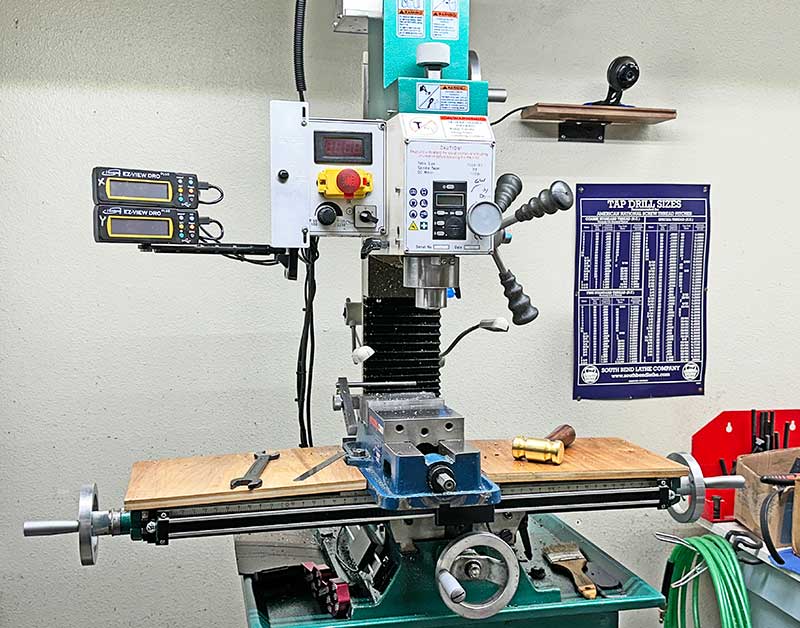

I’ve had a Grizzly Model G0704 medium mill and a G0602 medium lathe for some years now, and they are honestly plenty for what I do. Any handgun work is possible on either and if I need to fuss with a really long rifle barrel, I have access to a friend’s bigger lathe. The weight and overall strength of my machines make them stable and accurate. If you’re going to pull the trigger, I’d start at this level, honest.

I’ve done some shop tours on our YouTube channel (fmgpubs) so you might take a peek at those. There is also a wealth of info in other vids there like the Blondihacks channel. She has a wealth of beginner/intro videos that are well produced and spot-on. Nose around, look hard at what you want to do, then make a sound first buying decision. Drop me a note at [email protected] with any questions.

For more info: Grizzly.com (for machines, tooling and accessories); Brownells.com (for tooling)