A Breed Apart

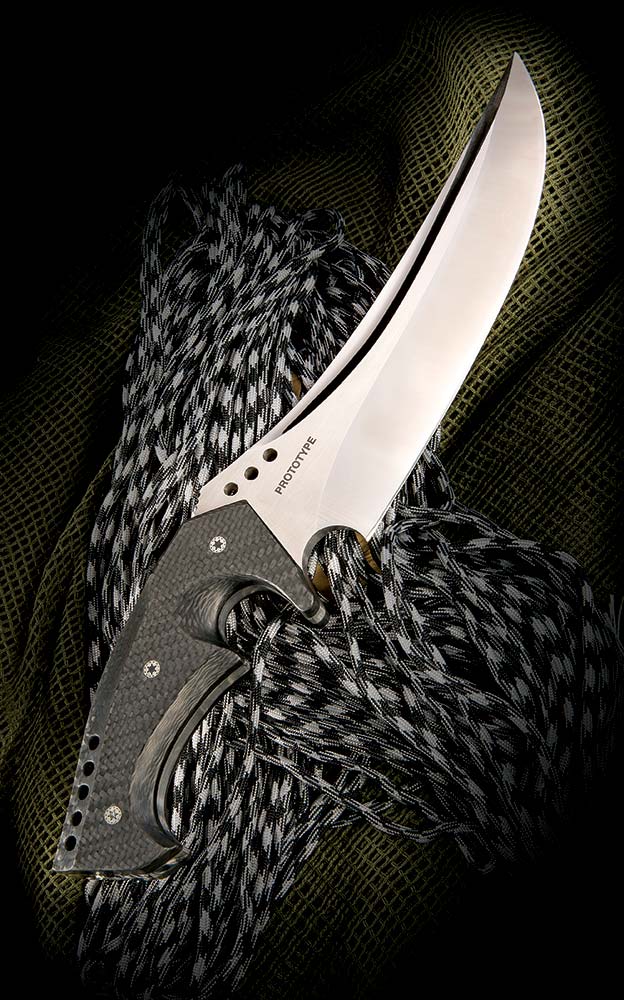

Brend makes as finely a finished knife as you’d expect from a seasoned custom knifemaker but what separates him from the pack are his blades. Perhaps it’s an instinct nurtured during his meat cutting days or maybe an innate sixth sense, but Walter’s blade designs are otherworldly. He can take a standard blade style and smooze it to perfection with just the right curve, angle, or grind to astonish. What some would call Walter’s trademark is the “recurve” — an S-shaped blade edge that’s not only eye-appealing, but extremely effective.

“I prefer recurve blades because of my experience as a meat cutter and a hunter,” Brend explains. “In my experience the recurve blade gives me a quicker cutting edge advantage. The recurve blade works as well on either large or small knives.”

For starters, the recurve adds length to the cutting edge of a blade, giving it more cutting power. It works particularly well on draw cuts, the manner in which most slicing is done. When drawn toward the user the raised slope, or top of the S-curve, tends to dig into the subject rather than slide over it. This holds true on both normal slicing tasks as well as slashing moves associated with combat.

Regardless of blade style, Walter’s blades stand out for their flawlessly smooth lines and exquisite sculpting. He starts with beefy steel, often one-quarter inch thick or more, allowing him to obtain the deep grinds and grooves seen flowing throughout his blades. Regardless of style — whether it be an upswept trailing point, wicked Japanese tanto, or gracefully curved drop point — Brend’s interpretations stand out from the crowd.