Building The Brand

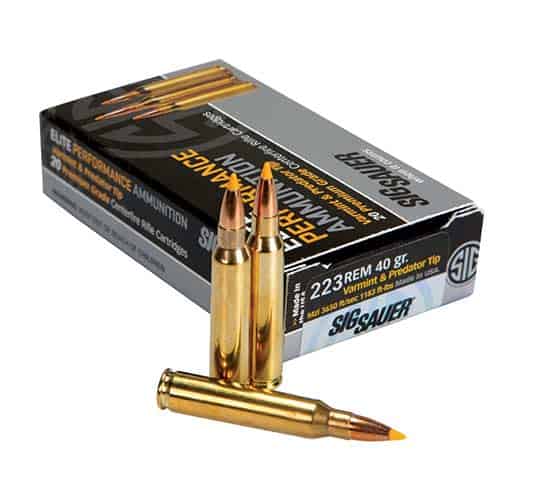

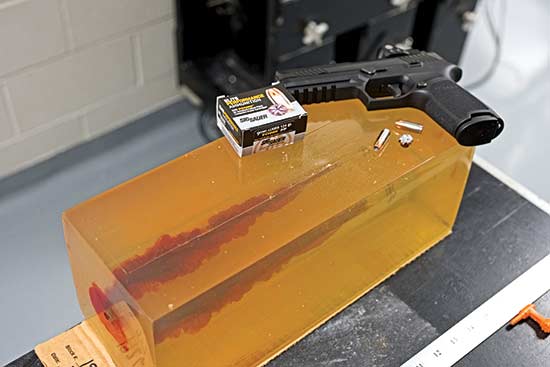

I’ve been doing quite a bit of shooting of SIG’s new “Elite Performance Ammunition” during gun tests and have found it accurate, consistent and beautifully made. As they’ve expanded their load line-up, I’ve referred to my notes and found the numbers continue to be consistent through the product “lot numbers” — even from the early days.

Since the beginning, SIG ammo has been manufactured by SIG, in their own plant, with production initially done in March, 2014 in Kentucky. After much searching, SIG found a new location, offering plenty of room to expand, in Jacksonville, AR, moving ammo production there in early 2017. SIG started with a clean slate and sent a team literally around the world buying top quality loading equipment (often inventing their own too). Their commitment to distinction shows in the final products.

When I was invited to visit SIG’s new ammo plant in Jacksonville, I was honestly looking forward to seeing exactly what the secret to this surprising success really was. Once I met the team, saw the employees in action and got a first-hand look at the honest passion for no-compromise excellence, it became clear once again there was no magic — just that hard work and dedication thing. Funny how that works.