Reloading

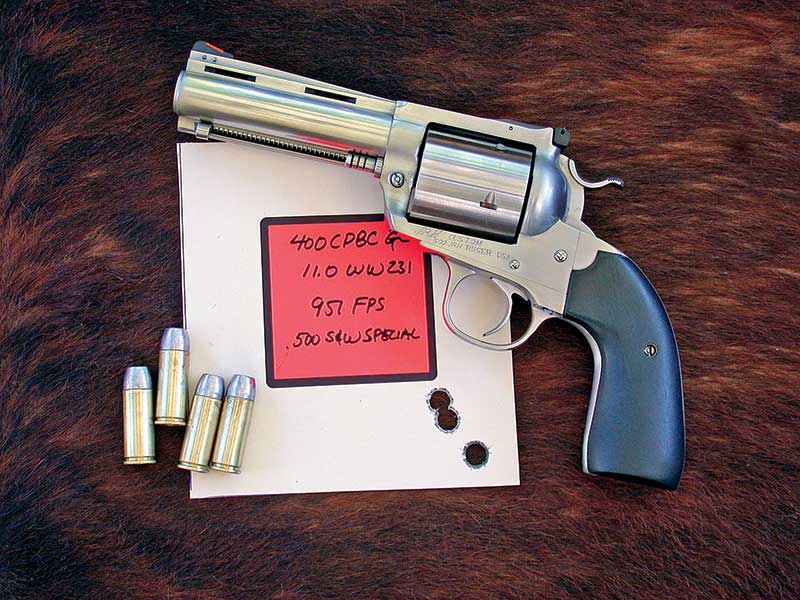

Next it was time to go to work at the reloading bench to come up with loads for the .500 Special. I found it necessary to modify the RCBS .500 Magnum dies to accommodate the shorter cartridge. The expander button extends too far into the Special case and the Special case was too short to reach the crimping shoulder of the seating die; both were shortened appropriately. For powders I chose some of the same propellants I normally use to produce every day working loads in large capacity sixgun cartridges, namely Hodgdon’s TiteGroup and Winchester’s 231. My goal was to come up with relatively easy shooting loads in the 1,100-1,200 fps range using bullets from the Barnes 275 DPX up to the Cast Performance Bullet Co. 400-grain LBT Gas Check.

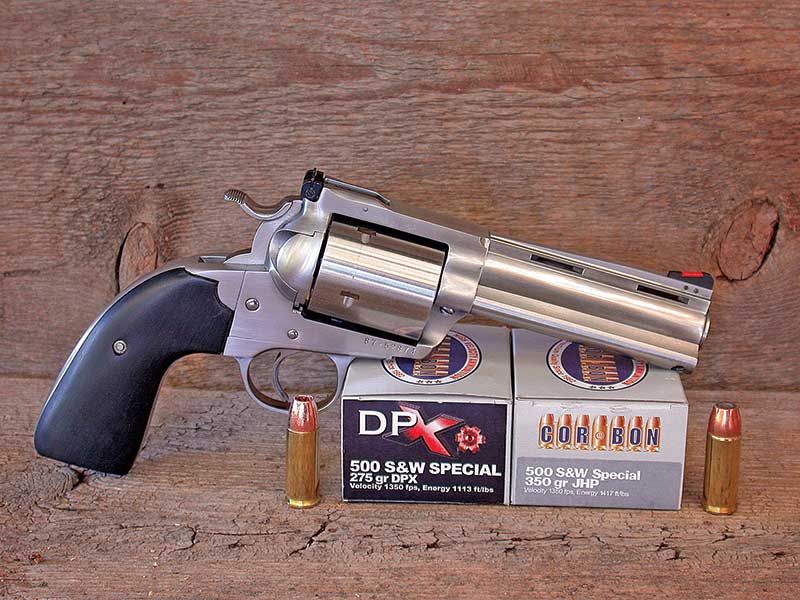

For bullets I could choose from the Barnes 275 DPX, Sierra 350 JHP, BRP’s 380 designed for the .50AE as well as a 370-grain .500 hard cast bullet, the CPBC 400-grain hard cast LBTGC, and a couple of hard cast bullets of unknown origin weighing in at 325 and 335 grains.

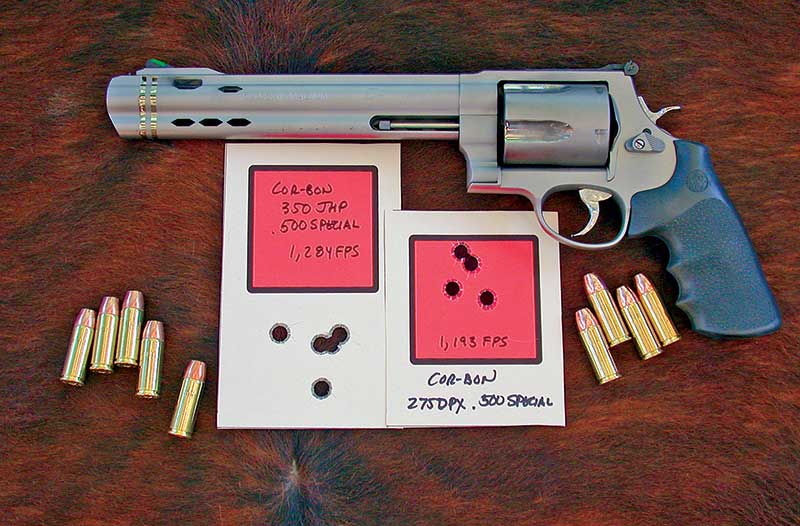

With the Barnes 275 DPX over 10.5 grains of TiteGroup, muzzle velocity is 1,170 fps from the 83/8" S&W Model 500, basically duplicating the Corbon factory loading, with a 25 yard group for four shots of 11/4". With the Sierra 350 JHP over 11.5 grains of TiteGroup, muzzle velocity at 1,150 fps is about 125 fps slower than the Corbon factory load, however it shot into a very pleasing 7/8".