Thoughts On The Lyman 429421 —

Elmer Keith’s Favorite

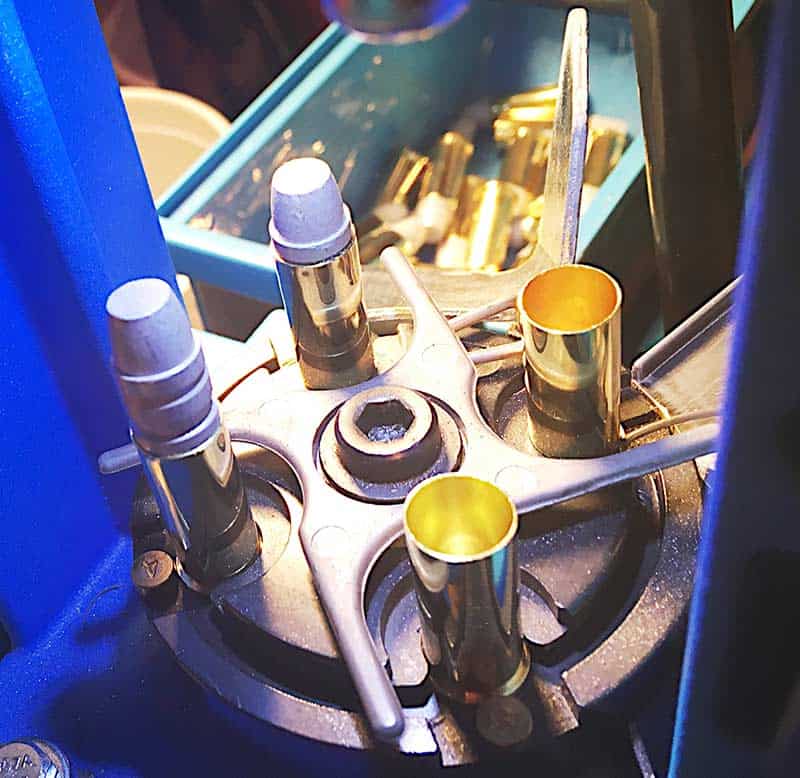

It’s always fun walking along the footsteps of legends, experiencing the same things they discovered. It helps us better understand them, rather than just reading their words. It adds realism by providing us something to touch, see, smell and hear. Sit back while we analyze Elmer Keith’s favorite .44 bullet, the Lyman 429421. It will be a review of sorts for you older codgers, while hopefully opening a new world for beginners.

The Start of Things .44

Back in 1927, at the ripe old age of 28, Elmer designed his 250-grain solid Ideal #429421 for the Lyman Gun Sight Corporation. This was the first of Elmer’s bullets and the one probably responsible for the term “Keith” bullet. This was followed by two 235-grain slugs. The Ideal 429422, a hollow-base design and a hollow-point version of Ideal #429421, with solid base.

Elmer was very particular in what he wanted for his bullet designs, being three full diameter driving bands, as well as a square lube groove. The front driving band would true up the cartridge in the cylinder and cutdown on bullet jump from cartridge case to barrel throat.

“The greatest strain on a sixgun bullet comes on the front band when it jumps straight ahead to the rifling and then has to engage the rifling and start spinning,” he said. “My design cuts this slippage to the minimum, and this forward full driving band scrapes the bore clean with each shot. The bullet has 2 heavy forward bands to take and hold the rifling with only the deep beveled crimp groove between, then a big deep, square lubrication groove, to hold adequate supply of lubricant to properly lubricate the bore.”

Elmer usually had three different loads for each caliber, being a light target load, a heavier medium load, and lastly, a heavy load. His heavy loads sometimes pushing the limits of the guns firing them.

The .44 Special Loads

For .44 Special, Elmer recommended 5 grains of Bullseye for a light load, running around 700 fps. His 7.5 grains of Unique for a heavier load (1,000 fps), or 17 grains of 2400 for 1,200 fps, for his heavy load. This last load was the impetus leading to the development of the .44 Magnum.

Square Lube Groove

Everyone seems to cling onto the square lube groove Elmer designed. Any bullet mold not having one disqualifies it as being a “true” Keith bullet. While this is true, is it necessary?

Back when Elmer was living in his one room cabin in Durkee, Oregon, he often used water pump grease as a bullet lubricant. With a viscosity of jelly, a square lube groove would indeed be necessary to hold the pump grease before seating the bullet. With today’s more efficient bullet lubes, the lube groove is unnecessarily large. It can be half its original size and still hold enough of today’s improved lubes to prevent leading.

Plus, casting bullets with round lube grooves is much easier. As molten alloy cools, it shrinks slightly, just enough to pinch the square lube groove dimension of the bullet mold, effectively holding itself in place. It usually takes several taps on the mold handle hinge pin to drop freshly cast bullets with square lube grooves.

Three Equal Width Driving Bands

I agree with Elmer on this point, but it was a point of contention with Lyman. Customers complained about not being able to load their cylinders with the 429421 bullets. Lyman decided to solve the problem by narrowing the front driving band. Lyman also went with a radiused lube groove around this time. Elmer said it bastardized his design by doing this and I wholeheartedly agree.

As Elmer stated the front two bands take and hold the rifling with the front driving band taking the brunt of the force while engaging the rifling. This is why LBT styled bullets having radiused flat nose designs, are so accurate. Their whole body is one huge driving band engaging the rifling.

Sentimental Favorite

Despite the minor frustrations of the .44 Keith bullet, it is still a favorite of mine. I shoot hundreds of pounds of them yearly, in all calibers. It’s a performer, even by today’s standards with its accuracy and game taking performance. It drives straight and true in game animals and is relatively flat shooting.

While cast bullets of LBT design can give the Keith slug a run for the money, the one thing they can’t do is scratch the sentimental itch all sixgunners have shooting a slug designed by the master himself. Nothing beats thumbing back the hammer of your single action sixgun, getting ready to unleash a Keith slug at a distant rock or critter.

The resounding smack is sure to put a smile on your face just as Keith bullets have been doing for the past 105 years.