A Behind-The-Scenes Tour Of Republic Forge

Bobby was waiting for me in his new red pickup outside the baggage claim doors at the Amarillo airport. Driving through Hereford, the beef capitol of the world, then through Deaf Smith County rekindled stories by Skeeter Skelton. Bobby noticed my smile as I mentioned it, as true pistolero’s know the significance of these locations.

A Quick Hunt

The hour-plus trip to his shop was quick, and before you knew it, we were in Friona, Texas, home of Tyler Gun Works. After checking into my room and a fine Mexican meal with his family, Bobby and I went scouting for antelope, as we would squeeze in a hunt in two days for the opener. During the interim, I would be taking pictures of Bobby’s shop for an article.

Jason Cloessner of Lipsey’s and his son, Evan, joined us on Saturday. The hunt was a success. Evan got his goat first, and I followed two hours later. More on the hunt in another article.

Republic Forge

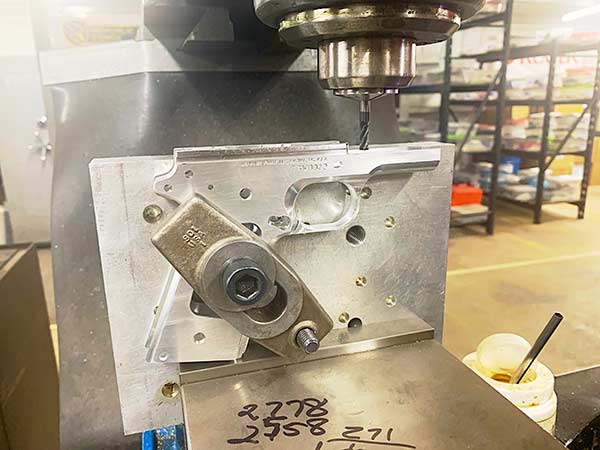

It was Monday morning, and you never know who you might bump into in Texas, it’s that small. After coffee and Tereza sausage, egg and cheese tortillas at Bobby’s house, it was off to the Friona, Texas shop for more pictures. After greeting Dusty, Bobby’s lead gunsmith, I see Bob Maw, owner of Republic Forge running his Bridgeport milling machine.

Bob’s shop is very close to Bobby’s in proximity, making it a kind of two-for-one deal. Knowing Bob for years, we exchange greetings, handshakes, hugs and insults. He then explains to me, in great detail, how he was meticulously tweaking the rails of a new build he was working on. I’ve handled several of Bob’s guns over the years, and they are, without a doubt, some of the most beautiful pistols in existence, as well as the most accurate 1911’s I’ve ever had the privilege to shoot.

It's In the Details

What separates Republic Forge from everyone else is their attention to detail. Every gun starts out as 6.5 pounds of 4140 forged billet, then heated to 1,400 degrees and pounded to rough shape, strengthening the steel. Then, they are machined oversized to be hand-fitted using Bridgeport milling machines. No CNC machining here! Or MIMS parts, for that matter! Being hand fit, a personal feel is obtained that CNC machines can’t produce. After milling comes the deliberate and delicate ministration of files and stones for that “custom” feel everyone loves. This is followed by hand polishing.

Tolerances are kept to a bare minimum, with no two guns being the same. Hand-fit parts mean they are not interchangeable with other guns — which is no secret to Republic Forge’s cult-like followers, who know how accurate and beautiful they are. As a matter of fact, most of Republic Forge’s business is from repeat customers wanting another gun. All this personal attention to detail means a higher quality custom pistol but obviously also a lower production rate, which is just fine.

After the guns are polished to perfection, they are blued or color cased by Tyler Gun Works and then fitted for stocks, many times also by TGW, with either gorgeous mastodon ivory, ram horn or exhibition-grade walnut.

I got to watch Bob fit a slide to its receiver and also fit its oversized barrel to the slide. With calipers, pin gauges and gauge blocks, Bob masterfully had everything fitted and running smoothly with absolutely no play to the moving parts. You can’t get tolerances this tight without skilled hand-fitting throughout the entire gun.

Bob Maw

Bob is a Vietnam-era Apache helicopter pilot, making his company veteran owned. His passion for John Browning’s 1911 is the drive for Republic Forge’s existence. He bought the company in December of 2017, wanting to simply build the best 1911 possible. Many people believe he has succeeded in this quest. Bob was also a competitive shooter and knows the mechanics to wring out all the accuracy humanly possible from a 1911.

Republic Forge has a reasonable turnaround from order to delivery. We’re talking months, not years. And their customer service is flawless. In the unlikely probability anything should go wrong, it will be handled professionally. So, if you’re looking to have a museum-quality 1911 that shoots accurately, check out Republic Forge in Friona, Texas. https://v2.republicforge.com