No Pistol Primers?

How About Rifle Primers?

Can I use small rifle primers in a pistol cartridge? The simplest answer is “no,” so that’s what I usually tell people.

I asked a specific question to my contacts in the ammo industry: “If a person only had small rifle primers, could they safely load handgun cartridges?” Almost every one of them told me “No” right away, followed by, “That’s the official answer.”

Before I go further, I’m going to tell you it is irresponsible for anyone to interchange load components, period. I tend to use what’s in the Lyman, Speer and Hornady reloading manuals because they can test loads at a higher capability than I can.

Having said this, I have lots of small rifle primers (SRP) and a dwindling supply of small pistol primers (SPP). With gun, ammo and component sales at record levels, don’t expect the ammo and primer supply to catch up anytime soon.

Architecture

Small pistol primers (SPP) and small rifle primers (SRP) are 0.175″ in diameter; large pistol primers (LPP) and large rifle primers (LRP) are 0.210″. There is a cup height difference in LRP and LPP primers, so the question of interchangeability is a “No.”

Boxer primers consist of a relatively soft brass circular cup with a pressed-in anvil, normally of a slightly harder brass. Between the base of the cup and the anvil is the priming compound. Most modern primers are non-corrosive, usually containing lead styphnate (an impact sensitive explosive), or other compounds.

The anvil is a concave dish-like device that looks like an upturned stool with a domed top. If it appears the “legs” of the anvil, which point toward the bullet, are not flush with the rim of the primer cup, they aren’t. The act of seating the primer should squish the anvil into the pellet slightly when the primer is seated flush in the cartridge.

SPP and SRP don’t really appear different dimensionally, or even regarding the amount of priming compound inside. However, SRPs are generally made of a thicker material than SPPs. This is a good argument for not working up loads with SRPs. If you were gauging the efficacy of your load by primer deformation, using a cup with thicker or harder brass may send your loads past safe levels.

Before I go further, let me reiterate. Using SRP in handgun applications, unless it is specifically listed in a published reloading manual, is not recommended. Using loads I’ve tested over and over again, I loaded the same cartridges with SRP. Like many (un)scientific endeavors, I kept everything else the same: same dimensions, same load, bullet, temperature and loading method. In most cases, I was able to use the exact brass head stamp. I tested dozens of cartridges besides what I shared with you and used load densities that were at least around 80%.

Findings

Using an SRP in a handgun does not result in unpredictable velocities. Given the same load, using an SRP did not necessarily result in higher velocity.

Wolf SPP gave a much lower standard deviation than I predicted.

This is a no-brainer, but the lower the standard deviation, the more likely the round is accurate.

If the cartridge cycled well with SPP, it cycled well with SRP also.

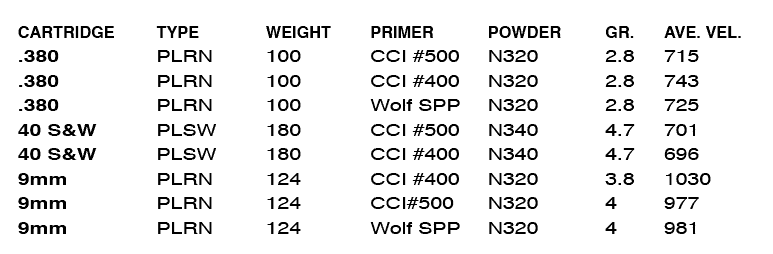

The chart shows some of the loads I tested.

Just because I tested some loads and they worked fine, it does not prove all loads will have the same degree of success. The only thing I have proved here is the guns I used to test a few loads were robust enough to contain the rapid expansion of the loads tested. That’s the official answer.