Handloading: Make Your Own Jacketed Bullets???

If anyone tells you one can’t swage bullets at home using standard reloading equipment, tell them that’s not entirely true. If you have not tried this before, I hope to encourage you to experiment.

What Ya Need

Home swaging 45s requires a rigid reloading press, a reinforced bench, soft lead, a .243 Winchester reloading die and some .45 caliber jackets. You will also need a Lee Classic Sizing Kit in .451. I use .45x.580 jackets from Center X Bullets. Center X Bullets makes several lengths, but the .580 worked best for me.

I used my Hornady Lock-n-Load Iron Press and a Lyman Universal Press Stand to create a robust enough platform. The Iron Press is a huge chunk of metal that can handle the pressure of light bullet making.

The Process

You put a measured amount of lead into the copper cup and force it into a die shaped like the desired bullet. We are using a .243 Winchester sizing die. Most swaging operations occur in phases, where the bullet maker forces the materials into an intermediate shape before the final bullet shape. Center X has already provided an intermediate shape.

Bullet makers generally use lead wire. Once the lead is cut to length, it is forced into the cup, so the lead conforms to the interior and fills the space. I used the ram from a .410 Lee Classic Bullet Sizing Kit and pressed the lead wire into the cup with an arbor press.

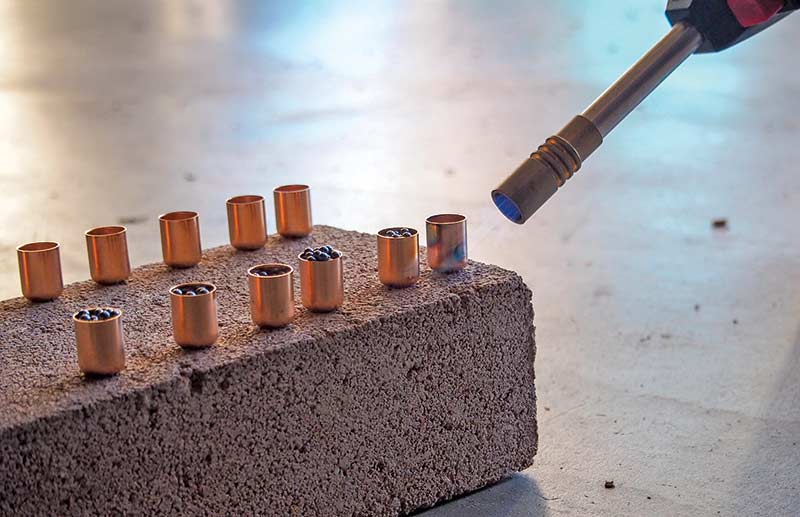

Then I tried the easy way. I weighed out some reclaimed shot, poured it into the cup and then melted it with a propane torch. Copper melts at 1,983º F; lead melts at 621º F. When heated, it will cause the lead to flow and anneal the copper, making it more ductile. Annealing is unnecessary for copper bullet cups, but heating won’t hurt it, except for discoloration.

I weighed the jacket and lead together, adding lead on the scale until it was 230 grains. I wasn’t surprised to find all the lead didn’t fit into the cup until it melted. Melting the lead into the cup adds another dimension: Reducing the chance of jacket/core separation. Hog hunters, take note.

Once the filled cup is cool, cover it with a generous coat of sizing lube. There are several good products out there and I find the best ones are lanolin-based. Center X Bullets makes a particularly good lube.

After removing the de-capping assembly, use the ram from your Lee Classic Sizing Kit to push the cup face up into the .243 sizing die. You’ll be pushing your bullet into the die part that shapes the .243 cartridge shoulder. I use a standard punch to push the bullet back out of the die.

The .243 has a 20-degree shoulder — perfect for forming the bullet nose of a 45. Form the nose incrementally, punching it out to inspect it. Keep the bullet well lubricated.

Under Pressure

It takes a tremendous amount of pressure to shape bullets and many hobby bullet makers make longer and more robust custom handles for their presses. I have my press mounted on a Lyman Universal Press Stand attached to a sheet of heavy plywood, mounted directly on a steel stand with almost no overhang. I’m looking at mounting it on a steel plate for bullet making.

After forming the bullet, run it through a .451 sizing die. Notice most lead bullets are usually 0.452″, but jacketed bullets run 0.451″. This, of course, is contingent on the land/groove diameter of your gun.

The first time I made these, the non-tapered part was 0.444″ long before it went to the truncated cone shape — the nose cone was too short. You will need to experiment, but having the nose of the bullet slightly less than 40% of the overall length should be okay.

I used the 5.3-grain Clean Shot load printed on the container of Clean Shot, and they sailed reasonably well. My only complaint was I made a JSP and not a JHP. No matter how hard I tried, these bullets sailed through my gelatin blocks. I guess I will have to experiment with making hollow points.

Another time we’ll talk about using .40 S&W expended brass rather than a copper cup or 9mm brass to make 10mm bullets using a 220 Swift die.

The sky’s the limit for curious people.