Lead Bullet Technology (LBT)

Leads The Way

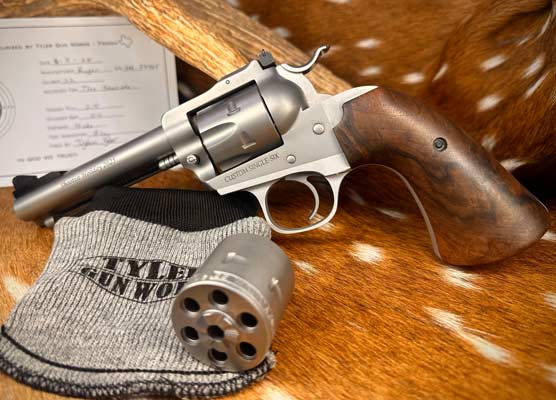

The Bullet Casting Bible to my way of thinking along with LBT molds, hardness tester

and a few cast bullets from same. The .45 Colt Ruger Bisley was the first gun Tank

polished the cylinder throats to proper dimensions and did other improvements.

Combined with LBT techniques the gun shoots extremely well!

Like many, gun magazines have corrupted me. Hopefully, I’m returning the favor to you. One of my biggest influences was the day I read about cast bullets and Lead Bullet Technology molds almost 35 years ago. I already knew the benefits of cast bullets from reading Elmer Keith and shot factory cast bullets. Back then, everything was plentiful, cheap, and available. But being a hardcore do-it-yourselfer, I wanted to carry things further by casting my own projectiles.

I wanted to be in control of making my bullets, with the alloy of my choice so I could choose its hardness, diameter size and style of bullet. I wanted to be able to make bullets so if any supply shortage ever occurred, I wouldn’t be dependent on anyone or anything to interfere with my shooting. Now here we are, more than three decades later, and the very thing I feared has come to fruition. Thankfully, I’m stocked pretty good in primers, powder, lead and more molds than I’d ever need.

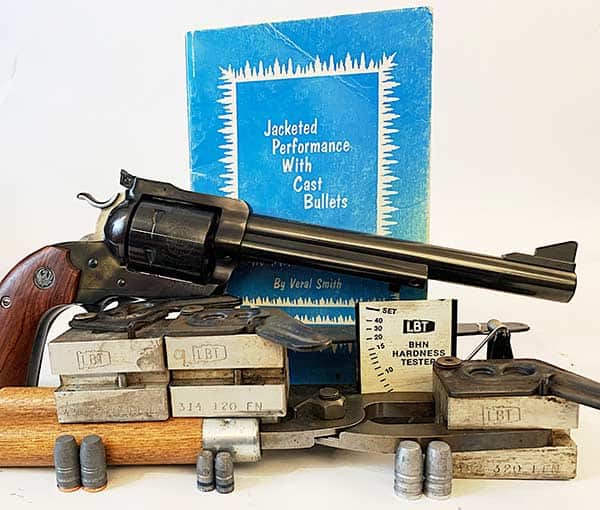

The vent lines are obvious letting air escape to prevent air bubbles in bullets.

The cavities are polished with no edges to allow easy release. This bullet is a

.430” 320 grain LNFDCGC design, or long flat-nose, dual crimp groove, gas

check design. The dual crimp groove allows seating the bullet further out for Ruger Redhawks.

Casting Catalyst

The specific article was written by Ross Seyfried. Fellow greybeards and inquisitive youngsters know of whom I speak. The article was about Lead Bullet Technology (LBT) molds and the modernization of the bullet nose these molds provided.

Veral Smith was the sole proprietor and a bullet-casting genius. While the Keith bullet developed a notoriety for killing large game, Smith carried things a bit further, improving on the “Keith” design. He determined it was the nose flat that was responsible for the wound channel. The bigger the flat, the larger the wound channel.

LBT bullets are radiused flat-nosed design with shallow, radiused lube grooves. His lube is very efficient, so you didn’t need a lot of it to do its job. The entire bullet body acts as a full diameter driving band, while providing more bearing surface, keeping bullet skid to a minimum. This improves accuracy for high-velocity loads.

His two basic designs are long, flat-nose (LFN) and wide flat-nose (WFN). LFN bullet noses are wider than standard “Keith” style bullets of the same diameter, meaning they will create a larger wound channel.

The radius flat-nose design has more of the bullet’s weight outside of the cartridge case, allowing more space for powder. More space equals less pressure when heavier charges are used with the LBT-style bullets.

The LFN bullets are more aerodynamic than the WFN style, meaning they will shoot flatter at long-range distances. They’re designed best for all-around use as their flatter shooting design combined with larger wound channel capabilities and accuracy potential are tops. Yep, dare I say the LFN gives the “Keith” slug a run for its money? Indeed, I do. The categories the “Keith” comes out above the LFN design are penetration and nostalgia. I’ll let you choose, as I still shoot both and can’t make my mind up.

The WFN is just about a true wadcutter design with a radiused curved profile at the nose. Its blunt point loses stability in flight much past 100 yards. So why shoot it, you ask? Because that blunt nose transfers a lot of energy this side of 100 yards. Besides, most handgunners take their game and are limited to 100 yards as a maximum range for a deadly shot. Most sixgunners have an effectiveness of about half that distance but still manage to take game when picking their shots.

While I like both designs. I’d choose a WFN, especially when carrying a sixgun for backup when shots are close.

LBT Molds

Veral Smith knows how to make a bullet mold! He uses a “one-of-a-kind, ultra-precision, custom designed custom built, reducing tracer lathe. This only machine in the world was engineered for the single purpose of producing molds with precision that no available machinery can match.”

I’ll say this about Smith’s molds, they are a joy and wonder to use. While casting, bullets fall out on their own when opening the mold blocks. They cast consistent weight bullets, due to superb venting which eliminates air pockets. Rejected bullets are practically non-existent when casting with LBT molds.

The Casting Bible

Smith’s book, “Jacketed Performance With Cast Bullets” is considered the bible for dedicated leadheads. Its full of useful information, explanations on his bullet designs, how to, bullet lubes, and other topics not covered anywhere else. From beginner to senior caster of the silver stream, you will learn pertinent and useful information about cast bullets.

Alive & Well

LBT is alive and well. Besides their wonderful molds, they still produce excellent bullet and mold lubes, sizing kits and a host of other bullet designs for automatics, leverguns and bolt guns. Check them out at LBTMolds.com.