Reloading Equipment You Cannot Live Without

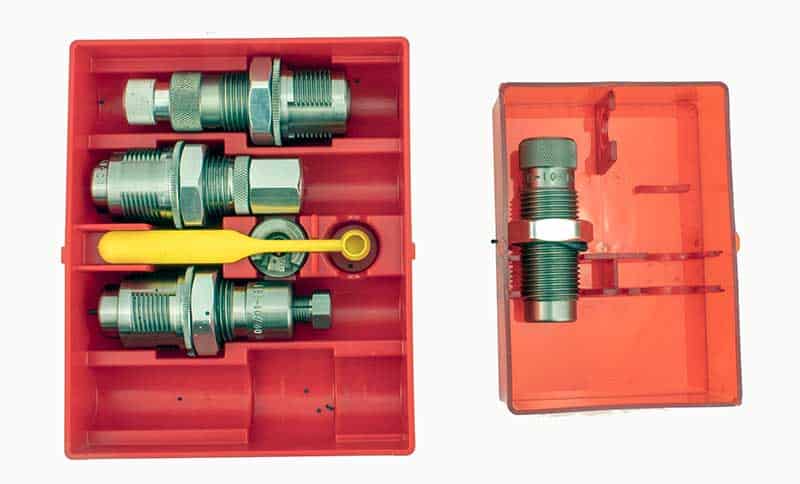

When you buy your reloading press, don’t be shocked to discover you need something else for every caliber you want to reload. It’s called a die set and they typically run $35–$50 per set. What does it do? Pretty much everything. All the reloading companies make them, and a cool thing is they’re pretty much universal. If you can’t find a .41 caliber Lee Precision die set at your favorite gun store, but they have an RCBS or Lyman die set, it will work on your Lee Precision press.

A typical die set will have at least three dies. Some sets such as the Lee Deluxe Handgun 4-Die Set will have, yes, you guessed it, four dies.

Resizing and Priming

The first die in the set accomplishes three tasks. The Full-Length Resizer die resizes the cartridge. You look at a typical shell casing and it looks okay size-wise, but remember all that pressure inside the cartridge as the powder was burning? Heat and pressure cause things to expand, and even though you probably can’t see it, the shell casing you’re about to reload has expanded a bit. With some handgun die sets, you’ll need to put a resizing lubricant on the case for this resizing to do its task. Lee Die sets and some RCBS sets, and I’m sure others, are made using carbide, which eliminates the need for a lubricant. Rifle resizing dies almost always require a lubricant. Pulling down on the operating lever of the press will force the resizing die down around the cartridge to put it back into shape for being inserted into the gun chamber again.

Meanwhile, the die is accomplishing another task. It’s pushing the old primer out. If your press is set up correctly, the old primer is going down the tube — literally. There’s a plastic tube attached to your press through which the old primers slide right down into a pail from which they’re disposed. All of this is happening as you’re pulling down on the press operating lever. Many reloading presses feature a small cup and lever designed for priming the cartridge. Place a primer with the anvil side up in the primer cup and the press will insert it into the cartridge as the operating lever is pushed back up.

Case Mouth Expanding

The next die up is the Expander Die. The first die shrunk the case to its proper size. This one will flare the mouth enough to accept the new projectile. The die has an adjustment so you can set the flare depth as desired, probably experimenting a bit until you get it just right. From that point, it will be set for the same projectile time and again. This die has a flared opening at the top for charging the case with the proper amount of gunpowder.

Bullet Seating

Once the case has been charged, the Bullet Seating Die is used to insert the new bullet into the casing. Set the die in the press and use the rotating adjustment on the top of the die to adjust it for the proper bullet seating depth. This is another adjustment that will be trial and error until you get it right and lock it down. While checking your results it’s important to use a precision caliper to measure the overall length of your cartridge with the bullet seated. This measurement must be precise. Bullets seated too deeply will increase pressure in the cartridge case, possibly beyond specs. Cartridges that are too long due to the bullet not being seated properly may not work in your gun, especially a revolver, and the bullets may not stay seated while being loaded and fired in the gun.

Crimping

The fourth die may or may not be needed, which is why many sets are sold with just three. It’s the crimp die. Some handgun cartridges may require a crimp die to hold the bullet securely in place or at least “unflared” the cartridge case mouth; others may not. Bullets that are smooth-sided will require a taper crimp if any. A roll crimp is used for bullets that have a groove around them to accept the crimp.

Lee Precision Breech Lock Press

One feature unique to the Lee Precision Breech Lock Press is the Breech Lock Quick Change Die System. Dies are normally threaded into the press with the depth adjustment set with a locking nut. Lee Precision designed a Breech Lock Bushing that stays locked in the press and works with Quick Change Bushings on each die to allow the die to be inserted and locked in place with just the twist of a wrist.

Efficiency

I’ve accumulated die sets for each handgun caliber I wish to reload including two .357 Magnum die sets and two .40 S&W/10 mm sets. I did this with the .357 first because I reload both .357 Magnum and .357 Maximum Cartridges, and this allows me to have a die set already adjusted for each caliber. Realizing how well that worked, I got a second .40 caliber die set for my 10mm loads. That way I don’t disturb the adjustments for the .40 caliber loads I’ve got set up on the first die set. You can take your time and accumulate die sets as you venture into reloading different calibers. I even have a couple of rifle die sets, one for .308 and one for .243 Winchester. None of this is hard, and you learn quickly as you work through some initial loads. Always load and measure precisely for both safety and accuracy, and most of all, have fun doing it.