Rust & Dust

The two worst environmental conditions your firearms may encounter are exposure to: (1) salt water/salt air, and (2) fine airborne dust. In comparison to these two, most environmental conditions such as cold, heat, even rain, are minor indeed.

Sea air, especially, is tough on metal. What did they do in the old days? According to Robert Ruark’s memories of the 1920’s along the Carolina coast, Coast Guard boats used to intercept rum runners had “… machine guns and rifles, carefully cherished in scabbards of sheepskin with the clipped wool inside, well soaked in oil to prevent rust…” (from The Old Man and the Boy).

Handling and firing an oil-soaked firearm, especially one with oil in the bore, isn’t such a great idea, but they did the best they could with the tools and technology at hand.

Rust Resistant

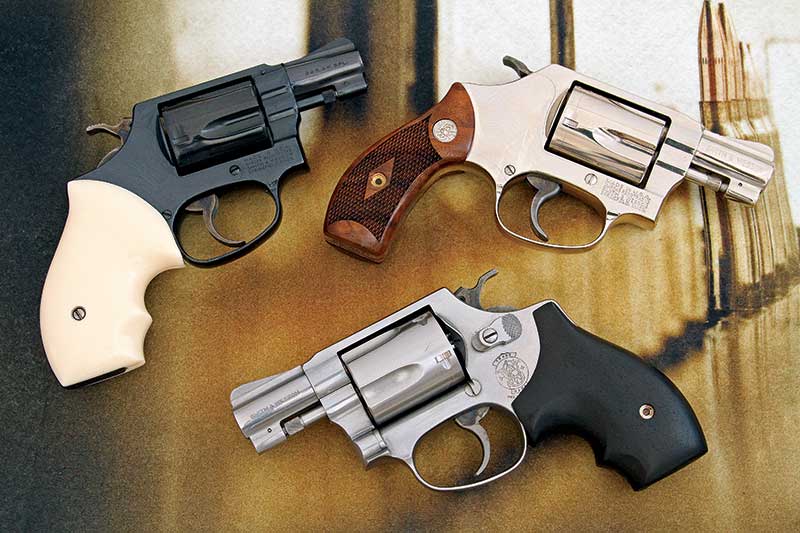

Nickel plating was used on many cheap imported revolvers in the early 20th century. Poorly and cheaply done, such finishes often flaked and peeled. Nickel unfairly got a bad reputation as a result. Properly done by companies like Colt or Smith & Wesson, nickel is a pretty good finish, though a bit shiny and reflective for some tastes.

The younger generations don’t appreciate what a revolution it was when S&W introduced the stainless-steel model 60 in 1965. Demand was so great, especially with Vietnam-bound servicemen, it was years before S&W caught up. Today, there are hundreds of stainless-steel alloys, some of which resist rust better than others. It’s better to use the term “rust resistant” than “rustproof.”

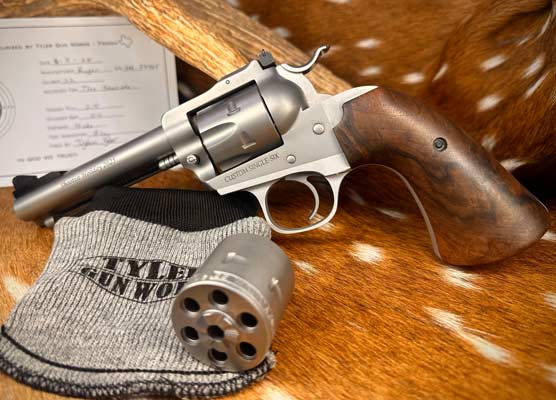

Technology has also given us many amazing new firearm finishes. My favorite is Robar’s NP3+. This process needs to be done by Robar. Some of the spray-on finishes can be very corrosion resistant too, inexpensive, and can be applied by the home hobbyist. Duracoat has a version to simply spray on and allow to cure; another version cured by a short baking period. But it might be argued none of the spray-on finishes can quite compare to a finish like NP3+.

Dust To Dust

These days I’d say fine airborne dust is a worse problem than salt air; or at least, we don’t have any good solutions for it. As most shooters, I’ve had to deal with dust all my life. If land has good, rich, heavy, non-dusty soil, it’s used to raise Iowa corn or Idaho potatoes. Shooting ranges tend to be located on rougher, marginal land or canyons. When the wind blows — there’s going to be dust.

The best solution is to minimize exposure of your gun to dust. When I was shooting in handgun competitions the matches would go on regardless, as long as the targets would stay up. Airborne dust was considered routine. I’d keep my pistol zipped up in a compartment in the range bag, only taking it out to shoot the stage and then storing it away again.

If your work takes you into dusty conditions and you can carry concealed, consider a wind-proof covering garment. If you open carry and have to work when airborne dust is a problem, that’s a tough one, without any really good solutions. Oil and grease hold the dust (can you say “valve grinding compound?”) so it’s best to use as little as possible. Even so plan on field stripping the gun daily. Compressed air to blow away the dust is handy, and pressurized degreasing sprays also work well.

Personally I’d carry my S&W model 13 revolver with Robar NP3+ finish. The beauty of NP3+ is not only does it resist corrosion, the Teflon incorporated in the finish is very slick. Dust and dirt don’t stick to it, and due to its natural lubricity there’s little need for oil or grease.

If you do lube the gun it’s best to use some kind of dry lube. My favorite is Prolix, which is a dry lube carried in a liquid carrier. The liquid makes it easy to apply even in tight spaces; the liquid carrier then quickly evaporates, leaving the dry lube.

None of these are perfect solutions. Those who must deal with airborne dust on a regular basis have my sincere sympathy — and admiration!