1911 Take Down Magic

Detail Stripping Without Tools?

5. Remove the thumb safety and slide lock plunger assembly (on the slender

spring) from the small tube between the safety and the slide-release location.

Sometimes there is a slight kink in the spring to keep it from flying out so you

might need to really pinch it to get it out. Note which end goes in first.

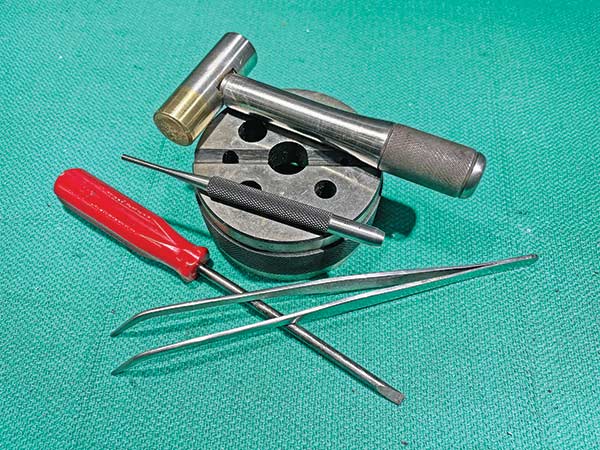

For we mere mortals, detail stripping a 1911-style auto usually means a couple of punches, a screwdriver and maybe a light mallet and a bench block to rest things on. But, John Browning, being the pesky, brilliant gun designer he was, built a secret right into every 1911 out there.

You can take them completely apart using nothing but the parts of the gun itself as your toolbox — right down to the very last tiny spring and pin.

Is this some parlor trick or sleight of hand at work? Nope, not at all. Read on to have your mind amazed at the fact any man could think all this up. I like to imagine the inside of Browning’s brain looking a lot like the screen on a CAD/CAM computer with little images of parts moving around seeing if things fit. In his case, they always did.

13. Use the angled end of one of the long sear spring fingers as

a “screwdriver” to rotate the magazine release screw head. This turns

a sort of tiny cam allowing it to rotate from a cut-out in the frame. It doesn’t

“unscrew” as you expect it to. Once free the assembly can be pulled from

the right side of the frame as a unit.

15. Use the bottom-angled portion of the sear spring as a screw-driver blade and remove the grip screws. Don’t attempt this if the grip screws are very tight. This takedown routine is just to show how it can be done, but you do need to use caution and common sense not to break any parts! The screws can easily become buggered up or the sear spring can be twisted or break. Grab a screwdriver for this step if you need to — don’t be too proud to ask for help from a “real” tool!

24. If you really want to, you can use the thumb safety cross pin to

push in the mainspring plunger (in the mainspring housing), then use

the small end of the safety lock and slide lock plunger assembly

Use caution as it’s under a good deal of pressure! Be warned, it’s

tough to reassemble without using a vise so Roy would bypass

this unless you’re simply determined.

(on the slender spring) to push the crosspin out.

Easing Into It

Use some common sense and don’t over-stress parts. It’s one of those “just because you can doesn’t mean you should” situations. If your grip screws are really tight, you’ll break things. So be prepared to use the correct tools if something doesn’t want to cooperate at first. I find this whole idea works best on well-used original 1911 designs. Modern tightly fitted guns will fight you and lash out expressing their displeasure at your intrusions this way. An old, well-worn 1911 like this WWII-era Colt is “just right” as they tend to be a bit loose and cooperative.

We’re just having a bit of fun here, an exercise showing it’s “possible” to do it. But, I certainly don’t recommend you do it routinely. So be warned, don’t over-stress the bits — or overstay your welcome.

Let’s take a step-by-step look at just how to amaze and astound your friends with your brilliance. I’m thinking a good lead-in might be, “Hey, wanna bet I can completely detail strip a 1911 using no tools at all? Right down to the last pin?”

Spend the winning money on ammo — if you can find any!