Blueing Scratch Repairs

The first thing I do is look at the depth of the scratch, see if any surrounding area has been damaged. That damage needs to be addressed without making a larger repair area.

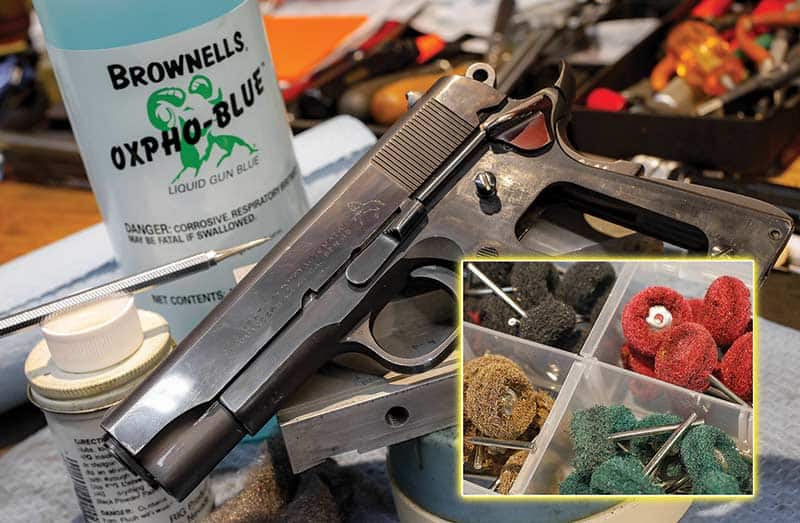

If the scratch is small, I de-grease the area with some acetone in preparation for application of a small amount of instant blue. I like Brownells’ liquid “Oxpho Blue” because it works well and is easy to use. It goes on like water and turns carbon steel blue to protect it from rusting.

I like to go one step further than Brownells’ instructions. I have a small butane torch on my bench, which I use to heat the scratch area. This removes all moisture from the metal, dries any solvent and opens the pores of the metal to better accept the instant blue.

Once the area is clean, decreased and heated, I use a number of tools to apply the “cold blue.” I don’t want to just wash the area with cold blue. I want to only treat the smallest possible area. Washing can change the color of the surrounding metal and make things look worse. Sometimes for a small scratch I’ll use a small needle-like pointed tool to apply a tiny bit of blue to the scratch itself. For larger scratches I use a 000 hobby paint brush or even a Q-Tip. Once the blue starts to affect the scratch, I wipe it off. I don’t want the scratch to be darker than the original blue. If my repair is too light, I start the process over again until I get a good match. Apply oil to the repair as soon as possible once you’re satisfied with the color.