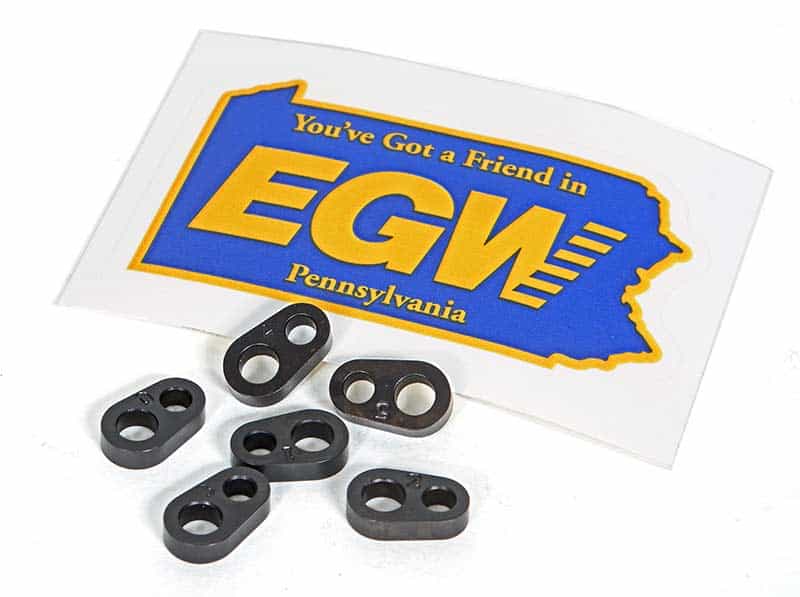

Evolution Gun Works

Tools For Professionals

Founded in 1991 by George Smith, Evolution Gun Works (EGW) is a major aftermarket supplier of 1911 parts and produces OEM parts for many of the major gunmakers. EGW also offers an extensive line of gunsmithing tools.

Smith, who went to night school for Auto CAD (computer assisted design), CNC and Solid Works, also worked for Austin Behlert, a pistolsmith who did pioneering work making compact pistols out of large ones. With this background, it’s no surprise that many of the ’smithing tools he designed are for professionals. Designed to not only do the job well, but to do it quickly and efficiently.

Firing Pin Particulars

The firing pin stop may not seem like an important part, but it is. While it’s rare, a loosely fitted stop can slide down out of place, locking up the gun. More commonly, since it holds the extractor in place, a loose stop can allow the extractor to “clock” or rotate in its tunnel. This changes the angle the extractor hook meets the case head, wreaking havoc with the gun’s feeding cycle.

Recognizing the problem, EGW was among the first to offer an oversized firing pin stop. The extra material allows you to fit it to your gun. Since the location of the channel in which the stop fits doesn’t lend itself to using a dial caliper to measure it, EGW created a cruciform firing pin stop gauge with four different gauges. These range from 0.474″ wide to 0.480″ in 0.002″ increments — a much faster way to fit a stop than the usual file-and-try method.

Since fitted parts are usually a little harder to get out, EGW also sells a neat stop removal tool made by SDM, compressing the firing pin so the stop can be pulled out. It’s much easier than using a punch, especially on Series 80 guns, and works on Browning Hi-Powers too.

EGW also sells the 10-8 Performance Armorer Tool, a reinforced nylon tool reminiscent of the Pachmayr Widget. It’s used to pry out stubborn extractors as well as depressing the plunger to reinstall a thumb safety, both of which are easy ways to scratch your gun if you’re using a metal tool.

Measuring Up

As with the firing pin stop, when you’re fitting a trigger, there’s no great way to measure how tall the shoe needs to be. EGW’s answer is a two-bar set machined into steps. Each bar measures four different heights, for a total of eight sizes from 0.898″ to 0.920″. Insert the bar until you find the correct size and cut the shoe to match.

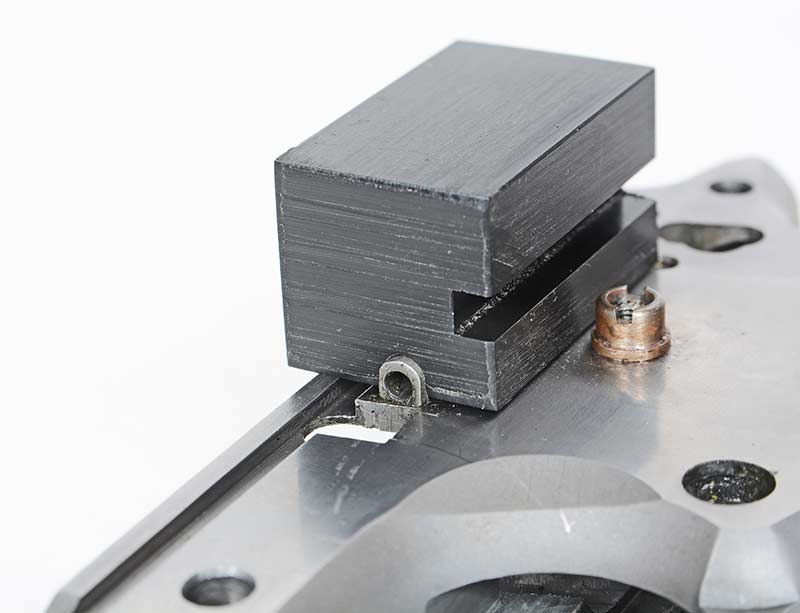

Staking in a plunger tube can be a bit tricky because, well, it’s a tube, and crushing or deforming it is a real possibility — ask me how I know. The rear staking leg is also located inside the magazine well, close to the ejector, making it difficult to get a tool in there. EGW designed a steel bar staking tool that fits in the well and has a clearance cut for the ejector. It also comes with a Delrin nylon block to support the tube during staking. The block has channels cut into it for traditional rounded tubes or machined ones with a more square profile.

Like the 10-8 tool, the Delrin block reduces the risk of scratching the tube, which is usually installed after refinishing, so you don’t spend the next several years with bluing salts leaching out from under it.

Tight Fits

Barrel-fitting tools include a hood length gauge, a barrel-fitting block and a slide bore gauge. The hood tool inserts between the breech face and the first locking lug in the slide, a dimension not particularly easy to measure with a dial caliper. The tool has four separate gauges measuring from 1.313″ to 1.321″. Once you know the correct length, the sides and length of the hood can be cut to fit. The barrel block is used to keep the barrel correctly aligned without turning during fitting, which is critical. I’ve used other designs, but the EGW is clearly beefier. It has two slots for the lower barrel lug, one 0.362″ wide and one 0.369″. There’s also a hole for insertion of a dial indicator so the barrel lockup height can be measured while the barrel is fixtured in place.

The slide bore gauge is inserted into the front of the slide until it stops on one of its four steps — 0.699″, 0.701″, 0.703″ and 0.705″. This provides a quick way of determining what size bushing you need to order or to what size you should cut the one you have. One end of the gauge is also drilled to 0.580″ to check the outside diameter of the barrel.

Fixtures And Cutters

The hardest part of doing machine work is usually fixturing. This can be especially hard on a pistol where a little too much pressure on a slide or receiver can mean major damage. Not only does EGW’s gunsmith plate avoid the risk of damaging slides and frames, its use of indexing dowels, slots and pre-drilled holes indexing on the grip screw bushings significantly reduces set up time.

The versatile two-sided plate can hold slides for machining cocking serrations, top flats and opening ejection ports. It can also hold receivers for any number of operations like beveling mag wells and cutting feed ramps. It can either be clamped upright or laid down flat in the mill vise. EGW also sells the cutters for many of these operations, including a neat double-ended carbide front dovetail cutter. It cuts 0.330″ wide dovetails at either 60 or 65 degrees, accounting for two of the most popular front dovetails.

All of their tools and products are well thought out and of the highest quality. I simply can’t recommend EGW enough if you’re an aspiring gunsmith or a seasoned professional.

For more info:

www.egwguns.com

Ph: (212) 538-1012