From the Bench:

A Bag-o-Gun …

Once the word gets out you can “fix guns sometimes,” people start to come out of the woodwork. I don’t mind helping out when I can, but the fact I sorta’ have a full-time job means I don’t have much spare time, especially when there are chores, pooches, tractors, mowers, trees needing cut, etc. — the typical stuff country folk are always in the middle of. But since I do enjoy a bit of what I call “hobby” gun work, I try to help out when I can.

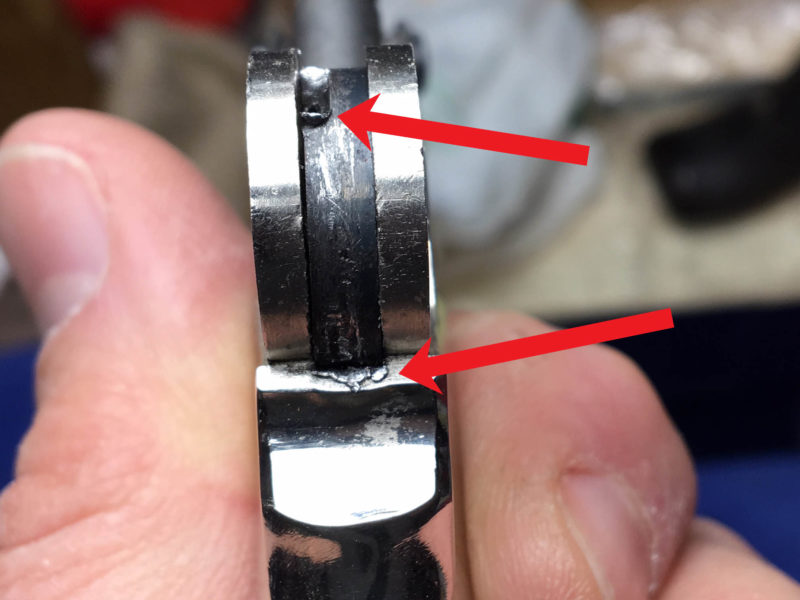

This latest came from a sort of “friend of a friend” who had “this old gun” needing fixed. Turns out it’s a family heirloom owned by his dad and he used to shoot it, decades before, with his dad. Over time, it sort of “fell apart” and it also looked like a string of gun mechanics tried to fix it. Between the broken parts and heavy-handed pry marks, it looked sad.

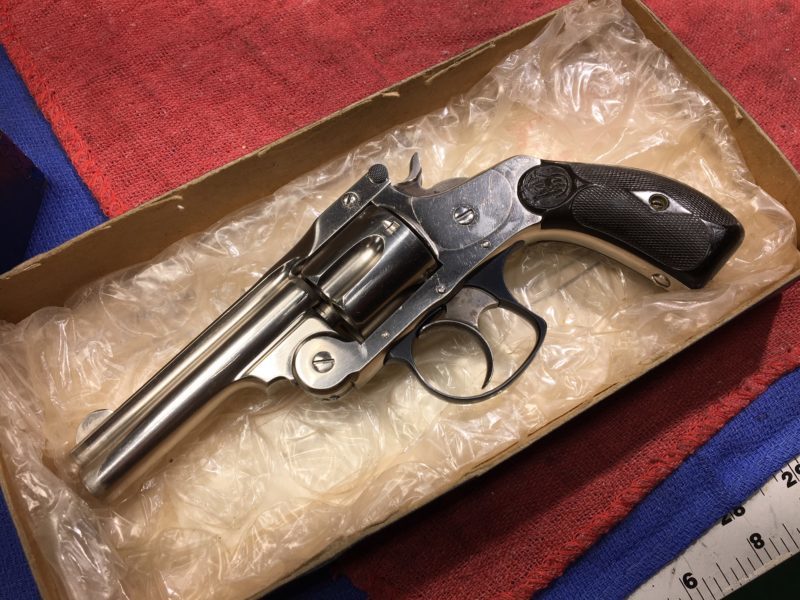

Arriving in pieces in a bag, I found out it was an early S&W DA revolver in .38 S&W, Third Model. I normally don’t mess with early top-breaks since they tend to be fragile, but being a Smith & Wesson meant it was of better quality and I did really want to get the gent’s gun back in business since it meant so much to him. “I’d just like to shoot it once or twice again to remember my dad, then put it away,” he said.

How could I say no?

On A Mission

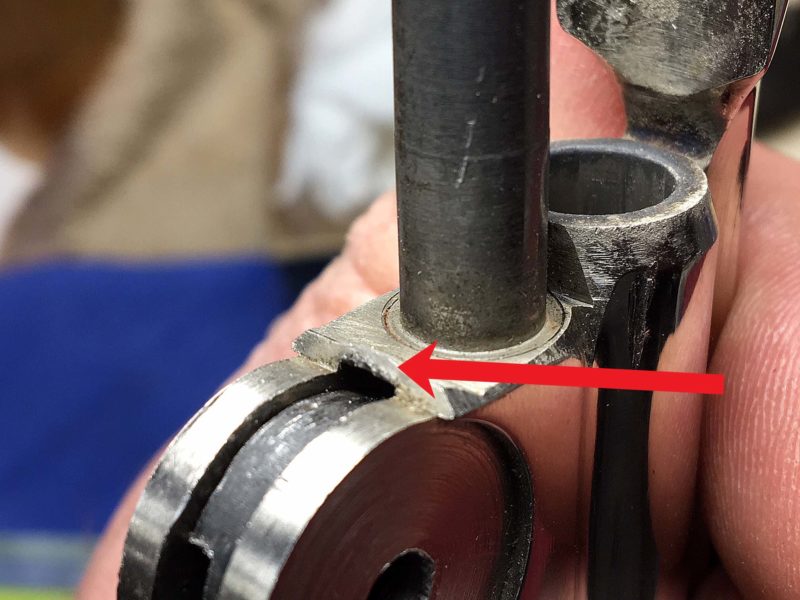

I did an inventory discovering what was missing or broken. The usual stuff like V-springs, sears, etc. were needed. I lucked out though, finding what I needed at Numrich. As is usually the case, these old parts come from used guns Numrich buys, and rarely fit as delivered. I had to TIG weld-up the DA sear and recut it, make a V-spring and generally repair the damage from the abuse the gun had survived in its life. But I got it running and I knew the owner would be awfully happy. I took a short video of the DA working at my bench, for the first time in something like 45 or 50 years. I have to admit it’s always satisfying to bring an old gun back to life.

I don’t charge for this sort of thing, as I like to do it, enjoy helping friends out and always learn something interesting. In this case, I was actually impressed by the quality of the Smith, and some clever engineering it had. I also counted my blessings yet again for the fact I have an extensive gun disassembly/assembly book library!

If I added up the hours I spent doing this little project — even if I had charged a good hourly rate — it would still be proof gunsmithing is often a good way to starve slowly!

Well — at least you get to buy tools … .