Extending An Encore Hammer Spur

Turning Awkward — Into Manageable

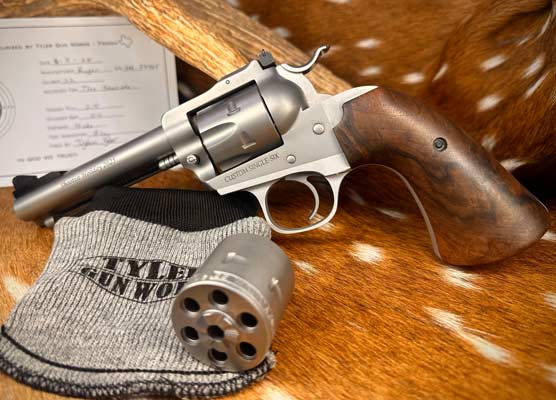

After finally finding a newer TC Encore in .308, I snapped it up, looking forward to testing it in my backyard range. I scoped it with a Crimson Trace rifle scope, promptly discovering even with the nifty TC Hammer Spur adjusted sideways, it was all but impossible to cock the hammer. Huh? What?

It seemed to me that would have been obvious at the factory level, but I think with S&W taking over the line some years ago and their general lack of interest in it, such things could happen. They have since closed down the TC brand, much to the dismay of fans everywhere. But I liked the idea of this stout receiver and .308 barrel, and the ability to swap barrels and calibers sweetens the deal. But I had to do something about that hammer spur situation.

The stock spur is secured to the top of the hammer with an Allen head screw. Where things went awry is the spur itself is simply too short, especially if you use a rifle-style scope with a lens bigger than an average pistol scope. Since these guns can shoot sub-1″ groups at 100 yards, I didn’t want to limit myself with a 2x pistol scope and a narrow field of view.

Eyeballing Things

I always start a new project by simply deciding what I want to be able to do with the gun when I am finished. That was easy … reach the hammer spur more easily to cock it. So how do I do that? Well, extending the existing hammer spur would work, but how? I thought about making a new spur using my milling machine, but then it dawned on me I could just shape a spur extension out of mild steel and TIG weld it to the existing spur. That takes advantage of the stock attachment bolt, making things much easier.

Digging into my metal cut-offs drawer, I found a small piece of steel about the right size. I band-sawed it into a rough shape, then TIG welded it to the existing hammer spur. It’s always just a bit scary to look at the rough part after being welded. It’s easy to think, oh Lord, I’ll never get that looking right. But there are few things I enjoy more than file work, so that’s just what I did.

After a half-hour or so, it started to look like I was going to win this war after all. I re-shaped the welded piece, blending it to the original spur, shaping the curve to clear my scope lens. When I had it roughed out, I installed it and found I had guessed right, and things were going to work out just fine. More hand-shaping, smoothing with various wet-or-dry grits and a final bead blast and I had a much better hammer spur in hand.

Final Finishing

rI was originally going to hand-checker the end of the spur for a better purchase with my thumb but spotted my skateboard tape stash. Skateboard tape is an awfully handy tool around the shop, and once applied to a pistol front strap, back strap, grip area or wherever, the term “non-slip” gets a new meaning. It works great, and the self-adhesive on the back of the tape really stays put. So, with a bit of tape and some trimming, I was almost there.

I used some touch-up cold blue to make things match the blued hammer and installed my final product. You can see from the photos it reaches past the circumference of the scope allowing me to get a good purchase on that spur for cocking. It changed the whole character of the gun and suddenly made shooting it fun rather than an ordeal with much fussing.

I’ve re-shaped hammer spurs on single-action revolvers, DA revolvers and even H&R Handi-Rifles, and it almost always makes the gun easier to handle and more pleasing to shoot. Keep that in mind if you’re confronted with a recalcitrant hammer spur “situation.”