Inside A Pistolsmith’s Brain

My Filing System

I respect my files; they’re indispensable in my shop. That’s why I take such great care of them. Most people would just say “meh.” But any machinist, tool and die maker will tell you that files can be as vital to a project as any tool or cutter.

Some of my files I’ve had for over 10 years. There are a few reasons they can last long. One is I keep them clean; this keeps them sharp. In my shop, files cut in only one direction, which is the right way. When I was in junior high, my shop teacher, Mr. Woods, would not let us near a machine until we mastered the use of hand tools like the file. I learned to chalk each file to prevent chip loading and how to clean the file and prevent rust. Today, a good Italian-made file like Grobet or U.S.-made Nicholson can run close to $50, more if it’s custom like a checkering file. I must have 50 files in all shapes and sizes, as well as tooth patterns.

For pistol work, I use them for opening up a sight dovetail, cutting a thousandth, cutting a part to fit a project, or checkering. Using a file effectively takes practice. One tip is to use either chalk or soapstone to fill the file’s grooves. This prevents material from sticking to the file, particularly with soft non-ferrous metals like aluminum, brass and gold. Once used, I card my files clean with a brass brush, then oil them to prevent rust. I store my files individually so they won’t nick each other.

Back To The Future

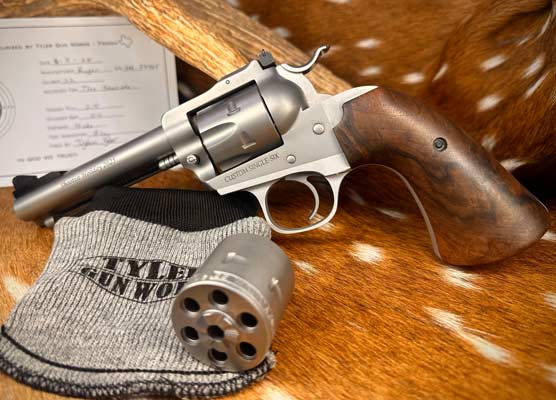

Sometimes I feel lucky to work on “relics” other ’smiths turn away. Not that they’re rust buckets, it’s just that they were built at a time many younger ’smiths can’t appreciate. Guns built by Giles, Shockey, Kart, Clark and King always seem to find a way to my bench. I’m amazed at the work these ’smiths, among others, did before I was born — and with little in the way of today’s machinery and welding equipment. Some of the innovation is used today by manufacturers with little or no recognition or credit.

I had an early Clark 1911 on the bench last week. This gun was converted from .38 Super to .38 Special for NRA Bullseye competitions. It was done in 1952. The barrel was bored out of the lug/chamber area and sleeved with a new bore. A small feed ramp was silver soldered into the frame, which was set in a pocket on the bottom of the barrel. This method later showed up in the Colt Mid-Range NM production guns. John Giles made lightweight hammers from factory pieces to reduce “lock time.” Shockey made these really oversized barrel bushings in an effort to minimize tolerances for more accuracy. The Giles barrel positioning tabs are welded into the slide for better lock-up.

And just when I think I’ve seen it all, something new shows up, like a unique slide-locking system by Giles that orients the slide to the frame at the front of the dust cover area. I think this is for consistent lock-up. Much of this work looks odd and out of place, but it was about accuracy, not looks. Building a gun that wins national championships was the goal, looks were secondary.

A Splash Of Added Color

Unique is good. In handguns, it’s usually the grips getting the unique treatment. Why not add some color to spice up your range gun? For a while, some of the top aftermarket parts manufacturers have added colors to their line of parts. Apex Tactical has had S&W M&P triggers in red, purple and blue for a while. Now, CZ offers the Shadow Model CZ75 with orange or blue grips and mag base pads.

With the popularity of the Springfield Armory Prodigy, Evolution Gun Works has jumped into the color game. They are offering limited “sprint” runs of magwells for the platform in blue and soon, other colors. The magwell simply slips on the polymer frame and attaches with a newly provided mainspring housing pin. I’m sure colored magazine base pads are in the works somewhere. It’s only a matter of time before whole guns are manufactured in bright colors, kinda like ’70s vintage cars. But remember, like a tuxedo, black never goes out of style.

For more info: MSCDirect.com (Nicholson files), EGWGuns.com (Prodigy Magwells), Brownells.com (checkering files)