“The Fixer”

Roy Huntington Flexes His Superpowers

Have no fear, The Fixer is here. Faster than a speeding bullet when editing mush, more powerful than a prepositional phrase, able to leap backlogs of pending articles in a single bound, it’s his Editorship, Roy Huntington.

Few people know mild-mannered Special Projects Editor Roy is a superhero of sorts. Sure, you’re familiar with his Super Editor Status when he was editor of American Handgunner and GUNS Magazine, simultaneously at times, mind you. But now that he’s the special projects editor, he has a little more time to hone his other superpowers in between making cool videos and writing feature articles with his turbo-charged Word program.

Working in the confines of his garage and/or machine shop, Roy taps into these other powers, transforming into his alter-ego, “part-time gunsmith guy.”

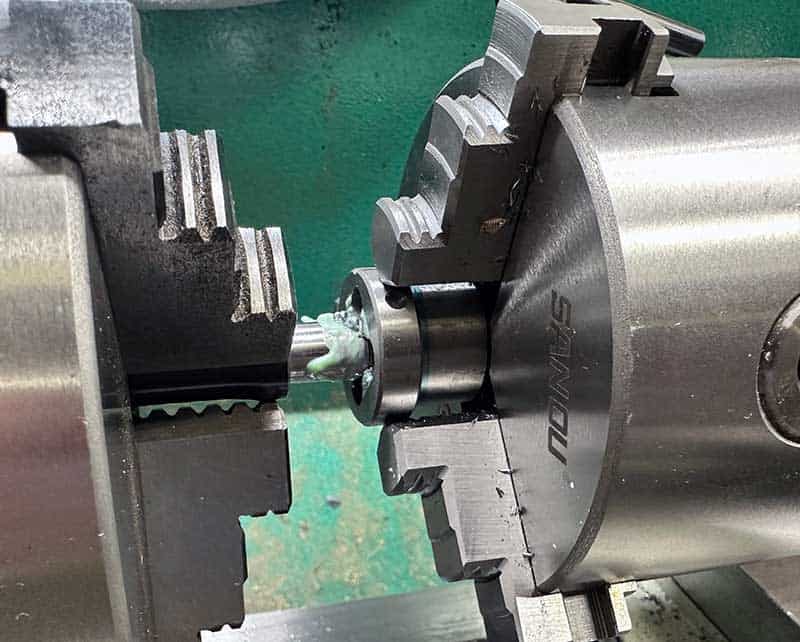

Roy’s got mills, lathes, drill presses, hammers and files to complete his “gunsmithy” projects. You’ve seen several examples of his work in the pages of Handgunner.

Tank’s Turn

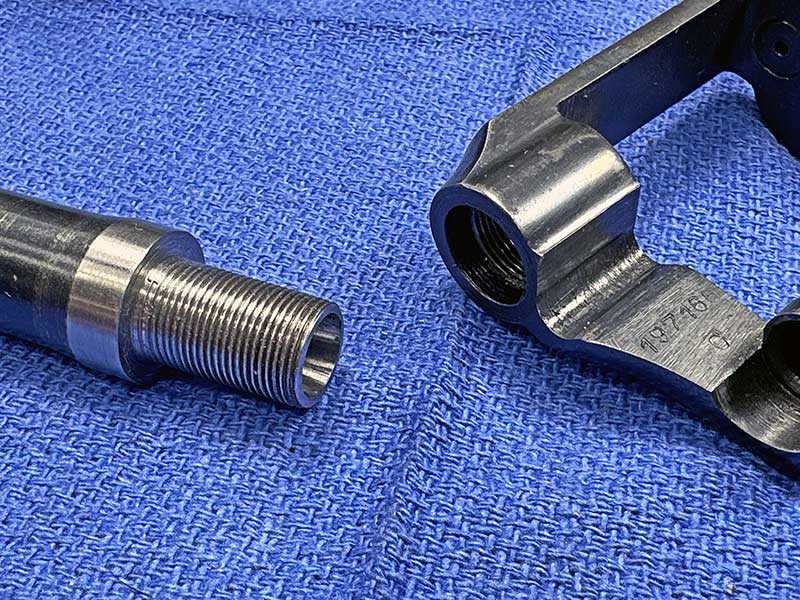

It just so happened I had a project for our superhero. I’d obtained a Colt Police Positive in .32 Colt for a song, but there was a problem. The thin forcing cone was split. I ordered a heavier replacement barrel from eBay, one having a thicker front sight I’d actually be able to see.

But there was another problem. The thread pitch was different than the older barrel. No problemo! Enter — The Fixer. Roy was able to turn down the old threads and re-thread the barrel shank to fit my frame.

When screwing the new barrel on, the front sight didn’t align properly. Rather than turn the shoulder down on the lathe, he used a hammer to peen the shoulder just enough for a snug fit, aligning the front sight so it was perpendicular to the frame.

Then, another problem presented itself. Remember that nice thick front sight? While being easier to see, it was too thick for the grooved fixed “hog trough” rear sight. Roy was able to open it up on the mill, lickity-split.

Care-Free Custom

Now I’m the proud owner of a carefree custom pocket pistol, worked over by none other than Roy Huntington. It looks better with the heavier barrel and has a front sight I can actually see. But more importantly, it was fixed by The Fixer, making my gun more valuable to me because of who repaired it.

The new barreled gun’s thicker front sight nestles perfectly between the freshly cut rear sight notch, providing a wonderful sight picture. I’ll need to figure on a pet load and file the front sight down to correct the point of impact. I’m looking forward to doing it.

I’ve already got some loads and, of course, cast bullets to try out in the re-barreled shooter. I’ll let you know how it goes in another article. But in the meantime, let this be a lesson — it’s always good to know a “Fixer.”