“Tanker” Model?

Wasting no time, Ken lops off part of the barrel and crowns what’s left. Everyone assumes this is a 5-minute job, and I did too. The cutting was quick using a band saw, but the inverted crown takes time due to the setup of the Bridgeport milling machine.

Ken tucks the gun into a storage box for future work as he tells me I’ll see the finished product next year. Did Roy have anything to do with this? Hmmm …

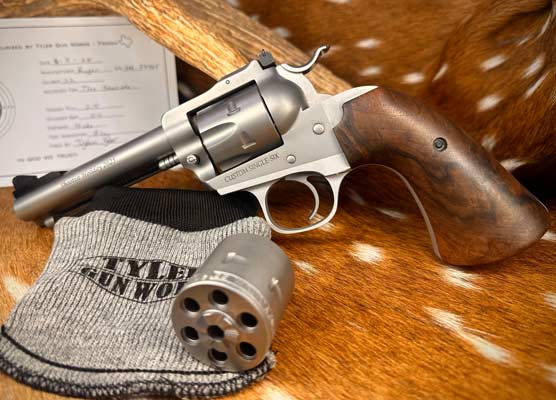

Fast forward a year and I’m back. The chopped-down GP100 is finished. Handing it to me, I’m in awe! Holding the perfect concealed carry revolver, with plenty of punch and polish, it only needs proper stocks, but I have an idea.