Precision tuned Steel!

Bradford knives takes the Guesswork out of knifemaking

There was a time when custom, handmade knives were considered the finest cutting knives in the land and, while the human touch is still highly revered in cutlery circles, modern CNC technology has become a fine art in itself. Around 25 years ago a noted custom knifemaker was in the process of shucking his custom label and switching to becoming a micro manufacturer — telling me his knives would become even better because he could hold tolerances he couldn’t achieve in his handmades. Chris Reeve Knives would become a full-blown force to be reckoned with in the cutlery industry and win Quality in Manufacturing awards year after year at the annual Blade Show. Since then, many top custom knifemakers have made CNC a part of their knifemaking diet.

Bradford Knives

Founded in 2011 by Brad and Nicole Larkin in Renton, Wash., this enterprising couple had a game plan and it didn’t include a lot of human touch. “There is very little handwork on our blades,” Brad tells Handgunner. “Almost everything is done in a machine shop environment. We consider ourselves a production knife manufacturer with many customizable options — like scales, grinds, and finishes — such that whatever knife you build, chances are there are not many in circulation exactly like what you have specified.”

The Larkins didn’t just jump into the knife business cold, however. Brad’s background in manufacturing and a flair for design served as the foundation for a sound start. Initially, the Larkins tested the cutlery waters with a simple culinary knife. “The Gatsby steak knife was a surprisingly popular first introduction, and we quickly pivoted to being a customer focused, customer driven cutlery business,” notes Brad. “Our next knife, the Guardian3, was developed based on customer feedback, realizing the industry was needing a compact EDC fixed blade built using premium materials and technology.”

Growing The Line

The release of the Guardian3 would portend bigger and better things to come. “The Guardian3 is still our flagship knife and most popular,” Larkin informs. “Known for its sub-compact design and ability to conceal carry, this fixed-blade is designed to replace your common folder. It’s small, lightweight, easy to draw and re-sheath, and once you wear this knife, it’s hard to imagine grabbing another one again.”

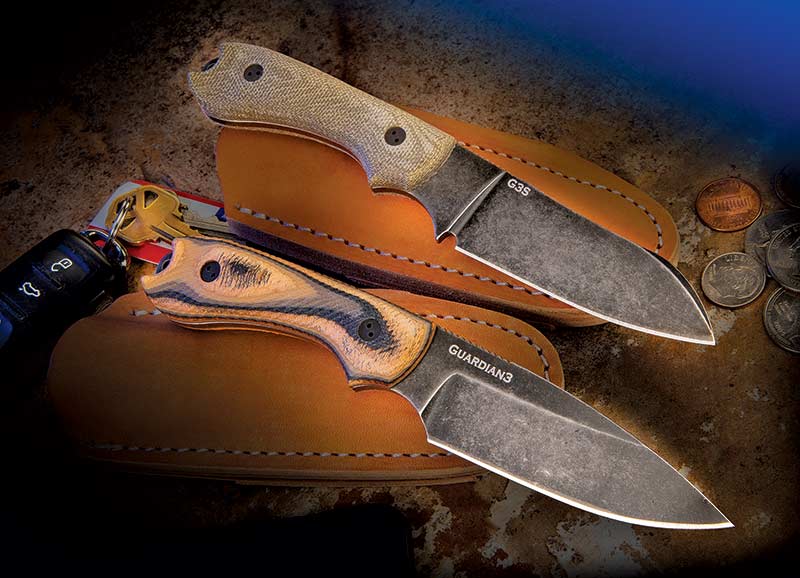

The Guardian3, checking in at 6.75″ overall with a 3.0″ drop-point blade, soon begat siblings in various lengths all the way up the Guardian6, which stretches out to 11.0″. Bradford also offers the Guardian3 in optional Wharncliffe and Sheepsfoot blade styles. “The Sheepsfoot G3S has been growing in popularity since its release,” Larkin relates. “This model was developed using the same popular scales and leather sheath system as our flagship Guardian3, however we incorporate a well-balanced Sheepsfoot style blade with an integrated finger choil guard for enhanced safety. The Sheepsfoot blade shape can work well in rescue situations, skinning and cleaning animals in addition to its primary role as a compact every day carry tool.”

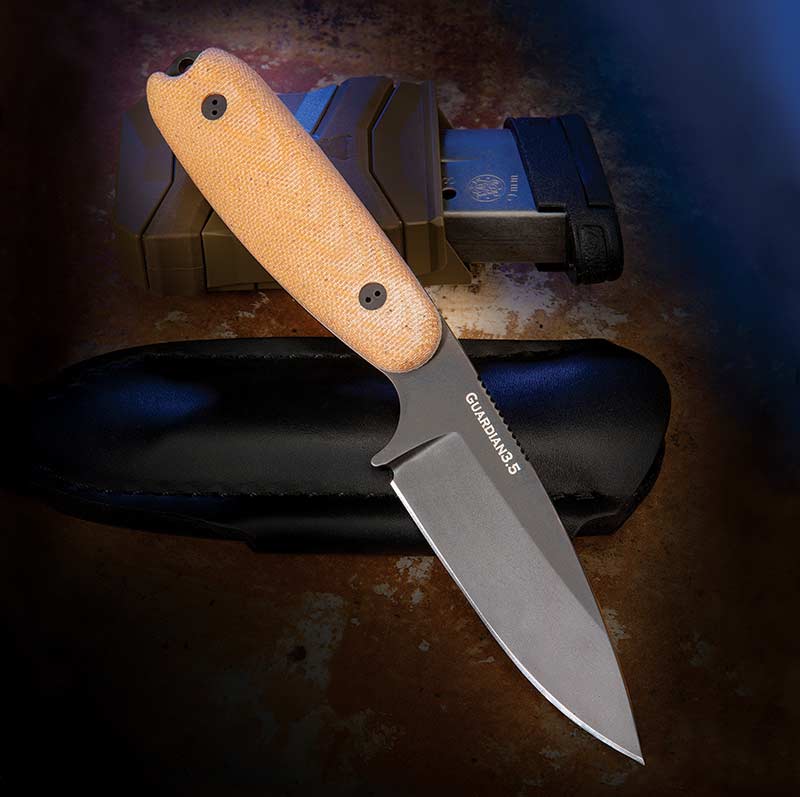

The Guardian3.5 adds a bit more length to the equation. “The G3.5 is an ideal EDC blade and a perfect size for horizontal, cross draw carry,” Brad conveys. “Also known as ‘scout’ carry, this method of carrying fixed blades is designed to take the work of your folding blades and be highly concealable at the same time. You can deploy the blade faster and easier than a typical folder and put the knife back in to its sheath easily at the waist.”

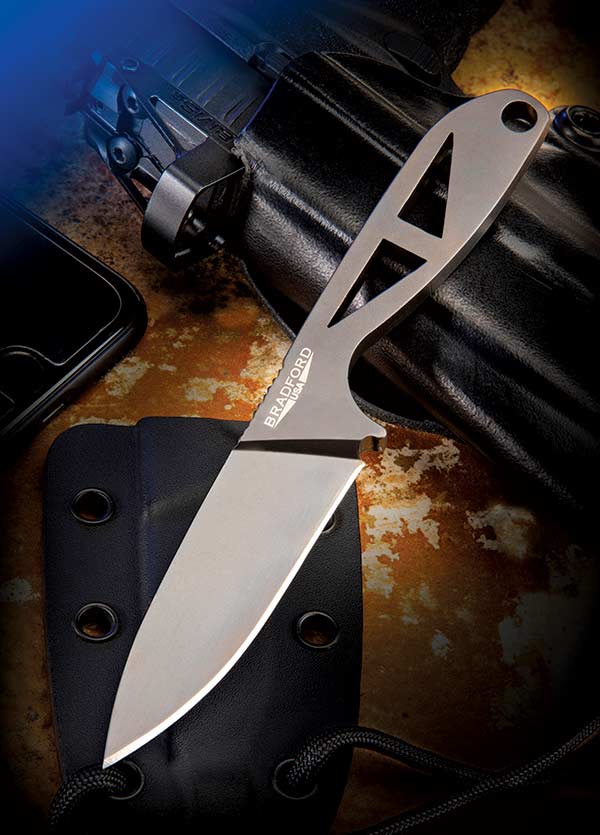

The fun doesn’t end with the Guardian series. “The G-Necker is a compact neck-style knife made out of premium Elmax steel — heavy stock designed to create a robust handle area without the need for additional scales,” Brad imparts. “It is carefully designed to give the user an excellent pinch grip purchase, great for fine cuts as well as emergency use.” By “robust” Larkin means one-quarter inch steel, a feature rarely seen in a neck knife. Having personally tested the G-Necker I can tell you, it’s a little beast.

Stepping up in size is a Guardian both bushcrafters and survivalists will enjoy. “The G5.5 is designed as a survival/bushcraft crossover,” Brad relays. “Incorporating some of the most important features for backwoods experts, this knife boasts CPM-3V steel and comes fitted with a high quality English bridle vertical carry leather sheath. This knife is great for an overnight camping trip or a week in the back country. There is not much the Guardian5.5 will shy away from.”

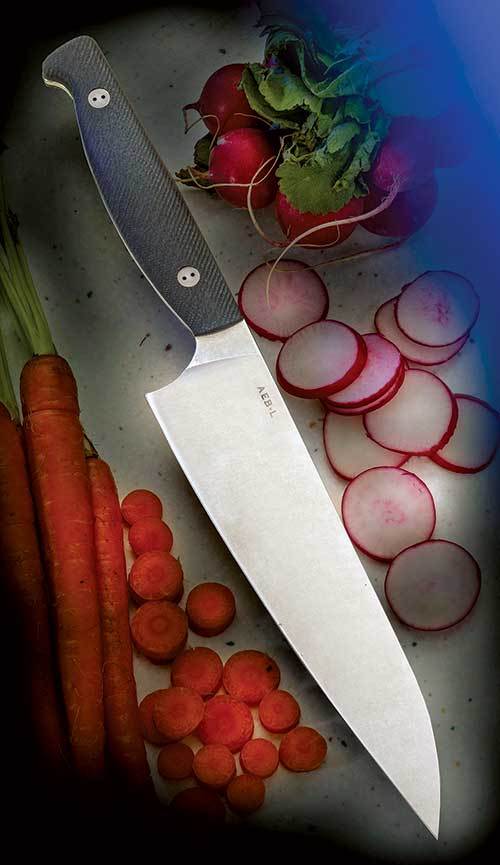

Finally, the Larkins added a welcome addition to their original steak knife with their Bradford Chef Knife. “This premium upscale kitchen knife was designed in close collaboration with some of the greatest local chefs in the Pacific Northwest,” boasts a proud Larkin. “The thin blade stock is somewhat rare in the culinary industry and allows for some of the finest cuts modern culinary tools can provide. The AEB-L steel is a kitchen favorite not only for its superior stainless properties but also its ability to hold a precise edge — and its ability to be sharpened relatively easily.”

Sheer Quality

Aside from versatile designs the Larkins offer all their knives in top shelf, proprietary steels and durable handle scales. “We use a variety of different steels and pride ourselves on being application specific,” Brad explains. “Simply put, we choose the best materials for the job. Our favorite EDC steel is M390 stainless, and our favorite outdoor steel is CPM-3V stainless. Handle materials can vary but Carbon Fiber remains a favorite as well as popular colors of G10 and Micarta.” Add this to the ability to pick from a veritable cornucopia of handle materials from plain to fancy and Bradford customers can have a field day designing their own personal cutter.

“Our customers are users and collectors,” Larkin notes. “They appreciate quality materials, quality manufacturing and U.S.A. pride! We try to continually innovate but we are not creating a new knife every month, rather curating a collection of unique steels matched with some of our tried-and-true favorite models of absolute workhorses of knives.” Asked about the company’s future plans Brad simply states, “We will continue to push the envelope of manufacturing and quality, focus on customer satisfaction and be driven by their uses and applications.” Having given several of Bradford’s precision tuned factory knives a workout I can attest you’d be hard to find anything that cuts any better.

For more info: BradfordKnives.com