Exclusive: Handloading

+P Brass

Case Capacity And Pressure — Does It Matter?

Some back-story first. Plus P (+P) brass is designed to be stronger than regular brass in order to withstand the additional pressure of +P rated cartridges. Some handgun cartridges have a higher pressure variant of the standard cartridge. These include 9mm Luger, .38 Special and .45 Automatic. The additional pressure increases velocity to enhance bullet terminal performance, generally for use in personal defense. The increased velocity has more energy and helps to ensure the expansion of expanding bullets (e.g. hollow point, soft point) or deeper penetration with non-expanding bullets.

The .38 Super is also labeled +P, but technically there is no “standard” .38 Super in the USA without the +P name. The Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) only recognizes the .38 Automatic and the .38 Super Automatic +P (which we often just call .38 Super). The +P designation was added to the .38 Super Automatic name in 1974 (according to the Speer loading manual) to help distinguish the high pressure .38 Super Automatic from the old low pressure .38 Automatic cartridge. These two rounds share identical external dimensions but have very different operating pressures, and it would be dangerous to fire .38 Super Automatic ammunition in the older guns chambered for the .38 Automatic, hence the +P name.

Stronger Brass?

In some semi-automatic pistols, the feed ramp consists of a slight cutout of the barrel chamber which might leave some portion of the case above the extractor groove exposed, or unsupported. This unsupported part of the case can expand when the cartridge is fired, and if the brass is not strong enough to hold the pressure, the case can burst, which can damage the gun and injure the shooter and bystanders. It’s important to ensure the case is strong enough at this unsupported portion to contain the pressure, so +P brass is often thicker and stronger here. Brass is usually made stronger by thickening the web and case wall near the base.

Brass can also be made stronger by altering the grain structure and heat treatment, according to Starline (part of their description of .45 Super cases).

A thicker web and case walls reduce internal volume, and this in itself will increase pressure and velocity since the powder chamber is smaller. Some +P brass does have reduced volume, but some +P cases might not have less volume than standard cases. It could depend on who makes the cases, because their “standard” pressure brass might be strong enough for +P pressures. In this instance, all they have to do is add +P to the headstamp.

Starline makes +P pistol brass fitting both of these descriptions. Their 9mm Luger +P and .38 Special +P cases are identical to their regular cases. The only difference is the headstamp, because their standard case design will handle +P pressures, according to the description at their website. On the other hand, Starline’s .45 Auto +P brass has a thicker web and heavier sidewall at the base, and has approximately two grains less internal water capacity than their standard cases.

The capacity difference of new Starline .45 Auto cases was measured by filling them with Accurate #7, a fine grained powder. The standard .45 Auto case held 29.1 grains, and the +P case held 27.6 grains. That 1.5 grain difference translates into a 5.4 percent capacity difference.

Starline’s .45 Automatic standard and +P cases were used for this comparison of the effects of case volume on pressure and velocity.

The Numbers

When you add a bullet to the case, the capacity ratio difference becomes even larger because the bullet will fill the same volume in both cases. For example, if the bullet fills 30 percent of the standard case, it will fill 32 percent of the +P case because it has less capacity to start with. And the difference becomes greater if the bullet fills more of the case, as when a bullet is seated more deeply. There will be a greater rise in pressure in the +P cases than in the standard cases as a bullet is seated deeper.

There’s separate load data for +P loads published in some loading manuals. Western Powders provides +P data for 9mm Luger, .38 Special and .45 Automatic. They appear to use the same case for the standard and +P data in the 9mm Luger and .45 Automatic. That is, they do not specify a +P case for the +P data, so presumably, the case capacity is the same. They use different brands of cases for their .38 Special standard and +P data, so it’s not known if they might have the same capacity or not. In any event, their +P data uses more gunpowder when using the same bullet.

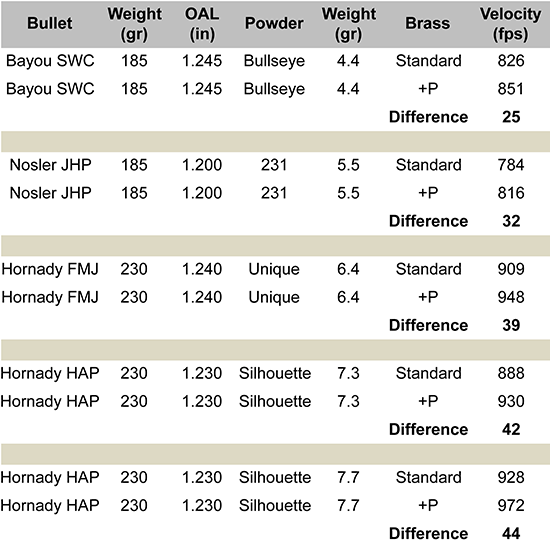

I tested the effect of the thicker-walled +P cases on velocity by loading the same charge weight in new Starline standard and +P .45 Auto brass. Four different gunpowders were used: Bullseye, 231, Unique and Silhouette and 185 and 230 grain bullets.

Since the reduced capacity of the +P cases should produce an increase in velocity when they are loaded with the same charge weight as a standard case, another question is whether this increase in velocity would be similar to using the larger +P powder charge weight in standard cases. For this comparison I used Western Powders’ data for Ramshot Silhouette and a 230-grain Hornady XTP loaded at 1.210″ OAL. I substituted the bullet with a Hornady 230-grain HAP loaded to 1.230″ OAL, and used Remington primers instead of Federal.

Many of Western Powders’ maximum .45 Auto load data is close to this cartridge’s SAAMI maximum pressure limit. The SAAMI pressure limit is 21,000 psi for the standard .45 Auto and 23,000 psi for +P version, a difference of 2,000 psi.

Western Powders shows the maximum standard load of 7.3 grains of Silhouette for the 230 grain bullet produced 20,867 psi, and the maximum +P load of 7.7 grains of Silhouette produced 22,968 psi, an increase of 2,101 psi. The maximum standard charge and the maximum +P charge were both loaded in Starline standard and +P cases.

Fifteen rounds were loaded with each charge weight/bullet/case. The ammunition was fired from a 1911 .45 caliber pistol with a 5” Kart barrel.

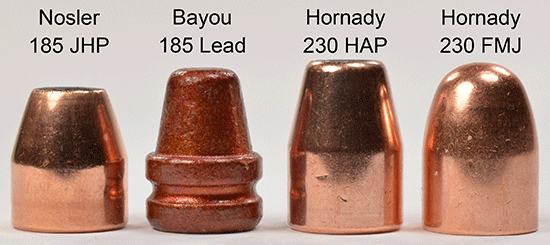

Bullets used for this comparison included jacketed Nosler and Hornady bullets, and a polymer coated cast lead Bayou bullet.

Velocities

In every instance when the same amount of powder was used in standard and +P Starline cases with the same bullet, the velocity was higher in the +P cases. The velocity increase ranged from 25 to 44 fps depending on the powder and bullet. A quick statistical analysis with Student’s t-tests showed every example of increased velocity was statistically significantly higher (probability less than 0.001).

Western Powders recorded a 47 fps increase in velocity when they increased the maximum standard load of Silhouette by 0.4 grains for their +P load in the same cases. My results showed a 42 fps increase using the same charge weight in standard and +P cases.

The average velocity of the maximum standard pressure load with Silhouette in the +P brass was 930 fps. This was two fps faster than the 928 fps produced by the maximum pressure +P load in the standard brass. Therefore, in this comparison, simply putting the standard pressure load in the +P case increased velocity to a slightly higher speed than using the increased +P charge weight in the standard case.

One precautionary note pertains to putting a +P charge in +P cases. If the +P case has less volume, it will increase pressure and velocity even more than it would if placed in a standard case. In this comparison, the +P charge weight in the +P Starline brass produced an average speed increase of 84 fps over the standard max charge in standard brass. It’s hard to say how much pressure might have increased in this situation, but it’s probably more than the pressure increase seen in Western Powders’ data.

Load parameters and velocity for the ammunition used in this comparison. Velocity was recorded with a Shooting Chrony chronograph at about 10 feet.

Does It Matter?

Whatever cases you use, if you’re dabbling with +P loads, be sure to follow the general rules of load development. Work your loads up in your gun to make sure they are safe, and watch closely for pressure signs. Even the strongest brass has limitations.

Different brands of cases might have different capacities. The capacity of two other brands of new .45 Auto cases was measured, standard Winchester and Remington +P. The Winchester case held 28.3 grains of Accurate #7, and the Remington +P held 27.9 grains. These values are in-between the weight that the two types of Starline cases held.

These results provide a nice demonstration of how case capacity can affect velocity. Less case capacity increases velocity and pressure. For most of our general shooting, small changes in case capacity probably don’t make much difference, but if you use mixed headstamp brass, there is a good chance the velocity will be more variable than if the cases are all the same headstamp. If you want the most consistent speeds, use the same headstamp.

If you’re loading +P loads, it’s wise to use +P brass because this identifies it as being strong enough for the task. An advantage of Starline’s +P .45 Auto cases, in addition to being strong, is they might not require much, if any, additional gunpowder to achieve a +P velocity, and probably +P pressure, too.