Mighty Sparta!

Spartan Blades Continues Its March

Through The Tactical Battlefield

The old proverb “The road to Hell is paved with good intentions” applies to all industries, cutlery included. Many try — many die. Spartan Blades LLC is the exception to the rule. Back in 2008, Spartan Blades was the vision of two Army Special Forces veterans looking for a livelihood after their service to our country. Co-owners Curtis Lovito and Mark Carey walked up to the door of the cutlery industry, kicked its ass, and took names. Their reputation among the Spec Ops community and a bevy of rock solid knife designs set Spartan Blades on the right course from the get-go and they’ve never looked back.

What road to Hell?

Eight years later Curtis Lovito reflects on the reasons for the company’s success and endurance. “A lot of hard work and planning,” Curtis explains. “We try hard every day to make quality knives our customers want and provide great customer service. We also feel it is important to identify what you’re not good at and reach out for help. It’s like they told us as young troopers in the Infantry ‘Know yourself and seek self-improvement’.”

“Our growth was exponential in the first few years despite a terrible economy in 2008–10,” Mark Carey adds. “We still do small batch production, 50 to 100 knives of a model at a time. In the beginning it was just 30 to 50 knives. We really have tried hard to control our growth and continue to maintain and increase our quality. We get paid now, which was not the case for the first two years, so that is the biggest change!”

From day one Spartan’s blades were top shelf. Lovito and Carey chose excellence over quantity and they constantly ride herd on quality control. “We have systems in place for redundant checks throughout our processes,” notes Curtis. “Just like when we were NCO’s in the Army, we check at least twice to insure our knives are ready to move on through each phase of production. As we have hired employees — we now have six people working, including ourselves — we have instilled in them they can stop a process if it is not right and we come together to fix an issue before moving on through a process. We take pride in our work and product!”

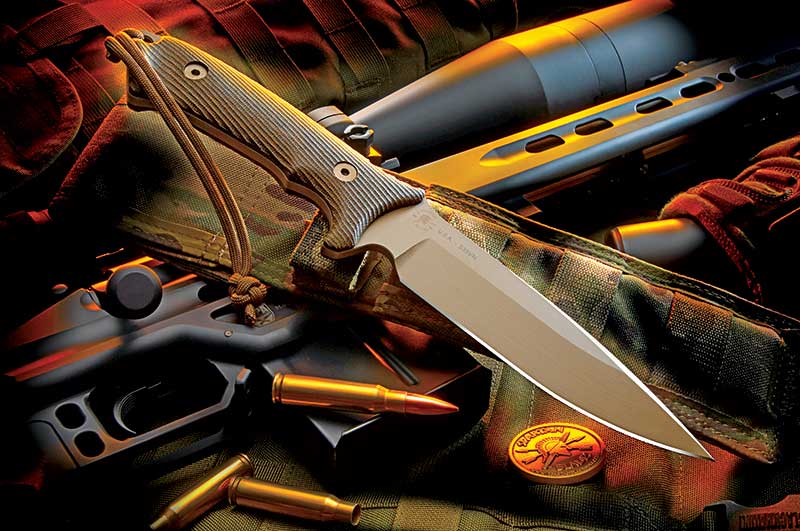

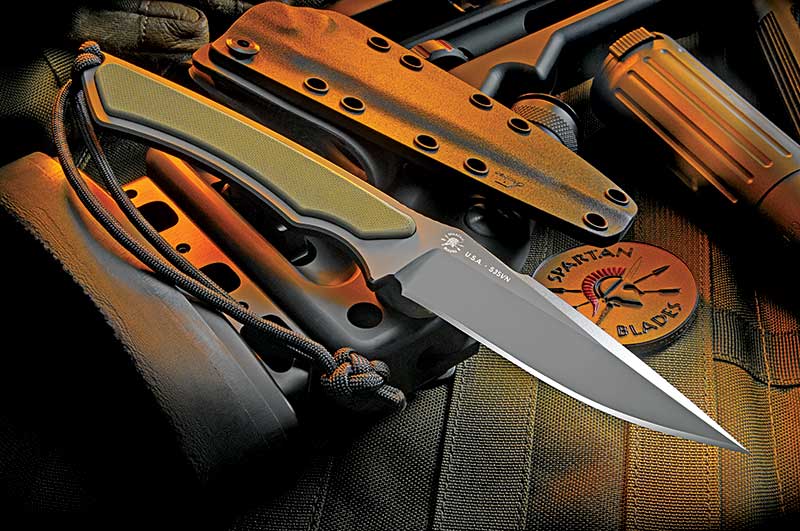

Using the right — and best — steel and handle materials is every bit as important to Curtis and Mark. Carey notes, “We started making all our fixed-blades with S30V, but changed to S35VN when it came out five years ago as it is the best overall blade steel in our opinion for most knife designs. We use 154CM for our CQB tool as it springs (more ductile) better for its purpose. We use 20CV on our lapel dagger as it has high chrome and we thought it needed better corrosion resistance. All the rest of our line of eight other fixed blades use CPM S35VN as it is the best balance of excellent edge retention, corrosion resistance and toughness. We use canvas Micarta handle scales on the majority of our fixed blades as it has great grip dry or wet. We use G10 on our V14 dagger and Phrike models. We use only CPM S35VN on our folding blades as we think it is the best overall US-made blade steel for a folding knife.”

From Fixers To Folders

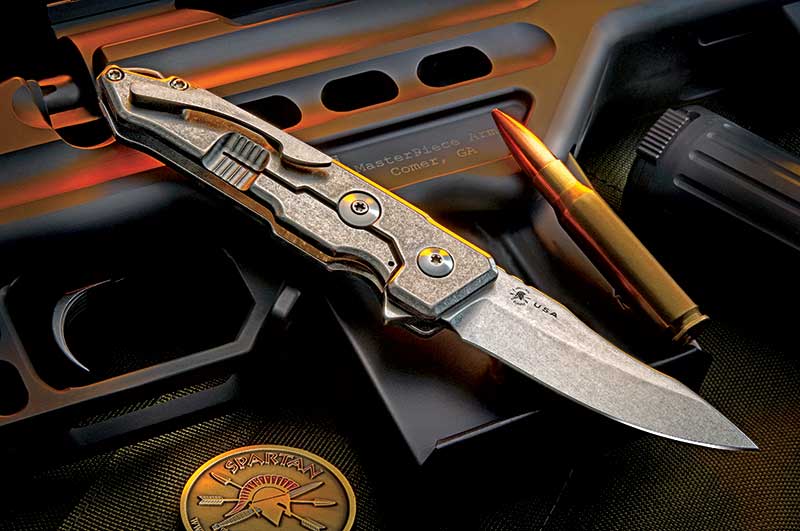

Spartan Blades’ initial offerings were all fixed-blade knives. “We started with fixed blades because our experience was with them and we saw a need for knives that met modern soldiers’ current load and equipment,” Carey recounts. “We worked on our first folder, the Akribis, for almost two and a half years in prototyping and testing before going into production. We learned a lot from that knife! The Pallas is a folder Curtis designed. Our intent was to make a soldier-friendly knife for a more affordable price, so it has a button lock action with caged bearing pivot which allows a soldier to open and close the knife with a gloved hand.

“At the 2018 SHOT Show we introduced our fourth folder, the Metis,” continues Mark. “This is a nice clean gentleman’s flipper-opening frame-lock with a caged bearing pivot. The frame is titanium and it has a CPM S35VN blade. Our fifth and newest folding knife is the Spartan Harsey Folder (SHF). It is a William Harsey design and it just won our fourth Blade award for Best American Made Knife at the 2016 Blade show. We are very happy and surprised at the rapid attention this design has received as we only introduced it at SHOT show 2016 as a prototype. We had many pre-orders and our SHF production has been growing steadily ever since. We will soon be doing more custom and limited offerings in Chad Nichols Damascus of both the Metis and SHF.”

The Harsey Effect

Custom knifemaker William “Bill” Harsey is a legend in the tactical cutlery community who has collaborated with some of the best companies in the industry. “When we started out we contacted Bill Harsey and Chris Reeve for advice,” Curtis notes. “Both of the Reeves, Chris and Anne, were very welcoming and gave us great advice for our start up. We visited them and became friends over the first couple years. Bill liked what we were doing and offered to collaborate on a design.”

“We were in his shop brainstorming when he pulled out a set of handles he’d made for Col. Rex Applegate in the early 1980’s. They looked awesome and were very ergonomic. Bill designed a blade to go with them and the Spartan Harsey Model I was born — and we won the BLADE Best collaboration of 2010 with it.”

“Bill’s designs are iconic as he is a very experienced and talented artist/knife maker,” Mark adds. “He has a long history of great knife designs he has done with Al Mar, Col. Applegate, Gerber, Chris Reeve, Boker and others. His large jimping, handle designs and blade styles are popular and easily recognizable. He is a pleasure to work with and we know his designs will function as intended. In 2012 a Canadian Special Operations unit contacted Bill and us. From that meeting — and working with them to meet their needs —the Difensa fixed-blade was born. We are friends with Bill first, as well as business partners, but we truly have learned a lot and done well together.”

Future Spartans

Firmly entrenched in the world of tactical cutlery, we asked Curtis where Spartan Blades goes from here. “We will continue to learn, broaden our models and knife types,” states Curtis. “We are working on some new folders, a couple more collaborations. We just bought a fiber laser so we will be doing some special editions embellished with 2D and 3D engraving. We continue to listen to our customers and design knives they want, and we want to make. We are having fun and making good tools for users and collectors.” The march continues!