Send In The Clones

Ready To Take The '80 Percent' Challenge?

An 80 percent pistol build such as a Polymer80 project is not a money-saving alternative to buying a new pistol. It will cost you more, but that’s not the point. The win is in building your own handgun and the satisfaction coming from a job well done.

For dedicated handgunners the workbench is more than a place to develop the latest handload recipe or to clean firearms to within an inch of their lives. This is the altar of the sacred, almost mystical gun cave — the patina platform of spilled oil, cleaning solvent, tool marks, and sweat — where fantasies of butter-smooth trigger jobs and performance modifications come to life.

Rarely though is the workbench host to more than handgun tweaking, refinishing, or minor modifications. As they say in the drag racing world, “You run what you brung.” In most of our situations, this means we “Work with what we got.” In other words — factory shooters.

Recently, the call to build a handgun from collected parts has rung loudly in our ears. Having built numerous AR-15 rifles and AKMs from carefully selected parts and 80 percent receivers, the lure to see what all the noise was about regarding 80 percent pistol builds was too much to resist. We investigated, we bought, and we built. The results proved, um … interesting.

More on this in a moment. But first, if you’re new to the DIY firearm world, a short primer on the “ghost gun” movement is in order.

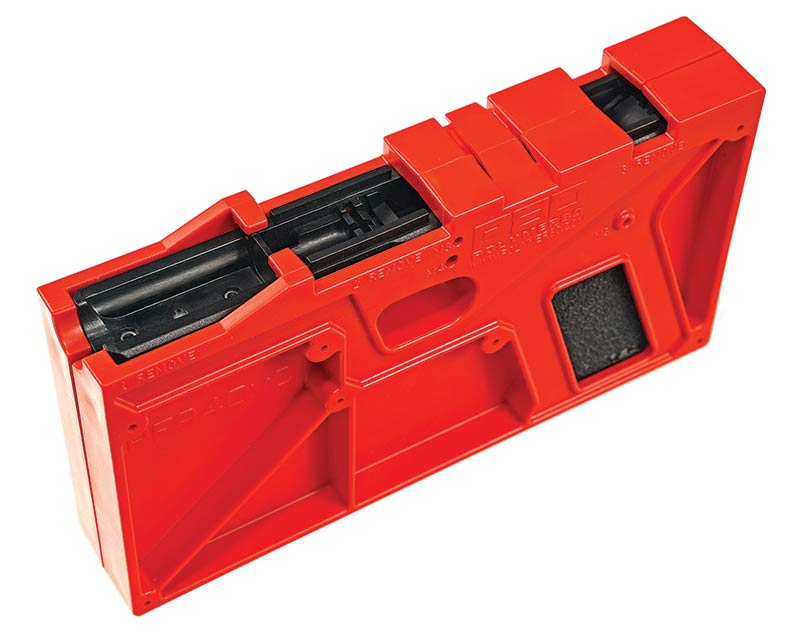

The Polymer80 Standard Pistol Frame Kit (model PF940v2 shown) includes the 80 percent receiver, jig, locking block rail system, drop-in rear rail module and everything you need in preparation for GLOCK components.

The frame sandwiches between the one-time-use-only jig. Slots along the rail and the pin holes along the sides offer drill bit and end mill guidance.

Entrepreneurs

With the advances in CNC machining and polymer molding technologies, forward-thinking gun folks figured this somewhat lenient posture by the BATFE opened opportunities for supplying 80 percent receivers to the firearm DIY enthusiast market. By including some instructions, a jig, and a few cutting tools along with an 80 percent completed receiver, a guy or gal could build their own gun.

As mentioned, 80 percent builds are common among the AR and AK crowds, but only recently has momentum been building on the handgun front. Compared to the black rifle market, the 80 percent handgun scene is miniscule, with only two primary manufacturers leading the way: Stealth Arms and Polymer80. The former specializes in the 1911 platform while the latter concentrates on frames accepting GLOCK hardware.

Since the Polymer80/GLOCK-style platform is the more pedestrian — and lower cost choice — for those ready to take a shot at building their own pistol, we decided to go that route and see just how easy or difficult this would be for the first-time builder. Our choice was the Polymer80 PF940v2 Standard.

The Polymer80 Pistol Frame Kit comes with the basics needed to prepare the 80 percent polymer receiver to accept all necessary GLOCK components. The kit includes the frame, a two-piece jig, 3mm drill bit (for the locking block and trigger housing pin holes), 4mm bit (for the trigger pin hole), large end mill (for the barrel block and excess frame material), locking block rail system, rail module and the necessary dowel pins.

While the Polymer80 kit comes with the specialized equipment and parts needed to complete the receiver portion of the build, a brace of basic shop tools and some gunsmithing supplies are also required. Although a milling machine is the optimal choice for the requisite drilling and milling, we experienced no problems performing the work on a drill press fitted with a cross-slide vice, which is recommended.

Although work on a milling machine is optimal, most home shop builders will only have access to a small drill press. Careful alignment, secure clamping to a solid base, and a take-it easy approach will get the job done nicely.

A supplied end mill is used to remove excess material from the interior barrel block and along the top rails.

Easy Mods

As it turned out, the modifications required to prepare the Polymer80 receiver for final assembly was less than we had anticipated. Only three sets of pin holes needed to be drilled. One to accept the trigger retainer pin, one for the trigger housing retainer pin and one for the locking block rail system. Milling operations were limited to cutting down the raised material along the top rail — sections at the locking block rail system and at the rear rail module — and milling out the barrel block.

Once we set up our drill press and fashioned a wooden, vise-mounted base ensuring a solid platform for drilling the pin holes, the receiver completion process proved simple and straightforward. By following machining “best practices” — or as best we could when using a home-shop drill press instead of a milling machine — and the provided instructions, we had the receiver drill and mill work finished in no time flat. With the machine work done, final finish was accomplished by smoothing out the mill work with a selection of flat and half-round bastard files along with some 320-grit aluminum oxide paper.

Assembling the Polymer80 pistol caught us somewhat by surprise. Having enjoyed more than our share of aftermarket-style products making such claims as “drop-in fit” or “E-Z bolt-on” — yet often requiring sledgehammer force, torching, and long strings of colorful metaphors to make work — we were expecting challenges when it came time to install our new GLOCK components. Shockingly, this didn’t happen. Polymer80 did an excellent job of producing a receiver with exceptionally precise dimensions. Everything went in where it should, as it should.

In the end, it was basic GLOCK armorer-level work required to finish assembling the Polymer80 pistol. Of course, we added a bit of fun stuff along the way. Nothing overt, mind you. Just a couple of tried-and-true mods such as trigger mechanism polishing and the addition of a 3.5-lb. connector to ensure the new build would run velvety-smooth.

Once the framework and final finish/sanding has been completed and the locking block rail system and drop-in rear rail module have been installed, the rest is basic GLOCK armorer-level assembly processes.

The Mechanics

After gauging headspace, performing a comprehensive bench-test of the trigger, testing the three safety features found within the GLOCK pistol design, and conducting a function-check, we were off to the range to see how our DIY project would hold up to live fire. Test round #1 went off without a hitch, as did subsequent rounds fired. There was no deformation of the fired cases and firing pin protrusion was spot on. With confidence nothing threatened to come apart at the proverbial seams, we moved on to rapid-fire mag dumps, where our hybridized clone performed on par with our factory GLOCKs. No failures to feed, extract, eject, or to fire were noted.

From a purely operational standpoint, the Polymer80/GLOCK clone ran flawlessly.

Now with the mechanicals settled, let’s talk about ergonomics and handling.

Obviously, a receiver built to accept GLOCK hardware is going to stick close to the factory GLOCK profile. Components, after all, must be interchangeable, so any radical reinterpretation of the GLOCK form is a no-go. This said, the Polymer80 frame has its own unique characteristics.

Up front, the Polymer80 sports an integrated 2.25″ Picatinny/STANAG-compliant accessory rail. Moving rearward, the leading edge of the trigger guard has a double contour with a serrated groove too narrow and too sharp-edged for our comfort. We’ll take the broader GLOCK-style trigger guard face any day. Farther back on the trigger guard, the Polymer80 earns a plus with its more generous groove. In our book, it’s much more comfortable than the GLOCK design. The Polymer80 trigger guard opening is also a skosh larger than the G17 Gen 3 we had on hand to compare — 0.965″ versus 0.922″, respectively. Not much, but enough to make a comfortable difference.

The business end of the receiver is where we found the greatest separation between the Polymer80 and the GLOCK. The former has a straight-grip design with perfectly flat side panels, back strap and front strap. The latter features finger grooves and 360-contouring. We weren’t sure we’d like the Polymer80’s bread-and-water profile, but once we wrapped our mitts around the grip, such notions quickly fell away. Add in the surprisingly sticky stippling generously apportioned along the grip and any doubts as to the practical nature of this pistol chassis soon disappear.

Another difference is found along the beavertail. The GLOCK, of course, doesn’t have much going on here — the Polymer80 does. The grip continues its contour up to the level of the slide rail, offering a less crowded feel between the index finger and thumb. It’s another design element large-handed and gloved shooters will appreciate.

An 80 percent project is the perfect opportunity to build a GLOCK-style pistol your own way. For this build, we opted for a Swenson slide, 3.5-lb. connector, and front/rear Tritium sights. Additionally, we polished the trigger assembly contact points for smoother operation.

And?

There are no disappointments from this corner of the peanut gallery. It’s a solid platform that, from our experience, will stand toe-to-toe with any polymer-frame pistol — if correctly finished and assembled.

Before you go online and drop cash for your own Polymer80 kit, know this is a “project” kit — an exercise in building your own, off-the-books firearm. It’s not a lower-cost alternative to buying a new GLOCK. On the contrary, a Polymer80 kit plus all the GLOCK factory or aftermarket components you’ll need to complete the pistol will cost you more than would buying a new gun out of the dealer display case. Ours totaled $643.93 with standard GLOCK sights. It was $792.94 when we opted for the Tritium sights.

Compared to the going retail price for a Gen 4 G17, you can see this isn’t a bargain budget alternative. What it is, however, is a fun project letting you learn the intimate details of the GLOCK system while building a gun truly your very own! For some firearm fans, that, alone, is worth the price of admission.

For more info: https://www.polymer80.com Polymer80, Ph: (800) 517-1243