Bill Moran: Master of the Forge

Sharpened steel is one of man’s earliest and most useful tools. Keeping a keen edge can be one of life’s most frustrating mysteries for many. This is the very reason knives having long lasting edge holding abilities are cherished — particularly by those who don’t understand knife geometry and fail miserably trying to keep their blade sharp.

The Moran Way

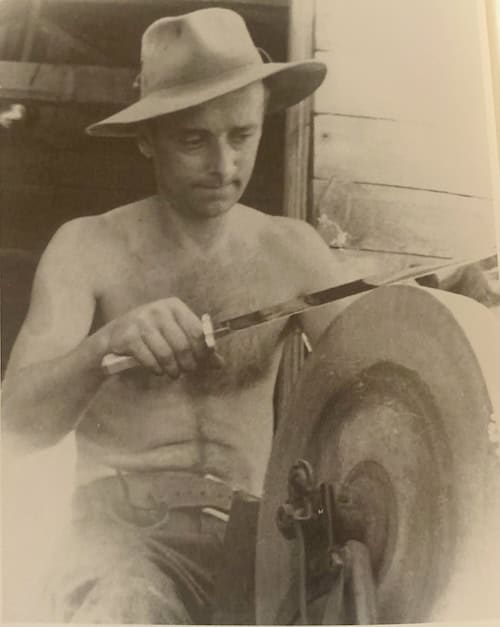

Bill Moran was a knifemaker born on May 1, 1925. He made his first knife at age 12 from his father’s crosscut saw. He figured when he started making knives, he could have as many knives as he wanted. By age 14, he was making knives for other people using a coal forge.

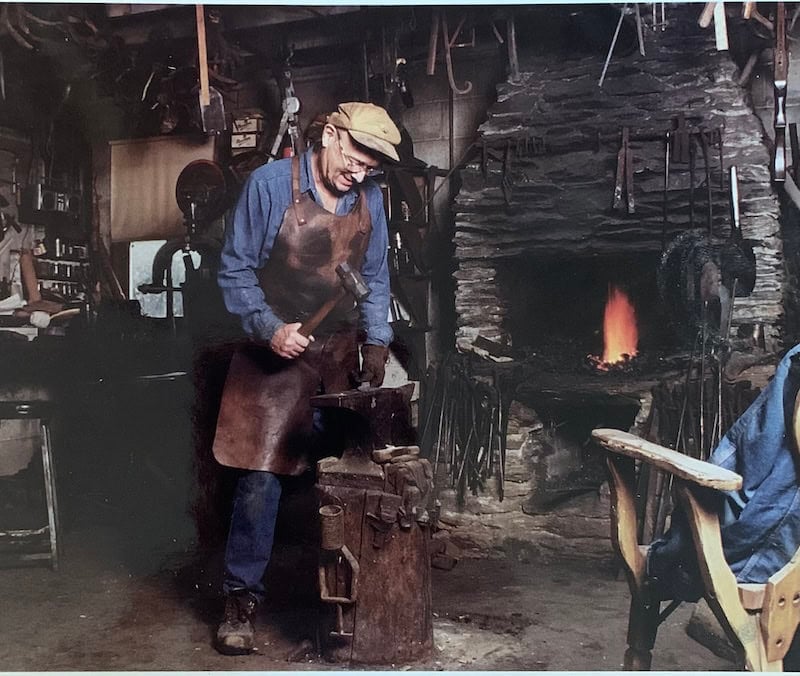

Bill’s knives were made the old-fashioned way. That is, he hand-forged his blades from long pieces of spring steel. He shaped his blades when the steel was heated cherry red and pounded them into shape, a little at a time.

The pounding not only shapes the steel but concentrates the blade grain at a molecular level, condensing the internal integrity and making the blade stronger and tougher. This process increases the blade’s edge-holding abilities.

It takes a keen eye to know how to forge a knife blade. Heat the metal too much, and the blade becomes brittle, not enough heat and you’ll never form your blade. It’s all in the color of the steel as it leaves the forge. Experience is the only teacher.

Early History

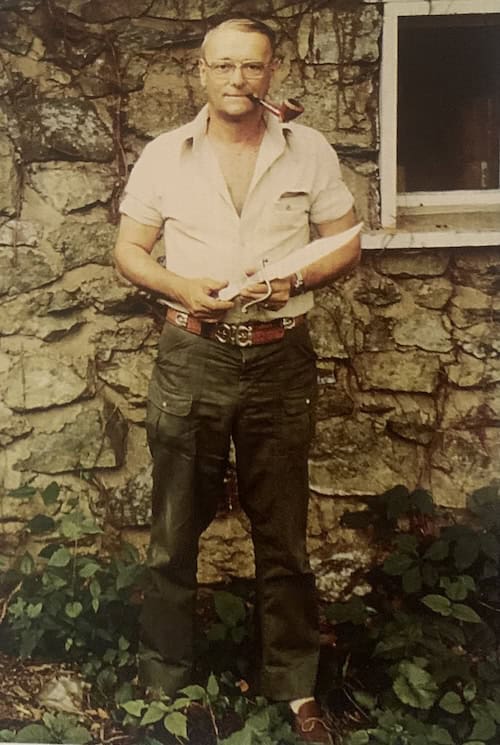

When I first became interested in knives many moons ago, the name Bill Moran always popped up in conversation and magazines. Born in Lime Kiln, Maryland, Moran’s birthplace is a mere ½ hours’ drive from my house. After he married his wife, Margaret, in 1968, he moved further up the road to Braddock Heights, Maryland, which is about 45 minutes from me. Here, Moran lived out his life with his wife, doing what he loved best: making hand-forged knives.

Moran didn’t make just any kind of blade. He made old-style, frontier-style knives with beautiful silver-inlaid maple handles and blades with stylishly sweeping bellies. His sheaths were made of wood and had intricate silver wire-inlaid designs. Besides being functional, his knives were works of art.

Damascus Steel

Moran had several other accomplishments, too. He’s most commonly known as the man who, after several years of research, rediscovered the technique of making Damascus steel.

Damascus steel is best described as welding several layers of different steels through hand forging, bending the steel in half, and rewelding the steel hundreds of times, blending the metals together, forming a distinctive pattern known for its unique looks, edge-holding abilities and sharpness.

Moran knew of the hundreds of years-old steel, but the process of making it was long lost. That is until Bill Moran unlocked the secret. Moran once wrote about Damascus: “The patterns are as different and individual as the human fingerprint. Each one has character and soul of its own.”

After years of trial and error, Moran made his first showing of modern Damascus steel in 1973. According to Moran, Damascus steel “brought back the forged blade” and “art knives.”

My Discovery

I first learned of Bill Moran’s knife-making exploits in the late 1980s. His knives were worth the prices they commanded, but they were well out of range for a young cop like me.

The best I could do back then was buy a Moran Camp Knife from Blackjack Knives, and even that purchase was a stretch for me. I still have the blade and cherish it with its famous “apple seed” grind on the blade for strength.

Bill Moran’s story is fascinating, and I have a deep respect for his blade-making skills and ingenuity in rediscovering Damascus steel. I’d read that Bill Moran’s knives were so sought after he’d quit taking orders because of the 10-to-15-year backlog. They’d fetch tens of thousands of dollars … and were worth every penny.

The American Bladesmith Society

Moran was also instrumental in the creation of the American Bladesmith Society, which he helped found in 1976. A not-for-profit group dedicated to preserving the forged blade and educating the public about traditional knife making, the ABS has grown to include knife makers and enthusiasts from around the world.

Lost Chance

In the late 80s, I was at a gun show at the Frederick County Fairgrounds. It was your typical gun show except for one thing. I met Bill Moran there. I don’t know who was more surprised, me for seeing Bill Moran, or him by me knowing who he was. He was very friendly and polite while talking with me. He recognized my sense of awe towards him and was good about it. He even invited me to come up to his shop and watch him “bang out” a few blades. This was one of my greatest regrets, as I never took him up on his offer, just figuring he was being nice to me. Boy, did I screw that one up!

Moran died of cancer on February 12, 2006, at Frederick Memorial Hospital. He is buried at Mount Olivet Cemetery in Frederick, Maryland. His wife preceded him in death. They had no children, and Moran left his estate to the NRA.

A few years later, my local gun shop had about a dozen Moran blades on consignment. Again, they were well out of my reach, but I got to handle and examine them daily for a few months. This was before the days of cell phones. Otherwise, I would have photographed those beauties.