Pistolsmithing: How to Be a Friction Fighter

The first thing I hear from most pistol owners is how they want a smoother and lighter trigger. I do countless trigger jobs each year. But it’s more than the hammer and sear that make for a smooth pistol action.

Trigger mechanisms and pistols, in general, are complex devices with many moving parts interfacing or connecting with other parts. This means they rub or move with other parts, levers and springs. It’s in this movement that friction is created. It may be slight, but it all adds up with the number of connections. When pistols are assembled at most factories, the goal is to assemble a safely functioning firearm — there is little time for fine-tuning.

Polish The Drag Out

Ispend much time smoothing and polishing each part and spring to reduce friction before even considering the obvious sear and hammer or sear and striker relationship. Most factory parts are etched with machine marks or stamping burrs, creating friction and drag when put together. The first thing is to study the relationship of the parts to one another. I never take a pistol apart without knowing how it works and is assembled. Once the areas of friction are identified, I try to isolate the friction using Dykem or soot. This allows me to work on just the points of friction or contact. Let’s be clear — this is not a “trigger job.”

Parts for polishing include the trigger bar, disconnector and or springs. Removing too much material can ruin a good part or make a pistol unsafe; this is more polishing than removing material — for example, the trigger bow on a 1911. The bow makes contact with the inner sides of the frame, contacts the disconnector at the rear, the pad or trigger shoe contacts the trigger track. Don’t forget magazines can rub the inside of the trigger bow. These areas can cause friction or drag, making for poor trigger feel.

I polish all the contact areas identified with Dykem on a soft buffing wheel coated with polishing compound. This results in a mirror finish for most points of contact. I file or mill the trigger pad to move freely in the track. Next, I polish the disconnector on the pad, which contacts the trigger bow, the head that rides in the frame tunnel. I check the tunnel for burrs.

In an S&W revolver, the rebound slide and spring create the most friction. These get lots of stoning and polishing. I check the pawl for contact with the side plate. I know this sounds like a lot, but remember these parts are cast, machined or stamped out by the thousands. Nicks and burrs abound. Polishing and smoothing are labor-intensive but worth it.

Lapping

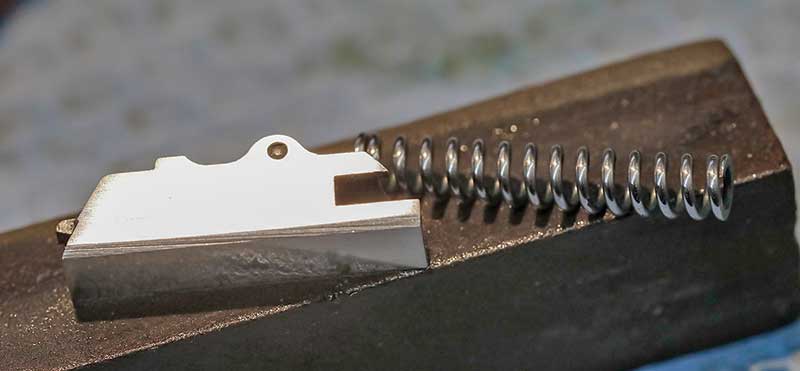

Another area that frequently bears on function is the slide to frame rail smoothness. Many models have contact with a barrel bushing. For these jobs, I turn to lapping. Lapping is a method of using an abrasive compound to burnish surfaces to one another. For lapping, use only non-embedding compounds like JB Bore Compound — my favorite. Non-embedding compounds will not clog the microscopic pores of the metal, and it washes off easily after use. I lap all my 1911 builds by hand after machine fitting. This results in a tight, buttery smooth fit. The barrel to bushing fit on 1911s is also an excellent area for lapping. A smoothly fit pistol functions better.

In many pistol models, springs travel in tunnels, like a firing pin spring or a mainspring. I polish these too, both the spring itself and the tunnel it travels in. Flex Hone brushes are an excellent choice for tunnels or tubes. The hone with many polishing bristles is on a long rod, which I place in a drill chuck to spin in the tube or tunnel. I place springs over a mandrel or rod and run them over a buffing wheel.

The sear and hammer or striker surfaces are essential to smooth trigger release. They typically need a very light touch to smooth them out. I can’t stress enough how little polishing or lapping should be done. In many cases, too smooth a surface is just as bad as a rough surface. Leave these to professionals with experience and the ability to test their work. No one wants an accidental discharge.